High Voltage Transmission Line

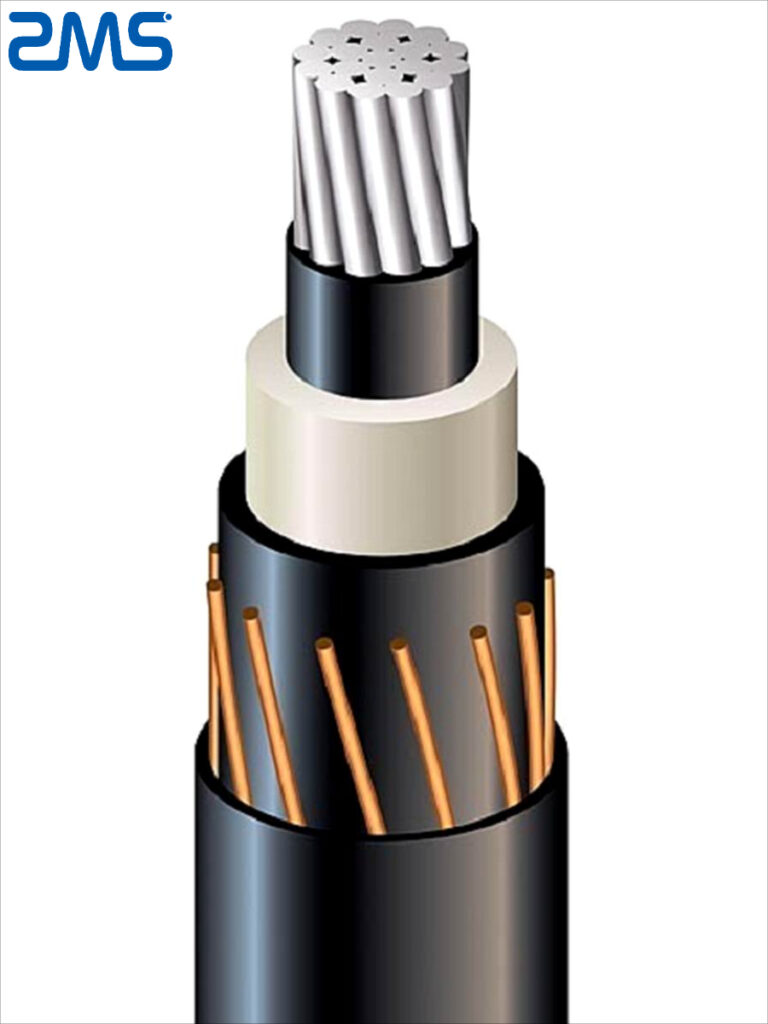

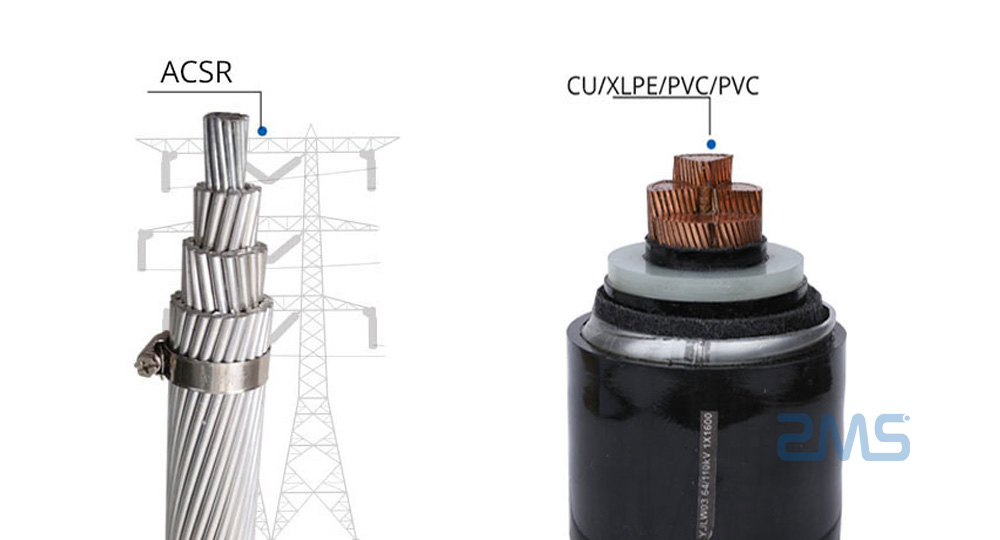

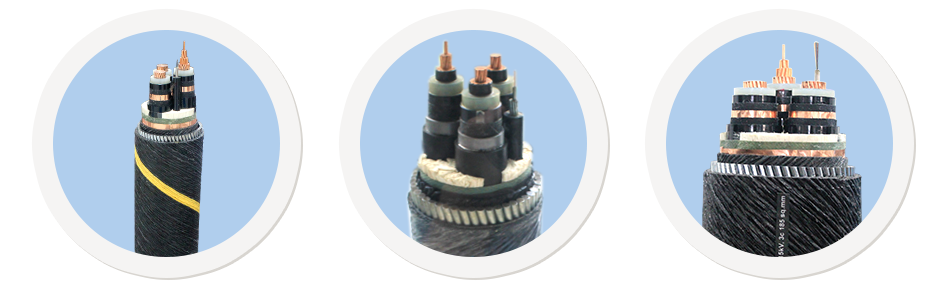

High Voltage Transmission Line’s overall structure from the inside to the outside of the components includes: conductor, insulation, inner sheath, filler (armored), outer insulation, the voltage level of 35 kilovolts or more, but more than 220 kilovolts can be regarded as ultra-high-voltage cables as well as ultra-high-voltage and so on.

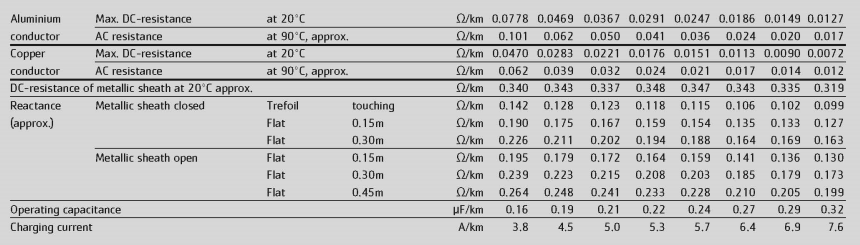

Descriptionof HV Cable Specifications

As a professional high voltage cable manufacturer, ZMS electrical power company brand has been synonymous with the longest life in medium and high voltage cable systems. No matter in design or manufacturing, we can provide reliable performance and lower maintenance costs to ensure the stable operation of your current and future long-term power transmission projects.

They are suitable for installation outdoors, underground, and in water. And then they are also suitable for installation in power stations, wind power stations, industrial, subsea power transmission, etc.

