ACSS Cable

ACSS/TW Conductor is a type of HTLS conductor. It is primarily used for overhead distribution and transmission lines. It is designed for continuous operation at temperatures up to 250°C without loss of strength. Under electrical load, it sags less than comparable ACSR. Moreover, its final sag is not affected by the long-term creep of aluminum. These points make ACSR particularly useful in reconstruction. In new overhead line applications, structural savings and increased current carrying capacity are possible due to reduced conductor sag.

ACSS Conductor Specifications

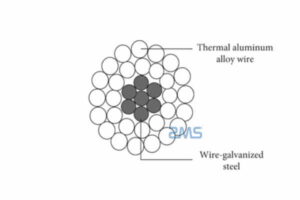

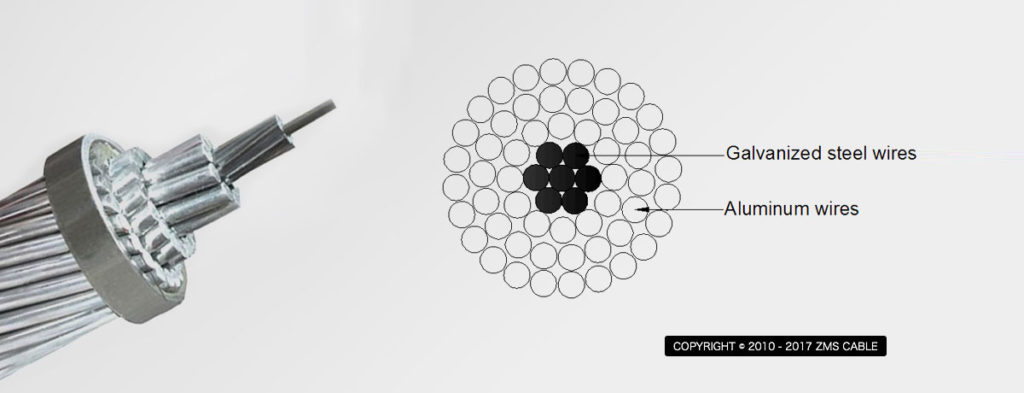

ACSS/TW, a nonhomogeneous conductor, consists of a round aluminum 1350-O wire and a round-coated steel core. The steel core carries most or all of the mechanical load of the conductor. The steel core wire is coated with a zinc-5% aluminum-mixed rare earth alloy layer to prevent corrosion. We can customize corrosion protection to suit your actual conductor exposure environment.

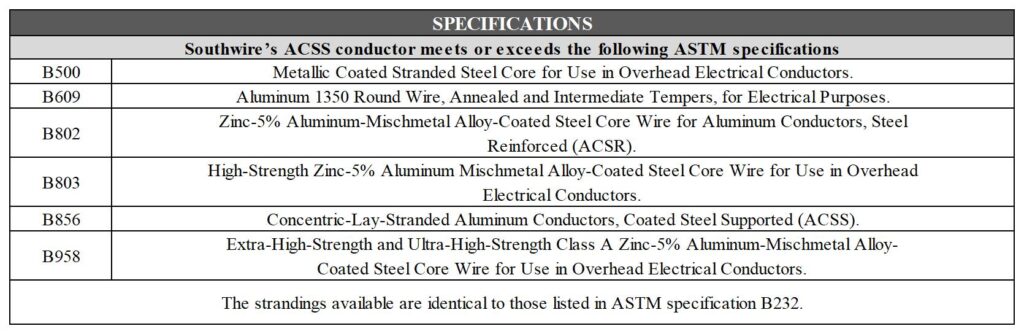

Standard

Q320623 AP 32, IEC 61089, IEC 62219, ASTM B609, ASTM B851, ASTM B856, ASTM B857

Features of HTLS Conductors from ZMS

- Low conductor arc sag at high temperatures, high return temperatures, and low resistance.

- Replacement of conventional conductors without or with minor adjustments to steel tower structures or line corridors.

- Significantly increases the load capacity of transmission lines.

- Applications in transmission capacity increase where conductor strength loss (thermal limiting) and exceeding clearance limits (gap limiting) are considered, and conductor temperature is limited to a certain temperature.

Aluminum Conductor Steel Supported (ACSS) manufactured by ZMS has extensive experience in both material and conductor stretching. The conductor advantages are suitable for applications such as re-conductor applications where increased current is required under existing tension and clearance conditions; new line applications where structural savings can be realized due to reduced conductor sag; new line applications where high contingency loads are required; and lines with vibration-loving problems.

Selecting the Right ACSS Conductor

If you are confused about the construction and materials used in the selection of ACSS conductors, for example, you may be torn between ACSS conductors and the common overhead ACSR conductors, please feel free to consult with the cable professionals at ZMS.

Aluminum-core steel-reinforced cable (ACSR) is a high-capacity, high-strength stranded conductor typically used for overhead power lines. The outer strand is high-purity aluminum, selected for its good electrical conductivity, lightweight, low cost, corrosion resistance, and good resistance to mechanical stress. Steel also has low elastic and inelastic deformation due to low coefficients of thermal expansion under mechanical loads (e.g. wind and ice) as well as current loads. These properties make ACSR sag significantly less than all aluminum conductors.

