EV Charging Cable

Electric EV Charging Cable is used to connect the electric vehicle charging device with the charging infrastructure, to transmit power to the electric vehicle, and is equipped with a certain number of signal lines, control lines, power supply auxiliary lines, etc. to ensure that the entire charging process is controlled accurately and operated safely and without error.

ZMS Electric Vehicle Charging Pile Cable Performance

- Oil resistance: excellent, excellent resistance to chemicals, acids, alkalis, solvents, and various hydraulic fluids.

- Weathering resistance: excellent UV and sunlight aging resistance, suitable for outdoor use.

- Flame retardant performance: comply with IEC standards. Adopting a unique structure, specifications can be customized.

EV Charging Cable Specification

With the rapid development of trams and new energy trams, there are various charging methods for trams, so many factors need to be considered when choosing the specifications and types of EV charging cables.

UL Listed Charging Cables

Product Standard: UL62

Material: Insulation: TPE, PVC

Sheath: TPE, PVC

Rated temperature: -40℃~105C

Rated voltage: 300V, 600V

| Certified Series | Cable Specifications | Voltage | Reference Current | Material Temperature Resistance Grade | Color |

| EVE EVT | 3×10AWG+2×16AWG | 600V | 32A | -40℃~105℃ | Orange/Black |

| 2×8AWG+10AWG+2×16AWG | 600V | 46A | -40℃~105℃ | Orange/Black | |

| 2×6AWG+8AWG+2×16AWG | 600V | 63A | -40℃~105℃ | Orange/Black | |

| 2×3/0AWG+4AWG+2×12AWG | 600V | 260A | -40℃~105℃ | Orange/Black | |

| The specification is more than 2 cores 18AWG~500kcmi1, 1~2 cores control wire can be added, the specific parameters of the products are subject to the technical drawings. | |||||

TÜV Certified Charging Cables

Product Standard: 2Pfg1908

Material: Insulation: TPE

Sheath: TPE

Cable Characteristics: Ambient Temperature: -25℃~50℃(Maximum Temperature: 60℃)

Rated voltage: 450/750V

| Certified Series | Cable Specifications | Voltage | Reference Current | Material Temperature Resistance Class | Color |

| EV07EE-H EV07EEC4E-H | 3×2.5mm²+1×0.75mm | 450/750V | 16A | -40℃~105℃ | Black |

| 3×6.0mm²+1×0.75mm | 450/750V | 32A | -40℃~105℃ | Black | |

| 2×16mm²+2×0.75mm² | 450/750V | 64A | -40℃~105℃ | Black | |

| 2×35mm²+2×0.75mm² | 450/750V | 125A | -40℃~105T | Black | |

| 2×70mm²+2×0.75mm² | 450/750V | 250A | -40℃~105℃ | Black | |

| EV07EE-H | 5×13.3mm²+(1~2)×(0.5~2.5mm²) | 450/750V | 63A | -40℃~105℃ | Black |

| The specification is 2~5 cores 1.0mm²~95mm², 1~4 cores 0.5mm*~0.75mm* control wires can be added, the specific parameters of the products are subject to the technical drawings. | |||||

CQC DC Certified Charging Cable

Product Standard: CQC1103-2014, CQC1105-2014

Insulation: TPE

Sheath: TPE, TPU

Ambient Temperature: -40°C~50°C

Rated voltage: 1000V

| DC Certification Series | Cable Specifications | Voltage | Reference Current | Product Temperature Rating | colar |

| EVDC-SS EVDC-SSPS EVDC-S90 EVDC-S90S90U | 2×16mm+2×4.0mm+2×0.75mm | 1000V | 63A | 40℃~105℃ | Orange/Black |

| 2×35mr+2×4.0mm+2×0.75mm | 1000V | 125A | -40℃~105℃ | Orange/Black | |

| 2×70mm+2×6.0mm+4×1.5mm² | 1000V | 250A | -40℃~105℃ | Orange/Black | |

| 2×95mm+2×6.0mm+4×1.5mm² | 1000V | 280A | -40℃~105℃ | Orange/Black | |

| Specifications for 2-core 10mm² ~ 95m², low-voltage auxiliary power supply for 2-core 4.0mm ~ 6.0mm ², can add 1 ~ 4-core 0.5mm ~ 2.5mm ² control and signal lines, control and signal lines can be shielded or bus shielding, the specific parameters of the product in accordance with the technical drawings. | |||||

The above product specifications, dimensions, structure may be changed due to technological advances, similar specifications can be designed and manufactured according to customer demand for use.