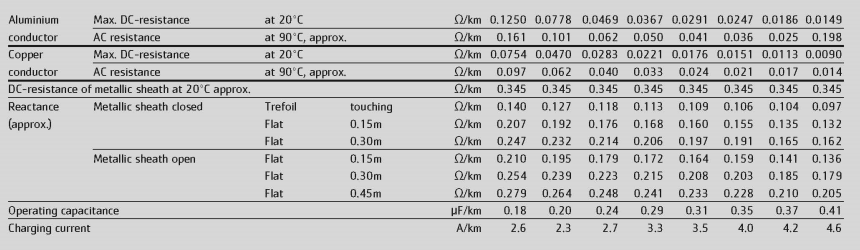

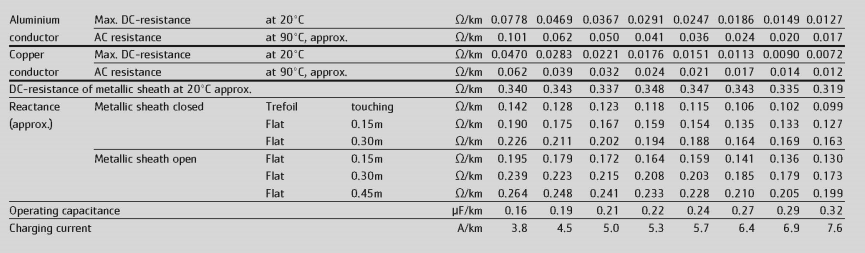

36/66kV Single Core XLPE Insulated HV Cables

Conductor: Longitudinal watertight solid aluminum rod

Conductor screen: Extruded semiconducting copolymer compound

Insulation: Extruded XLPE

Insulation screen: Extruded semiconducting copolymer compound

Bedding: Semiconducting water-blocking tapes

Metallic sheath: Extruded lead alloy

Outer sheath: Extruded PE

Standard: IEC 60840, IEC 60287, IEC 62067, ICEA S-108-720 and AEIC CS9.

76/132kV Single Core XLPE Insulated High Voltage Wire

Conductor: Longitudinal watertight stranded and compacted copper, including binder tape

Conductor screen: Extruded semiconducting copolymer compound

Insulation: Extruded XLPE

Insulation screen: Extruded semiconducting copolymer compound

Bedding: Semiconducting water-blocking tapes

Metallic screen: A layer of copper wire helix and a copper contact tape counter helix

Separation tape: Semiconducting water blocking and binder tapes

Radial water barrier: Aluminium foil laminate

Outer sheath: Extruded PE

Standard: IEC 60840, IEC 60287, IEC 62067, ICEA S-108-720 and AEIC CS9.

