Submarine Cable

Submarine Cables’ three main markets for ZMS are offshore oil, transoceanic power transmission, and offshore wind. Marine cables are used in special applications and therefore have more stringent quality requirements. As we at ZMS Power continue to grow and develop, the functional range of specialty cables is also expanding, so you will always find a specialty cable that meets your specific requirements. If there is no special cable that meets your requirements, we can customize cables with special characteristics for your particular application to achieve your specific purpose or task.

Kind of the Submarine Cable Products

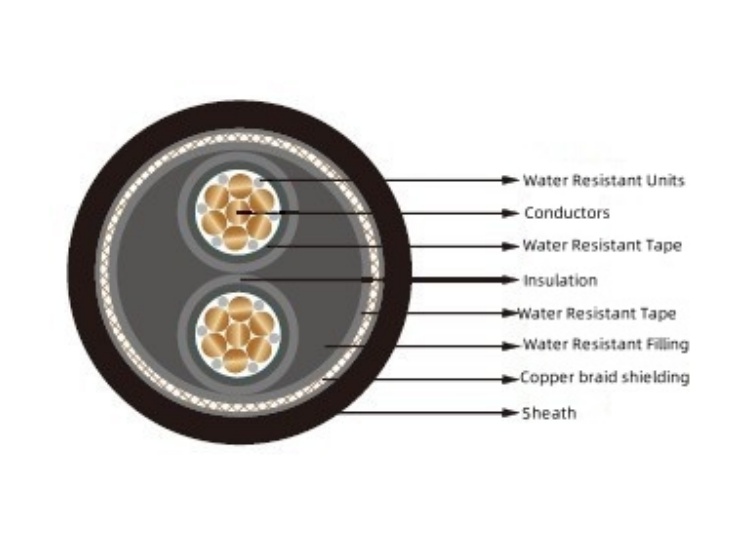

Low Voltage Water-Blocking Submarine Cable

This type of cable has water-blocking properties and is suitable as an outboard installation cable for ships.

Conductor: Multi-stranded fine copper wire.

Unit: water-blocking unit.

Separation: water-resistant tape.

Insulation: Special elastomer.

Filling: Water-resistant filling.

Separation: Water-resistant tape.

Shield: Tinned copper braid.

Standard: GB/T14049-2008, IEC60502- 2004

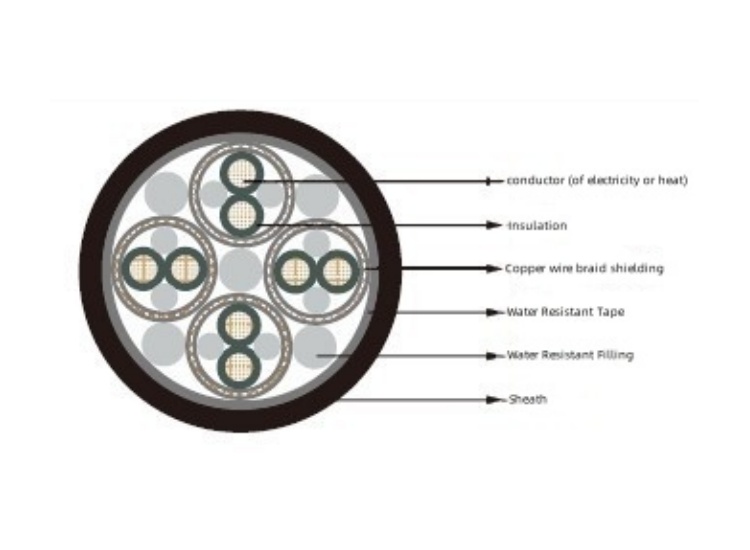

LV Single Pair Shielded Partially Longitudinal Water-Resistant Cable

The ship’s outboard mounted cable is water-blocked horizontally, fully water-blocked vertically, and all cores are not water-blocked.

Conductor: Multi-stranded fine copper wire.

Insulation: special elastomer.

Cable forming unit: twisted pair.

Individual shielding: Tinned copper braid single-pair shielding.

Filling: Water-resistant filling.

Separation: Water-resistant tape.

Jacket: Cross-linked halogen-free flame retardant material.

