Cable Specifications

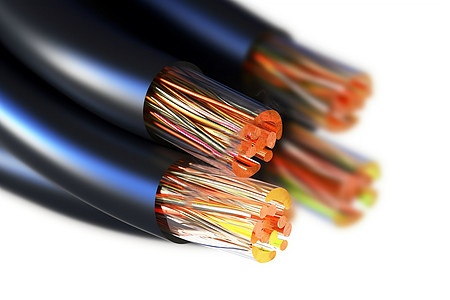

Cable Srandards are the meaning of the number of cores and cross-sectional size of wire and cable representation. The main wire and cable products used in power systems are overhead bare wires, busbars (busbars), power cables (plastic cables, rubber cables, overhead insulated cables), branch cables (replacing some busbars), electromagnetic wires, and electrical equipment wires and cables for power equipment.

ZMS cables can be manufactured to the most stringent standards in the world, including BS, CSA, IEC, VDE, and UL. And if you need a cable to suit your application or a custom-made special cable, our technical team is at your service to meet the best requirements for your project.

Cable Specification Types and Meanings

The codes of each part of the power cable types and their meanings

1. Insulation type: V- stands for polyvinyl chloride, X- stands for rubber, Y- stands for polyethylene, YJ- stands for cross-linked polyethylene, and Z- stands for paper.

2. Conductor material: L- stands for aluminum, T-(or omitted) stands for copper.

3. Inner sheath layer: V-representative of polychloroethylene sheath. y-polyethylene sheath. l-aluminum sheath. q-lead sheath. h-rubber sheath. f-neoprene sheath.

4. Characteristics: D-Non-drip. F-Phase.CY-Oil-filled. P-Oil-poor dry insulation. P-Shield. Z-DC.

5. Control layer:0-None. 2-Double steel tape. 3-Fine steel wire. 4-Coarse steel wire.

6. Outer sheath layer: 0-none. 1-fiber outer cover. 2-polychloroethylene sheath. 3-polyethylene sheath.

7. Flame-retardant cable in front of the code plus ZR. fire-resistant cable in front of the code plus NH.

Several Types of Commonly Used Cable Models and Their Use Occasions

VV Cable | Polyvinyl Chloride Insulation (VV Cable) PVC-sheathed power cables can be laid indoors, in tunnels, cable trenches, pipelines, and flammable and seriously corrosive places. |

| YJV Cable | Cross-Linked Polyethylene Insulation (YJV Cable) Polyvinyl chloride sheathed power cable can be laid indoors, in tunnels and pipelines, and can withstand a certain laying draw through. |

| ZR-VV Cable | Flame-Retardant Polyvinyl Chloride Insulation (ZR-VV Cable) The Flame-retardant PVC-sheathed power cable can be laid indoors, in tunnels, cable trenches, pipelines, and flammable and seriously corrosive places. |

| ZR-YJV Cable | Flame Retardant Cross-Linked Polyethylene Insulation (ZR-YJV Cable) Polychlorinated ethylene-sheathed power cable can be laid indoors, in tunnels, and pipelines, and can withstand a certain amount of laying traction. |

| NH-VV Cable | Fire-resistant PVC Insulation (NH-VV Cable) The PVC-sheathed power cable can be laid indoors, in tunnels, cable trenches, pipelines, and flammable and seriously corrosive places. |

| NH-YJV Cable | Fire-Resistant Cross-Linked Polyethylene Insulation (NH-YJV Cable) PVC sheathed power cable can be laid indoors, in tunnels and pipelines, and can withstand certain laying traction. |

| More Types | More Cable Types and Their Use Cases There are many more abbreviations for cable types. |

Cable Specifications Explained

BS standard is a British standard developed by BritishStandards Institution (BSI), an unofficial body with a high reputation internationally, established in 1901. It is the world’s first national standardization body, which is not controlled by the government but is strongly supported by the government. BSI develops and revises British Standards and promotes their implementation.

Overview of British Quality Certification

The British Standards Institute (BSI), formerly known as the British Engineering Standards Board, was established in 1901 as the body responsible for national quality certification in the UK.

In 1929, it was recognized by the “Royal Charter” and was officially renamed the British Standards Institute (BSI) in 1931. Although it is a private organization, it is entrusted by the state to be responsible for the unified management of national standardization work. Its supreme body is the Executive Council, under the mechanical, electrical, chemical, construction, textile, quality assurance, and other six sub-councils.