ACSR cables still depend on the tensile strength of aluminum, which is only reinforced by steel. As a result, their continuous operating temperature is limited to 75 °C, which is the temperature at which aluminum begins to anneal and soften over time. Cables that rely entirely on steel for their strength and can therefore be used at temperatures up to 250°C are called Aluminum Conductor Steel Support (ACSS).

Common HTLS Arc Conductors Include

Today’s increased demand for electricity, the increasing difficulty of erecting the line corridors required for new overhead lines, and the rapid rise of renewable energy generation. There is an urgent need for transmission upgrades and transmission expansion. High-temperature low sag conductors (HTLS conductors) are a new technology for upgrading transmission lines to increase the thermal rating to improve transmission capacity. HTLS conductors can operate at high temperatures (100 °C and above) for extended periods without significant deterioration in tensile strength or other mechanical, electrical, or chemical properties. The tensile length at the same temperature is significantly lower than that of conventional aluminum or steel core aluminum conductors.

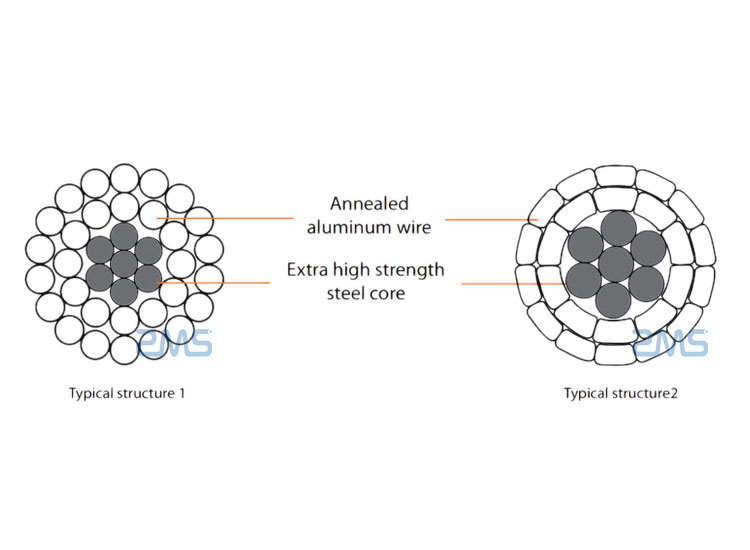

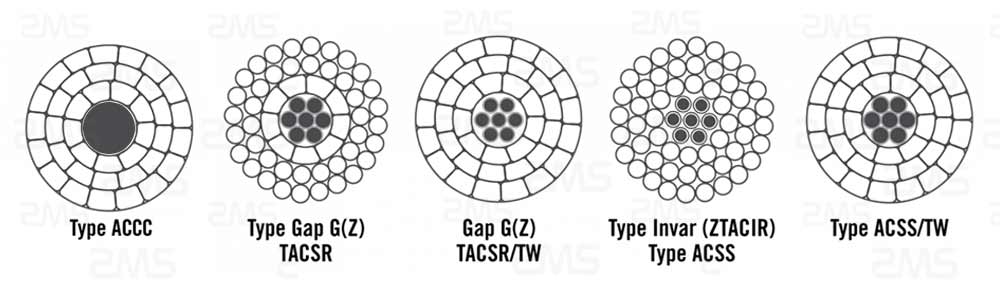

1. ACSS and ACSS/TW—(aluminum conductor steel supported/Trapezoidal wire, ACSS/TW), trapezoidal/steel core soft aluminum stranded wire. Annealed aluminum stranded wire + conventional steel core, operating temperature up to 250 °C.

2. G(Z)TACSR—(Gap-type Thermo-resistant Aluminum Alloy Conductor Steel Reinforced). Gap-type steel core heat-resistant aluminum alloy strand, the operating temperature can reach 150℃.

3. Invar Conductor—(Z)TACIR-ZTA1(Extra heat-resistant) Aluminum Conductor Invar Steel Reinforced. 210℃.

4. ACCR—(Aluminum Conductor Composite Reinforce). Aluminum-based ceramic fiber core aluminum strand, continuous operation temperature 210℃, short time 240℃.

5. ACCC—(Aluminum Conductor Composite Core). Soft aluminum stranded wire with a carbon fiber core, continuous running temperature 180℃.

Service of ZMS Company

Over Productions Service: ZMS has a wide range of cable and conductor products for you to choose from. We will provide caring services and professional project solutions for everyone who needs them.

Quality Certification Services: ZMS cable products are manufactured according to GB, IEC, BS, NFC, ASTM, DIN, and other international standards. Our technical team can customize cable products that meet your requirements according to your needs.

Profession Customer Service: ZMS provides free professional consulting services to provide you with one-stop project solution services and rapid product delivery solutions.

Delivery And Shipping Services: While we at ZMS provide high-quality cables, we also provide good delivery solutions. While ensuring the safe delivery of products, we provide the best packaging and transportation solutions, greatly reducing customers’ transportation costs.

Packaging of ZMS: ZMS cable packaging is provided in the form of wooden reels, corrugated boxes, and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.

More Information