MICC Cable

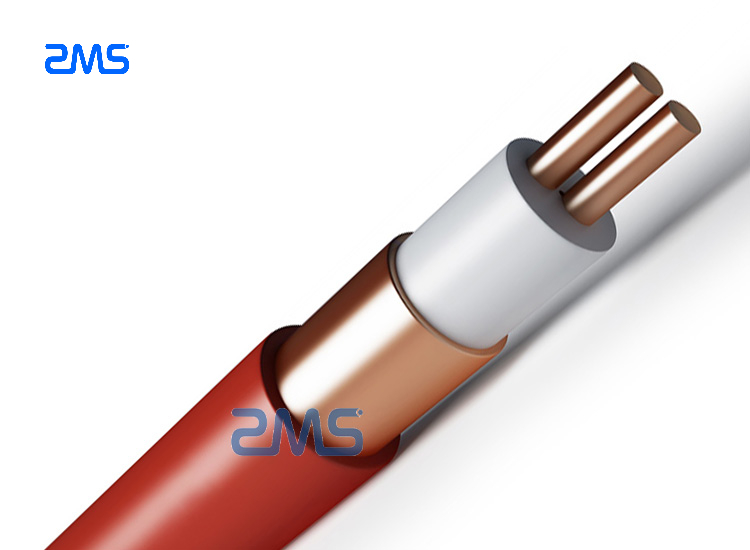

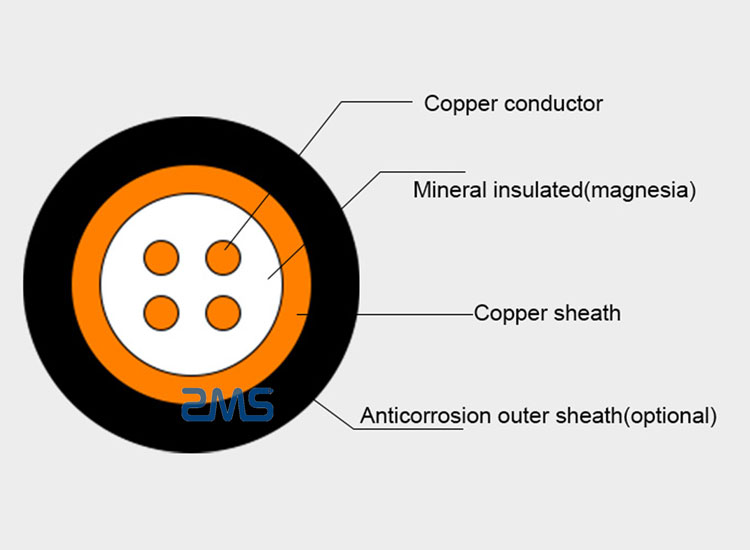

MICC cables, mineral insulated cables, are one of the most common fire-resistant cables, with annealed copper as the conductor, dense magnesium oxide as the insulation, and annealed copper tubing as the sheath.

The materials used by ZMS to produce mineral insulated copper cables are made from inorganic materials and therefore have some advantages that other cables do not have.

MICC Cable Types

MICC Cable --- Mineral Insulated Copper Clad Cable

- MICC Cable conductor: It is made of stranded copper wires with good bending characteristics.

- Insulation layer: Use high temperature resistant, non-combustible inorganic insulating material.

- Metal sheath: It is made of copper and copper alloy or stainless steel, which has good bending characteristics after special processing and can be used as a grounding wire.

- Outer sheath: Low-smoke non-toxic plastic material with good anti-corrosion properties.

Rated Voltage: 500V

Core: 1, 2, 3, 4, 7, 12, 19

Section(mm²): 1.0~4.0

- Rated Voltage: 750V

Core: 1, or 2, 3, 4

Section(mm²): 1~400 or 1~25

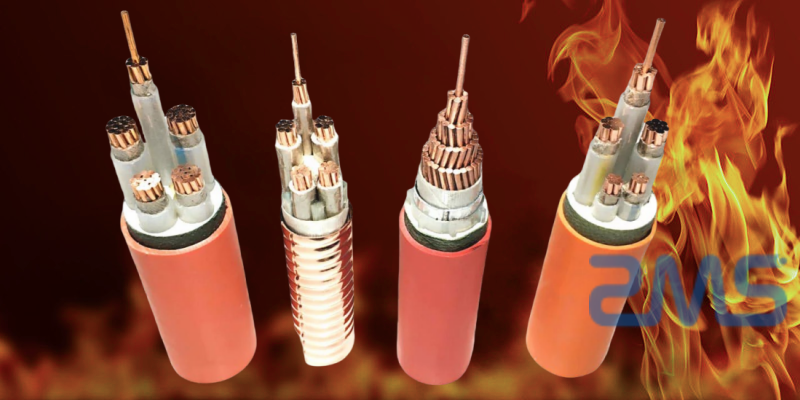

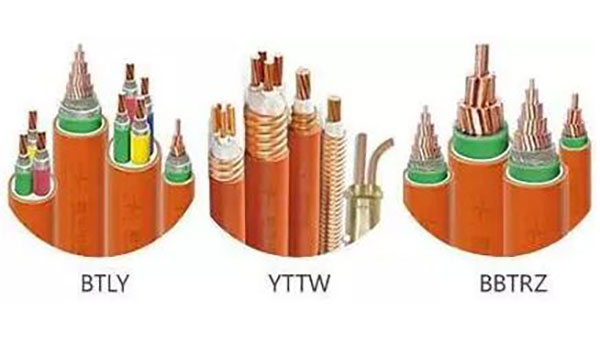

BBTRZ Flexible Mineral Insulated Cable

Mineral insulated copper sheathed cable consists of multi-stranded copper stranded wire, mica tape mineral insulation winding, alkali-free glass fiber dense filling, copper tape longitudinally wrapped and welded into a copper tube sheath.