BSI headquarters has four working departments, and standardization department, the inspection department, the export bureau technical advisory department, and the quality assurance department. The Quality Assurance Department (QAD) is a permanent quality certification and mark management body. British quality certification work, not only for domestic services but also for international trade services.

More than 20% of the certification licenses issued by BSI are issued for products imported into the UK by foreign manufacturers. And accept the United States, Canada, Germany, New Zealand, and other countries commissioned by the certification organization, on behalf of the foreign certification mark.

Common Cable BS Standards

| Fixed installation cables (building wire) | BS6004 – PVC cables and wires for final building circuits, including double and grounding wires and meter tails |

| Low voltage distribution cables | BS5467 – XLPE or EPR insulated and PVC sheathed low voltage armored cables, typically used in construction and industrial applications |

| Control and instrumentation cables | BS6231 – Single-core panel cables commercially known as Class III, approved by UL and CSA |

| Medium and high voltage cables | BS6622 – Armoured medium voltage cables with XLPE or EPR insulation and PVC sheathing – 6.6kV to 33kV |

| Data and telecom cables | Covers various industry standards including IEC 11801, BS EN 50173, and TIA/EIA 568 |

| Fire resistant cables | BS7629-1 – Specification for 300/500V fire-resistant shielded cables with low smoke and corrosive gas emissions when affected by fire. Includes multi-core and multi-pair cables. |

| Cable Accessories | Extensive range of BASEC-approved cable accessories including cable lugs, cable sealing sleeves, and glands |

IEC standard is the International Electrical Commission (IEC), a worldwide standardization organization composed of national electrical committees, whose purpose is to promote the standardization of the world’s electrical and electronic fields. The origin of the IEC is a resolution adopted at an electrical convention held in St. Louis, USA, in 1904. IEC is the name of an organization, not a certification, and what we usually refer to as IEC certification is generally CB certification.

Overview of IEC Standards

After the establishment of ISO in 1947, IEC had been incorporated into ISO as an electrical division but still maintained its independence technically and financially.

According to the new agreement between ISO and IEC in 1976, both organizations are legally independent, and the IEC is responsible for international standardization work related to electrical and electronic fields, while other fields are handled by ISO. IEC member countries include the vast majority of industrially developed countries and a portion of developing countries. These countries have 97% of the world’s population, produce and consume 95% of the world’s electricity, and manufacture and use 90% of the world’s production of electrical and electronic products.

The purpose of the IEC is to promote the international unification of electrical standards, international cooperation in standardization and related aspects in the field of electrical and electronic engineering, and to improve mutual understanding between the international community. To achieve this purpose, various publications, including international standards, are published, and it is hoped that national committees will use these international standards when their national conditions permit. The IEC’s field of work includes electrotechnology in electricity, electronics, telecommunications, and atomic energy.

Common Cable IEC Standards

| IEC 60228 | Conductors for insulated cables |

| IEC 60331 | Testing of cables under fire conditions |

| IEC 60332 | Testing of cables and fiber optic cables under fire conditions |

| IEC 60502 | Extruded insulated power cables and cable accessories – 1kV to 30kV |

| IEC 60702 | Mineral insulated cables and their terminations – up to 750V |

| IEC 60754-1 | Testing of gases generated by burning cables. Part 1: Halogenated acid gases |

| IEC 60840 | Extruded insulated power cables and their accessories – 30kV to 150kV |

| IEC 61034 | Measurement of the smoke density of burning cables under specified conditions |

| IEC 61158 | Digital data communication for measurement and control. |

ZMS Cable can produce cable specifications of major brands, including Turkey, Portugal, South Korea, and other countries with electricity and production standards, if you have cable order requirements, please feel free to contact us.

Service of ZMS Cable Company

Over Productions Service: ZMS has a wide range of cable and conductor products for you to choose from. We will provide caring services and professional project solutions for everyone who needs them.

Quality Certification Services: ZMS cable products are manufactured according to GB, IEC, BS, NFC, ASTM, DIN, and other international standards. Our technical team can customize cable products that meet your requirements according to your needs.

Profession Customer Service: ZMS provides free professional consulting services to provide you with one-stop project solution services and rapid product delivery solutions.

Delivery And Shipping Services: While we at ZMS provide high-quality cables, we also provide good delivery solutions. While ensuring the safe delivery of products, we provide the best packaging and transportation solutions, greatly reducing customers’ transportation costs.

Packaging of ZMS: ZMS cable packaging is provided in the form of wooden reels, corrugated boxes, and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.