15kv Mining Cable

Mining cables are flame retardant cables, usually also known as mining rubber sheathed flexible cables, suitable for frequency rated voltage U0/U 8.7/10KV and the following mining power plant mobile laying cable. Our mining power cables cover the entire range of applications. The cables are suitable for all voltage levels and electrical equipment installations in mines, mining equipment, and mining machinery.

ZMS Cable Group’s solutions cover the entire range from cable specification and design to complex international logistics. Efficient deliveries to all parts of the world are ensured with the fastest delivery times in the cable industry.

Mining Cable Types

Common types of mining rubberized cables include rubberized flexible cables, welding machine cables, submersible motor cables, radio equipment cables, and photographic light source cables. Customers can choose according to the mine, high and low voltage, and other factors. Due to the difficulty of power supply in the mining area and the poor environmental conditions, the selection of cables is a very important part, which will directly affect the operation and safety of the power supply.

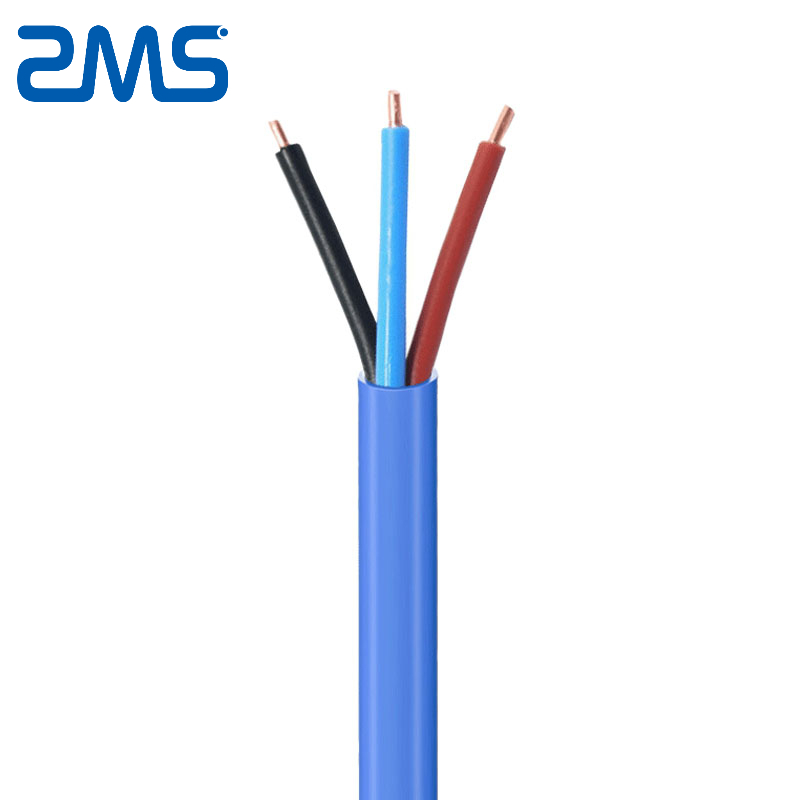

MKVV Mining Control Cable

MKVV PVC insulated PVC sheathed control mining cable.

Product Model Specifications: MKVV32, MKVV30 0.5-10mm2,7-61 core MKVVR 0.5-6mm2,2-61 core MKVVRP 0.5-4mm2,2-61 core MKVVP22, MKVVP2-22 1.5-10mm2,4-61 core MKVVP2-22-1 1.5-10mm2,4-61 core. 61 core.

Scope of application: Mainly used in 500KV substations and power plants power distribution equipment and strong electromagnetic field interference areas.