Standard: VG 95218 part 29

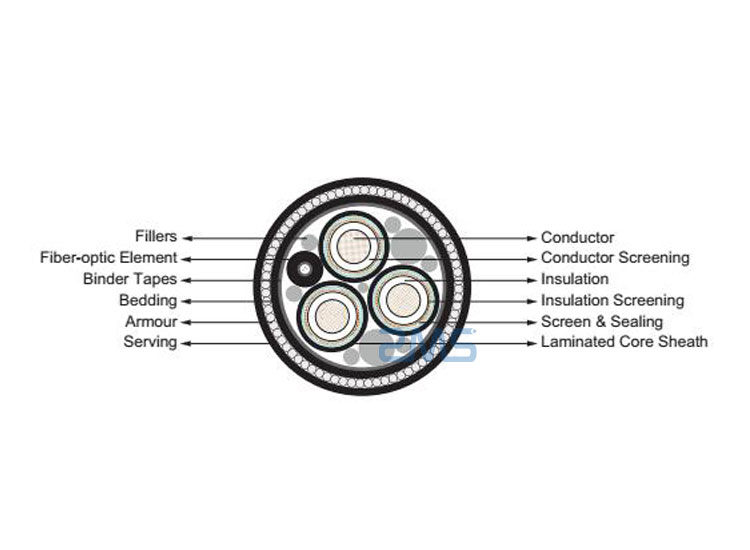

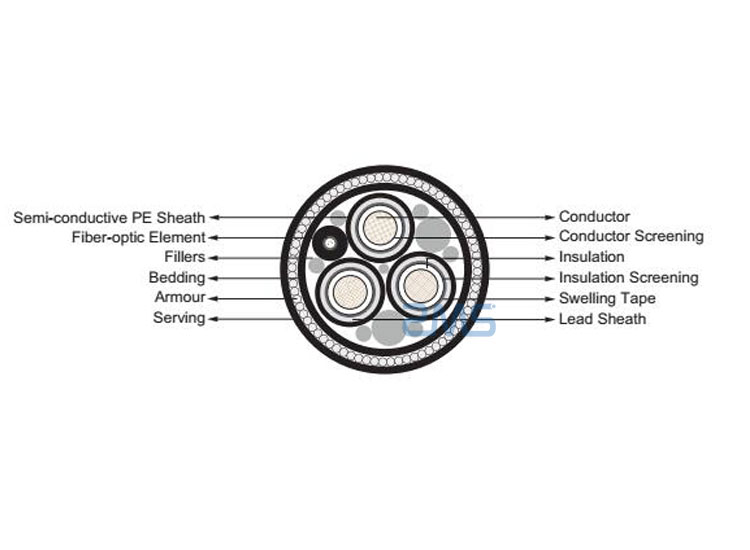

XLPE Insulated AC Medium Voltage Undersea Fiber Optic Cable

The submarine cables are used to transmit power to coastal islands, oil platforms or to cross rivers and lakes. The cable design is based on national or international standards or on the customer’s design and standards.

Conductor: Compact round multi-strand copper conductor, water resistant.

Conductor shielding: extruded semi-conductive material.

Insulation Shield: Extruded semi-conductive material.

Shield: Copper wire and copper tape spiral, expanded powder.

Crimp core-sheath: aluminum tape bonded PE sheath.

Filling: Polypropylene filling.

Fiber optic unit: fiber optic cable.

Padding layer: polypropylene fiber.

Armor: Galvanized steel wire.

Sheath: burlap tape, bituminous material, polypropylene fiber.

Standard: IEC 60228; IEC 60502;IEC 60840; IEC 62067

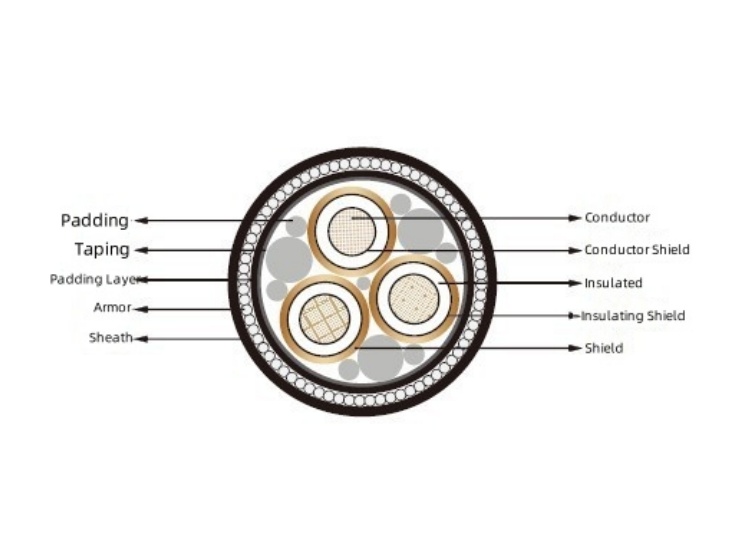

EPR Insulated AC Medium Voltage Submarine Cable

The submarine cables are used to transmit power to coastal islands, oil platforms or to cross rivers and lakes.

