HTLS conductor cable, or high-temperature low-sag conductor cable, is a type of electrical conductor that is used in high-voltage power transmission lines.

It is designed to operate at high temperatures without losing its mechanical strength or electrical conductivity.

This allows the cable to carry high currents over long distances without sag, which can reduce the overall efficiency of the transmission line.

There are several types of HTLS conductor cables, each with its unique characteristics and applications.

Some of the most common types include:

AC HTLS conductor cable

This type of cable is designed for use in alternating current (AC) power transmission systems.

It consists of multiple strands of aluminum or aluminum alloy, which are twisted together to form a single conductor.

The strands are coated with a layer of insulation, such as polyethylene or cross-linked polyethylene, to prevent electrical leakage and provide mechanical support.

AC HTLS conductor cables are typically used in high-voltage power transmission lines, where they can operate at temperatures up to 200 degrees Celsius without losing their strength or conductivity.

DC HTLS conductor cable

This type of cable is designed for use in direct current (DC) power transmission systems.

It consists of a single strand of copper or copper alloy, which is coated with a layer of insulation to prevent electrical leakage and provide mechanical support.

DC HTLS conductor cables are typically used in high-voltage DC transmission lines, where they can operate at temperatures up to 250 degrees Celsius without losing their strength or conductivity.

Composite HTLS conductor cable

This type of cable is a combination of AC HTLS and DC HTLS conductor cables.

It consists of multiple strands of aluminum or aluminum alloy, which are twisted together to form a single conductor.

The strands are coated with a layer of insulation, such as polyethylene or cross-linked polyethylene, to prevent electrical leakage and provide mechanical support.

The composite HTLS conductor cable also contains a single strand of copper or copper alloy, which is coated with a layer of insulation to provide additional conductivity and mechanical support.

Composite HTLS conductor cables are typically used in high-voltage transmission lines, where they can operate at temperatures up to 250 degrees Celsius without losing their strength or conductivity.

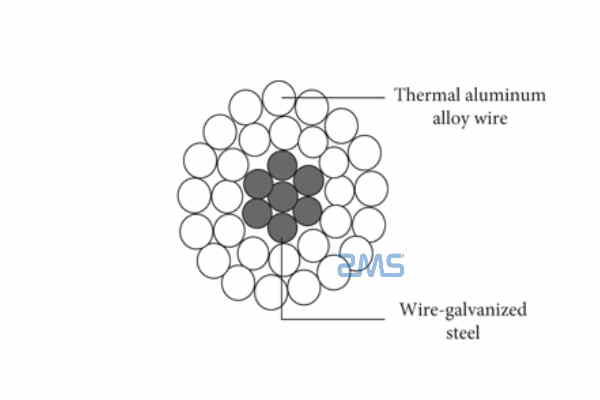

Concentric HTLS conductor cable

This type of cable is a variation of composite HTLS conductor cable.

It consists of multiple strands of aluminum or aluminum alloy, which are twisted together to form a single conductor.

The strands are coated with a layer of insulation, such as polyethylene or cross-linked polyethylene, to prevent electrical leakage and provide mechanical support.

The concentric HTLS conductor cable also contains a single strand of copper or copper alloy, which is coated with a layer of insulation to provide additional conductivity and mechanical support.

The copper strand is arranged concentrically around the aluminum conductor, forming a “core-shell” structure.

Concentric HTLS conductor cables are typically used in high-voltage transmission lines, where they can operate at temperatures up to 250 degrees Celsius without losing their strength or conductivity.

Summary

Overall, HTLS conductor cables are an important component of high-voltage power transmission systems.

They are designed to operate at high temperatures without losing their mechanical strength or electrical conductivity, which allows them to carry high currents over long distances without sag.

Different types of HTLS conductor cables are suitable for different applications, depending on the type of power transmission system and the operating conditions of the transmission line.