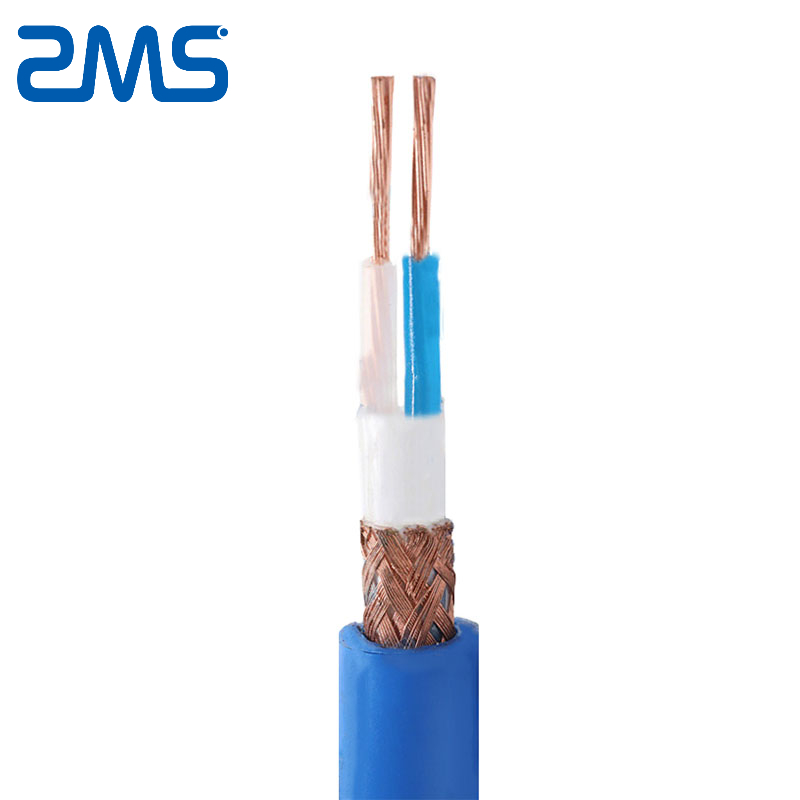

MHYVP Mining Shielded Indoor Communication Cable

MHYVP Mining Communication Cable Introduction:

Specification (5-10)*2*(0.75-1.5) polyethylene insulated braided shielded PVC sheathed communication cable for coal mine, used for signal transmission in places with large electric field interference, suitable for fixed laying.

MHYA32 Mining Outdoor Steel Wire Armored Communication Cable

MHYA32 Mining Communication Cable, coal mine polyethylene insulated aluminum polyethylene bonded layer steel wire armored polyvinyl chloride sheathed mining communication cable for vertical and inclined shafts.