BBTRZ Rigid Mineral Insulated Cable

BTT Series Mineral Insulated Copper cable is a mineral insulated cable for international workers. It is a kind of cable with a seamless outer sheath, filled with tightly compacted magnesium oxide crystal powder as insulation material in the middle.

Corrugated Copper Tape MICC Cable

MICC corrugated copper tape cables consist of a copper conductor, fluorinated mica tape insulation, and a corrugated copper tape cover. When it is required that the metal cover is not exposed, LSZH polyolefin sheath can be added.

About Mineral Insulated Cable, many specifications can be customized, partly as follows:

Specification(mm2) | Outer Diameter (mm) | Allowed continuous load capacity(A) | Allowable continuous soil loading(A) |

1*1.5 | 11 | 35 | 44 |

1*2.5 | 11.4 | 46 | 59 |

1*2.5 | 22.1 | 59 | 78 |

1*6 | 12.7 | 75 | 96 |

1*10 | 13.6 | 100 | 134 |

1*16 | 14.7 | 130 | 137 |

1*25 | 16.4 | 170 | 230 |

1*35 | 17.6 | 210 | 279 |

Application Of Mineral Insulated Cables

Mineral Insulated Cable Uses are intended to protect copper conductors from fire, moisture, and other hazards, and work primarily on the principle of using highly compressed magnesium oxide insulation.

- Public buildings: public entertainment venues, high-rise buildings, hotels, restaurants, hospitals, schools, large shopping malls, stations, airports, ports, and other places with a large flow of people.

- High-temperature places: transmission and distribution lines in the metallurgical industry, coke industry, shipbuilding factory, steel industry, glass industry, and other high-temperature occasions.

- Dangerous places: petrochemical industry, oil refinery, gas station, paint, and paint industry, chemical industry, nuclear power plant, natural gas, mining, and other places.

- Underground places: subways, underground warehouses, tunnels, underground squares, etc.

MICC wires are also known as MICC Fire Resistant Cables, so they are particularly suitable for use in high-rise buildings and public places to provide safety. As a professional supplier, we have supplied this cable in projects in UAE, Thailand, Nigeria, and other countries.

Related Accessories For MICC Cable Termination Kit

MICC cable accessories include mineral insulated cable tools, MICC cable glands, terminal blocks, grounding lugs, intermediate connector accessories, etc.

Advantages of ZMS MICC Cables

• Fire Protection: Mineral insulated cables are made of inorganic metallic copper and magnesium oxide powder, which do not cause fires in themselves and are unlikely to burn items that support combustion. In the event of a fire close to the melting point of copper, fireproof mineral insulated cables will continue to supply power.

• High Load Capacity: Among cables with the same cross-section, mineral insulated cables have a higher load capacity than mica-insulated and organic-insulated cables.

• Good Waterproof Performance: The copper sheath ZMS in mineral insulated cables is a seamless copper tube, so water molecules are completely blocked out, and the waterproof performance is excellent.

• Explosion-Proof: The copper sheath used in mineral insulated cables is a seamless copper tube and the magnesium oxide powder is tightly compacted. Flammable gases, oil vapors, and flames cannot reach the electrical equipment connected to the cable, so the cable is explosion-proof.

• Corrosion Resistance: Copper has good corrosion resistance and requires no additional protection under normal use. The plastic outer sheath enables corrosion resistance; therefore, the cable has good corrosion resistance.

• Resistance to Mechanical Damage: The conductor and metal sheath of mineral insulated cables have a certain degree of strength and toughness. When the cable is subjected to impact, bending, flattening, twisting, and other deformations, the sheath will not be damaged and no short-circuit effects will occur.

• Smoke-Free and Non-Toxic: The cable will not spontaneously combust under fire conditions nor produce smoke and toxic gases, which is a truly safe and environmentally friendly cable.

About ZMS Cable Manufacturer

Over Productions Service: ZMS has a wide range of cable and conductor products for you to choose from. We will provide caring services and professional project solutions for everyone who needs them.

Quality Certification Services: ZMS cable products are manufactured according to GB, IEC, BS, NFC, ASTM, DIN, and other international standards. Our technical team can customize cable products that meet your requirements according to your needs.

Profession Customer Service: ZMS provides free professional consulting services to provide you with one-stop project solution services and rapid product delivery solutions.

Delivery And Shipping Services: While we at ZMS provide high-quality cables, we also provide good delivery solutions. While ensuring the safe delivery of products, we provide the best packaging and transportation solutions, greatly reducing customers’ transportation costs.

Packaging of ZMS: ZMS cable packaging is provided in the form of wooden reels, corrugated boxes, and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.