Conductor: Compact round multi-strand copper conductor, water resistant.

Conductor shielding: extruded semi-conductive material.

Insulation Shield: Extruded semi-conductive material.

Shield: Copper tape.

Filling: Polypropylene filled.

Separation: Taping.

Padding: Polypropylene fiber.

Armoring: Galvanized steel wire.

Sheath: burlap tape, bituminous material, polypropylene fibers.

Standards: VDE, IEC, and ICEA, or according to customer’s design and standards.

Lead Sheathed AC High Voltage Undersea Cable

These submarine cables are used to carry electricity to coastal islands, oil platforms, or across rivers and lakes. We also provide targeted solutions for cable systems and offshore installations.

Conductor: Copper conductor, water resistant.

Conductor shielding: extruded semi-conductive material.

Insulation Shield: Extruded semi-conductive material.

Separation: Expansion tape.

Core sheath 1: Lead sheath.

Core Sheath 2: Semi-conductive PE sheath.

Filling: Polypropylene filling.

Fiber unit: Optical fiber cable.

Armor: Galvanized steel wire with bituminous material filling.

Standard: IEC 60228; IEC 60502;IEC 60840; IEC 62067

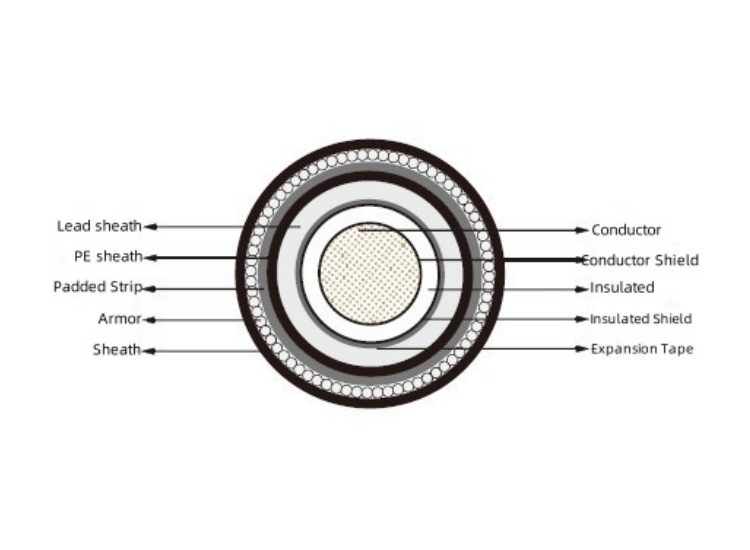

XLPE Insulated DC High Voltage Submarine Cable

This submarine cable is used to carry electricity to coastal islands, oil platforms or across rivers and lakes.

Conductor: Copper conductor, water resistant.

Conductor shielding: extruded semi-conductive material.

Insulation Shield: Extruded semi-conductive material.

Separation: Expansion tape.

Core sheath 1: Lead sheath.

Core wire sheath 2: PE sheath.

Liner: Liner layer.

Armouring: Galvanized steel wire filled with bituminous material.

Sheath: Polypropylene fiber

Standard: IEC 60228; IEC 60502;IEC 60840; IEC 62067

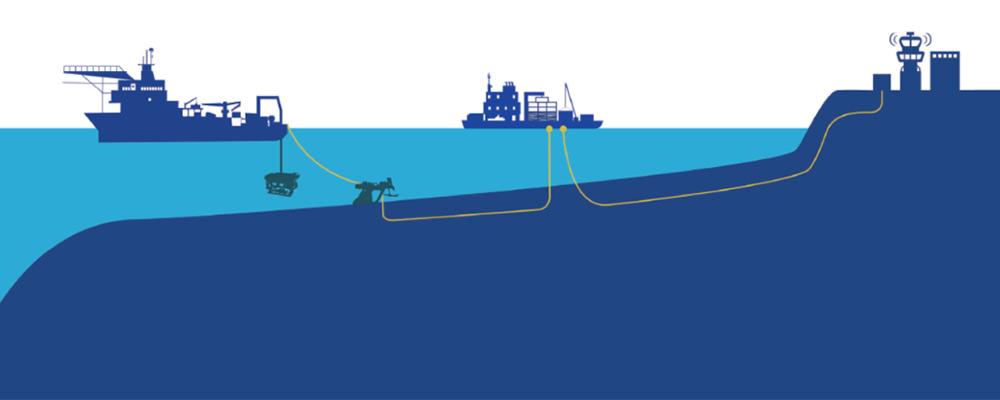

Laying and Installation of Submarine Cables

- After arrival at the site the cable should be examined visually to check any exterior damage.