76/132kV Three Cores XLPE Insulated High Voltage Cable

Conductor: Longitudinal watertight segmental stranded and compacted copper, including binder tape

Conductor screen: Extruded semiconducting copolymer compound

Insulation: Extruded XLPE

Insulation screen: Extruded semiconducting copolymer compound

Bedding: Semiconducting water-blocking tapes

Metallic sheath: Aluminium welded sheath

Outer sheath: Extruded PE

Standard: IEC 60840, IEC 60287, IEC 62067, ICEA S-108-720 and AEIC CS9.

Selecting a Power Cable

Different kinds of HV cable constructions are required to transport electrical energy from the power station to the consumer. High-voltage cables must be rigorously selected for their insulation when buried in the ground. The following factors are important when selecting a suitable cable construction:

- Maximum operating voltage

- Insulation level

- Frequency

- Load carried

- Daily load curve

- Magnitude and duration of possible overload currents phase-to-phase and phase-to-earth

- Connection between overhead and cable line (direct connection or via transformer)

- Insulation level of equipment (bare conductor insulators, arresters, etc.)

- Voltage drop

- Length of line

- Profile of line

- Mode of installation:

– underground (ducted or non-ducted)

– overground (if in a tunnel, the dimensions and mode of ventilation of the tunnel) - Chemical and physical properties of the soil:

– whether rocky, sandy, clayey, or boggy; moist or dry

– chemical agents liable to cause corrosion etc.

– maximum thermal resistivity of the soil - Maximum and minimum ambient air and soil temperatures, taking into account adjacent hot-water pipes and other factors liable to heat the cables

- Specifications and requirements that apply

- The cable should be economical to use; an optimum cross-sectional area can be calculated based on the capital costs of the cable and running costs incurred by the power losses in the cable.

High Voltage Cable Catalog

ZMS HIGH VOLTAGE CABLE PDF

ZMS provides our partners around the world with brochures of our cable products, including aerial cables, submarine cables, control cables and other types of special cables, and more.

ZMS Cable Factory also manufactures accessories and connectors related to high voltage cable splicing and high voltage cable clamp. If you don’t know how to choose the product you need or can’t find the cable type and size you need on this page, don’t worry. Contact us and send us your requirements, and we can help you choose the right cable. You can provide us with the following information: cable voltage, conductor material, insulation and sheath material, shield type, armor type, etc. or you can provide us with cable installation environment, application requirements, etc. We will serve you wholeheartedly. ZMS cable supplier has several quality certifications: ISO 9000, ISO 9001, ISO14000, ISO14001, ISO18000, CE, IEC, BS, NFC, ASTM, DIN, etc.

Partnering with ZMS

ZMS has provided customized high voltage cable services for Thailand, model no: Underground power cable, rated voltage 115 kV,single-core, with copper conductor, XLPE insulation,copper wire screen,PE sheath, conductor size 300 mm2

ZMS has provided customized high voltage cable services to Singapore, model no: 132KV 1C*630 Sqmm UG Cu.Ar Cable. The production cycle was completed in just 45 days, and the warranty is guaranteed for 18 months.

ZMS Cables has long been a specialist in the production of shielded high voltage cables.ZMS cable production sets an example for the industry with unrivaled quality and precision. Every cable produced by ZMS is made with attention to detail to ensure optimum performance and reliability. We also have extensive experience in customizing cables, including ultra-high voltage cables from 66 kV to 500 kV, etc. This is a must-have advantage as a specialized supplier of high voltage cables.

Service of ZMS Company

Over Productions Service: ZMS has a wide range of cable and conductor products for you to choose from. We will provide caring services and professional project solutions for everyone who needs them.

Quality Certification Services: ZMS cable products are manufactured according to GB, IEC, BS, NFC, ASTM, DIN, and other international standards. Our technical team can customize cable products that meet your requirements according to your needs.

Profession Customer Service: ZMS provides free professional consulting services to provide you with one-stop project solution services and rapid product delivery solutions.

Delivery And Shipping Services: While we at ZMS provide high-quality cables, we also provide good delivery solutions. While ensuring the safe delivery of products, we provide the best packaging and transportation solutions, greatly reducing customers’ transportation costs.

Packaging of ZMS: ZMS cable packaging is provided in the form of wooden reels, corrugated boxes, and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.