IEC 60332 Cable

The IEC 60332 standard for cables is a standard for the flame resistance of single cables. To assess the flame retardancy of cables, the IEC has developed IEC60332-1, IEC60332-2, and IEC60332-3. IEC60332-1 and IEC60332-2 are used to assess the flame retardancy of single cables when they are placed inclined and vertically, respectively, and IEC60332-3 is used to assess the flame retardancy of bundled cables when they are burned vertically. IEC60332-3 is used to assess the flame retardancy of bundled cables when burned vertically, which is a higher requirement than when bundled cables are burned vertically. However, the IEC60332 cables produced by ZMS are safe and can pass the flame retardancy assessment of various standards.

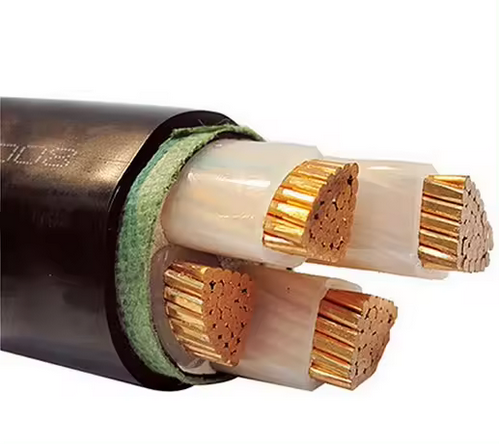

IEC60332 Cable Main Types

0.6/1KV Flame Retardant Armored Power Cable

Flame retardant cable is characterized by delaying the spread of flame along the cable so that the fire does not expand. Because of its lower cost, it is a large number of fire-resistant cables used in the cable species. Whether the cable is laid in a single cable or bundles, the spread of flame can be controlled within a certain range when the cable is burned. Therefore, it can avoid a major disaster caused by the cable fire extended combustion, thus improving the level of fire prevention of cable lines.

- Copper wire conductor

- XLPE insulation

- PP filler

- Non-woven fabrics wrapping

- PVC inner sheath

- Galvanized steel wire armouring

- Non-woven fabrics wrapping

- PVC outer sheath

0.6/1KV LOSH Flame-Retardant Power Cable

Low-smoke Zero Halogen cable is characterized not only by excellent fire retardant properties but also by the fact that the materials constituting the low-smoke halogen-free cable do not contain halogens. It is less corrosive and toxic when burned and produces a very small amount of smoke. This reduces the damage to the human body, instruments, and equipment, and facilitates timely rescue in case of fire.

Although the halogen-free low-smoke flame retardant cable has excellent flame retardancy, corrosion resistance, and low smoke concentration, its mechanical and electrical properties are slightly worse than those of ordinary cables.

Requirement of Application:

The permissible long-time working temperature of regular non-halogen low-smokie flame-retardant polyolefin insulation is not more than 70C, and that of irradiation cross-linked non-halogen low-smoke flame-retardant olefin insulation is not more than 105℃. The temperature of the laying cable is not lower than 0℃.

Fire-resisting Marine Shipboard Power Cable 0.6/1KV

The fire-resistant cable can maintain normal operation for a certain period in the case of flame burning and can maintain the integrity of the line (Circuit Integrity). Fire-resistant flame retardant cables produce less acid gas smoke when burning, and fire-resistant flame retardant performance is greatly improved, especially in the case of burning, accompanied by water spray and mechanical shock, the cable can still maintain the integrity of the line operation.

Conductor | Tinned or bare copper conductor, class 2/ Class 5(R) |

Insulation | Cross-Linked Polyethylene – XLPE(J) |

Screen | Metal/Polyester tape, copper wire braid (8 types) |

Inner Sheath | Thermoplastic polyolefin – SHFI (PF), Cross-linked polyolefin – SHF2 (PJ), PVC – ST2 (V) |

Armour | Copper wires braid (8), Steel wires braid (9) |

The Difference Between Flame Retardant Cables and Fire Resistant Cables

It is easy to confuse the concept of flame retardant cable and fire resistant cable. Although flame retardant cables have many advantages that are more suitable for chemical companies, such as low halogen, low smoke, and flame retardant. However, in general, fire-resistant cables can replace fire-resistant cables, while fire-resistant cables cannot replace fire-resistant cables. Their differences mainly lie in.