Performance Of Electric Vehicle Charging Cable

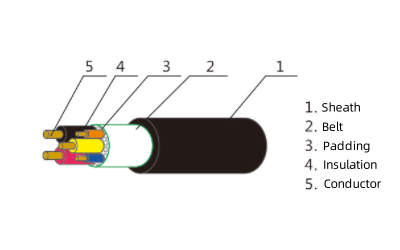

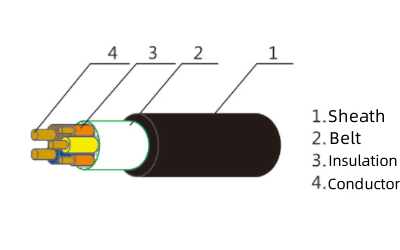

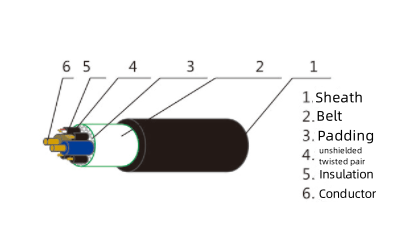

The electric vehicle charging cable is the carrier connecting the electric vehicle and the charging port, and its basic function is to transmit electric energy. It is also equipped with a certain number of signal lines, control lines, power supply auxiliary lines, etc. to ensure that the whole charging process is controlled accurately and operated safely and without errors. The most important thing is to ensure the safety of the charging cable, and the structure that has the closest relationship with its safety is the insulation structure and the structure of each protective layer. Therefore, the key processes are the insulation process and the protective layer process.

Considering the mechanical, electrical, and operational requirements of charging cables, ZMS cable manufacturers have adopted new low-smoke, halogen-free flame retardant materials, polyester elastomers, polyurethane materials, etc., which are more suitable for insulating and sheathing materials of electric vehicle EV charging cables. This has become a key development direction for charging cable products.

The new halogen-free materials, because of the absence of halogens, do not produce harmful and corrosive gases when burning. It also has less smoke emission and good flame retardant and mechanical properties, which can make the electric vehicle charging cable used for a longer time.

Testing the Quality of Electric Vehicle Charging Cables

Electric Vehicle Charging Cable

Electric Vehicle Charging Plug

To be able to use the process of excellent performance, you need to know how to select and measure the quality of the wire.

You can choose a good reputation electric car high voltage cable to achieve high quality charging demand for new energy vehicles. And to ensure that the rated current in the continuous charging works for a long time.

This will reduce the bad phenomenon in the charging process and can also improve the life of the wire.

Measure the quality of the wire mainly depends on several aspects.

1. Withstanding Ability

The ability to withstand the use process is critical and affects the quality of performance. The quality of the wire can be measured by understanding its overall resistance to heat crushing and corrosion resistance. As the wire is used in different environments, only good resistance can highlight the use quality. And can be used in the long-term security process and will not be easily damaged.

2. Bending Radius Degree

In measuring the electric car high voltage wire can also be measured by looking at the bending radius of the wire to measure. The charging operation of the car is often adjusted according to the different vehicle’s charging. Wire bending radius degree of good wire to achieve the needs of different car charging, bending degree can also protect the wire from being broken or broken skin and other phenomena. As well as the use of the process of charging flexibility.

3. The Quality of Copper is Good or Bad

The car wire can also be identified by looking at the quality of copper to identify the quality. Good copper wire not only has a long service life and high security but can be fast when charging. Good copper wire both good electrical conductivity and energy saving, reducing charging costs. Therefore, the quality is mainly determined by the quality of the copper.

ZMS Cable Service

Over Productions Service: ZMS has a wide range of cable and conductor products for you to choose from. We will provide caring services and professional project solutions for everyone who needs them.

Quality Certification Services: ZMS cable products are manufactured according to GB, IEC, BS, NFC, ASTM, DIN, and other international standards. Our technical team can customize cable products that meet your requirements according to your needs.

Profession Customer Service: ZMS provides free professional consulting services to provide you with one-stop project solution services and rapid product delivery solutions.

Delivery And Shipping Services: While we at ZMS provide high-quality cables, we also provide good delivery solutions. While ensuring the safe delivery of products, we provide the best packaging and transportation solutions, greatly reducing customers’ transportation costs.

Packaging of ZMS: ZMS cable packaging is provided in the form of wooden reels, corrugated boxes, and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.