- At site the cable drum should be rolled only in the direction shown on the flange otherwise the cable may become loose & hence difficult to handle.

- The route of the cable should be decided before hand considering the points like transportation of the cable at these points, atmosphere and ground conditions, where joints and terminations will be done, etc.

- While laying up the cable minimum bending radius as required to be strictly maintained.

- If the cable is pulled by pulling eye or winch, utmost care should be taken that tensile stress on the cable is within its limit.

- If the cable is laid in duct or pipe, outer diameter of the duct or pipe should be at least 1.5 times the diameter of the cable.

- Suitable derating factors should be applied as per the environmental & installation conditions while selecting the size of the cable.

- After laying up the cable system must be subject to the DC voltage as mentioned in the table no. 17. The system should be energized after it has withstood this test.

Reasons to Choose ZMS Cables

ZMS Qualification

ZMS has been qualified by the ISO 9001, OHSAS 18001, and ISO 14001 systems successfully. The whole quality assurance system covers the design and engineering, raw material selection, manufacturing, FAT, load out, and also the service for site testing and maintenance. The submarine power cable has been qualified by different kinds of Reports and certificates according to IEC, ICEA, and CIGRE standards: e.g. KEMA type test report, Type test report issued by SECRI in Shanghai, DNV, BV, SGS inspection report, etc.

Cable Customization

ZMS submarine cables are manufactured by GB, IEC, and other international standards and include a wide range of industry applications, but sometimes it is necessary to customize the cable or customize the cable solution according to the needs of the application. You can provide the specifications, cross section area, dimensions, materials, etc. of the undersea cable that needs to be customized. Our technical team can work with you to customize the cable to meet your specific application needs.

Experienced Manufacturer

ZMS can also offer cables with different sheathing, screening, taping & armoring options as per customer’s specific requirements. we can also offer cables suitable for superior fire performance characteristics as well as with low smoke & fume (LSF or LOSH/LOZH) properties. special features like longitudinal water sealing of conductors & cu screens, radial water sealing of cu screens as well as different colours of outer sheath can be provided on request.

About Submarine Communication Cables

The types of submarine communication cables can be simply divided into three aspects.

1. Structurally, they are mainly divided into three-core underground submarine cables and single-core underwater submarine cables. Most of the medium- and low-voltage lines use three-core submarine cables, and most of the high-voltage lines use single-core deep-sea cables.

2. Functionally, it is divided into submarine communication cables and submarine power cables. Submarine communication cables are mainly used for communication services, expensive, but have strong confidentiality. Submarine power cables are mainly used for high-power power transmission underwater, equivalent to underground power cables, but the application occasions and laying in different ways.

3. In terms of load type, they are divided into DC submarine cables and AC submarine cables. DC submarine cable is characterized by low-loss, easy-to-realize long-distance power transmission. However, the DC submarine cable application experience is not rich, DC converter station and other supporting construction costs are high. AC submarine cable loss is large, but the operation and maintenance technology is mature, supporting the construction cost is small. Therefore, submarine cable line designers usually need to weigh the technical and economic aspects to maximize the benefits.

Submarine Cable Catalog

ZMS SUBMARINE CABLE CATALOG VIEW

ZMS provides our partners around the world with brochures of our cable products, including aerial cables, submarine cables, control cables and other types of special cables, and more.

If you don’t know how to choose the product you need, or don’t find the cable type and size you need on this page, don’t worry. Contact us and send us your requirements, we can help you choose the right cable. You can provide us with the following information: cable voltage, conductor material, insulation and sheath material, shield type, armor type, etc. or you can provide us with cable installation environment, application requirements, etc. We will serve you wholeheartedly. ZMS cable supplier has a number of quality certifications: ISO 9000, ISO 9001, ISO14000, ISO14001, ISO18000, CE, IEC, BS, NFC, ASTM, DIN, etc.