1. The Difference In Principle

The principles of fire-resistant cable and flame-retardant cable are different.

Halogen-containing cable flame retardant principle relies on the flame retardant effect of halogen, halogen-free cable flame retardant principle relies on the precipitation of water to lower the temperature to extinguish the fire roast.

Fire-resistant cable is to rely on the fire-resistant layer of mica materials, and fire-resistant properties to ensure that the cable works properly in the fire.

2. The Difference Between The Structure And Materials

Fire-resistant cable structures and materials and flame-retardant cables are not the same.

The basic structure of flame retardant cable is.

(1) The insulation layer is made of flame-retardant materials.

(2) The sheath and outer sheath are made of flame-retardant materials.

(3) The tape and filling using flame retardant materials.

Fire-resistant cable is usually between the conductor and insulation layer and then add a fire-resistant layer. So theoretically you can add a fire-resistant layer to the structure of the fire-retardant cable, it forms both fire-retardant and fire-resistant cable, but in practice, there is no need for this. Because the refractory layer of fire-resistant cable, usually uses a multi-layer mica tape wrapped directly around the wire. It can resist burning for a long time, and even if the polymer at the applied flame is burned, it can ensure the normal operation of the line.

Fire-Resistant Cable IEC Standards

To evaluate the fire resistance of cables, IEC60332-1, IEC60332-2, and IEC60332-3 have been developed by the International Electrotechnical Commission.

IEC60332-1 and IEC60332-2 are used to evaluate the flame retardancy of a single cable when it is placed at an angle and vertically, respectively.

IEC 60332-3 is used to evaluate the flame resistance of bundled cables when they burn vertically.

In contrast, the flame retardancy requirements for vertical burning of bundled cables are much higher.

IEC60332-1/BS4066-1 Flame Retardant Grade (Flame Test On Single Vertical Insulated Wires/Cables)

This is the flame resistance standard for a single cable. The test stipulates that a 60cm long specimen is fixed vertically in the metal box opened by the front wall, the flame length of 175mm propane burner from the upper fixed end of the specimen 450mm position on the flame cone. And the cable at an angle of 45 degrees, if the specimen burns damaged part of the lower part of the fixed end does not exceed 50mm, the test passes.

IEC60332-3/BS4066-3 flame retardant grade (vertical burning test for bundled wires or cables)

This is the flame retardant standard for bundled cables. The test stipulates that a 3.5m long cable specimen is fixed on a ladder test frame with wire, and the number of specimens is determined by the non-metallic materials required for different classifications.

The specimens are hung vertically on the back wall of the combustion furnace, and the air is introduced into the furnace through the air inlet on the bottom plate.

Propane plane burner with 750 ℃ flame contact with the specimen, the specimen in the case of forced blowing air (airflow emission 5 m3 / min, wind speed 0.9 m / s), must be in the vertical burning for 20 minutes without burning up.

The cable extinguishes itself within 2.5m of flame spread. IEC 60332 is divided into classes A, B, C, and D to evaluate the superiority of flame retardant performance.

Service of ZMS Company

Over Productions Service: ZMS has a wide range of cable and conductor products for you to choose from. We will provide caring services and professional project solutions for everyone who needs them.

Quality Certification Services: ZMS cable products are manufactured according to GB, IEC, BS, NFC, ASTM, DIN, and other international standards. Our technical team can customize cable products that meet your requirements according to your needs.

Profession Customer Service: ZMS provides free professional consulting services to provide you with one-stop project solution services and rapid product delivery solutions.

Delivery And Shipping Services: While we at ZMS provide high-quality cables, we also provide good delivery solutions. While ensuring the safe delivery of products, we provide the best packaging and transportation solutions, greatly reducing customers’ transportation costs.

Packaging of ZMS: ZMS cable packaging is provided in the form of wooden reels, corrugated boxes, and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.