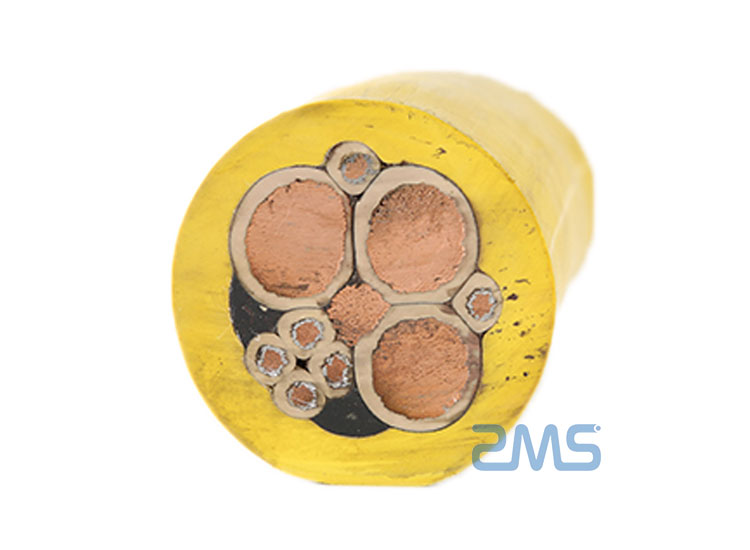

Shielded Rubber Flexible Mining Power Supply Cable

Executive standard: MT818-2009

Conductor material: tinned copper conductor

Conductor wire diameter: 0.39mm

Insulation: Flame-retardant and explosion-proof rubber

Sheath: high-density flame retardant explosion-proof rubber

Rated voltage: 0.38/0.66kv, 0.66/1.14kv, 1.9/3.3kv

Sheath color: yellow, black

Number of cores: 3+1+1 cores or multi-core

Cross-section range: 4~185 square mm

0.38/0.66KV Mobile Rubber Flexible Cable

Implementation standard: MT818-2009

Conductor material: pure copper

Conductor wire diameter: 0.39 mm

Insulation: Flame-retardant explosion-proof rubber

Sheath: high-density flame retardant explosion-proof rubber

Rated voltage: 0.38/0.66kv

Sheath color: black

Number of cores: 1 core or 4 cores

Cross-sectional range: 4~185 square mm

Scope of use: power connection for various underground mobile equipment

8.7/10KV Mobile Metal Shielded Rubber Flexible Cable

Execution standard: MT818-2009

Conductor material: tinned copper conductor

Conductor wire diameter: 0.39mm

Insulation: Flame-retardant explosion-proof rubber

Sheath: high-density flame retardant explosion-proof rubber

Rated voltage: 8.7/10KV, 6/10KV, 3.6/6KV

Sheath color: red

Number of cores: 3 cores

Cross-sectional range: 16~185 square mm

Scope of use: power connection for various underground mining equipment

The Choice of Mining Cable Cross-Section

We can customize suitable cable products according to customers’ cable cross-section requirements. The choice of mining cable cross-section includes the choice of high-voltage cable cross-section and low-voltage cable cross-section, and the choice of low-voltage cable cross-section is the main one.

Selection of the main core of the cable

Generally, the low-voltage power supply lines in mining areas are relatively long, and the cables will generate voltage drop and heat up when the current flow is in operation. To ensure the normal operation of the cable and motor, the following principles should be observed when selecting the cable cross-section.

1. The actual temperature rise of the cable during normal operation should not exceed the maximum temperature rise allowed by the insulation.

2. Select the cable line according to its allowable voltage loss during operation.

3. The cable cross-section should be selected to meet the requirements of mechanical strength.

Underground mining cables are wire and cable products for surface equipment and underground equipment used in the mining industry.

These include cables for mining machines, transporters, communication, lighting, and signaling equipment as well as electric drill cables, cap lamp wires, and power cables for underground mobile substations.

If you don’t know how to choose the product you need, or don’t find the cable type and size you need on this page, don’t worry. Contact us and send us your requirements, we can help you choose the right cable. You can provide us with the following information: cable voltage, conductor material, insulation and sheath material, shield type, armor type, etc. or you can provide us with cable installation environment, application requirements, etc. We will serve you wholeheartedly. ZMS cable supplier has a number of quality certifications: ISO 9000, ISO 9001, ISO14000, ISO14001, ISO18000, CE, IEC, BS, NFC, ASTM, DIN, etc.

What are the Considerations for Mining Industry Cable?

1. Safety

Safety must be considered when laying the cable line because the special environment of the mining area will make the laying of the line more complicated and easily affected by external forces leading to breakage. From such a perspective, we must pay attention to the safety of the line laying, in the design of the line, we must avoid cross-over with underground facilities, to avoid the construction of the project underway, to avoid a corrosive environment, etc.

2. Economic cost

The economic cost must be taken into account when laying the cable line because the cable line will be used in the mine, so the cost of construction is very high, so we must consider the economic cost of investment. When designing the line, it should not be too long, otherwise, the installation cost is high and the maintenance cost is also high afterward, while a shorter design can effectively control the economic cost of investment, based on this and then make long-term planning as much as possible.

3. Convenience

When laying cable lines must take into account the convenience of construction and maintenance, because the construction of inconvenience will consume more manpower and financial resources, and maintenance is not easy to affect the safety issues. In the selection of lines, we must consider the future use, not just the current environment, such as away from underground facilities will be conducive to the maintenance of the back.

Service of ZMS Cable Company

Over Productions Service: ZMS has a wide range of cable and conductor products for you to choose from. We will provide caring services and professional project solutions for everyone who needs them.

Quality Certification Services: ZMS cable products are manufactured according to GB, IEC, BS, NFC, ASTM, DIN, and other international standards. Our technical team can customize cable products that meet your requirements according to your needs.

Profession Customer Service: ZMS provides free professional consulting services to provide you with one-stop project solution services and rapid product delivery solutions.

Delivery And Shipping Services: While we at ZMS provide high-quality cables, we also provide good delivery solutions. While ensuring the safe delivery of products, we provide the best packaging and transportation solutions, greatly reducing customers’ transportation costs.

Packaging of ZMS: ZMS cable packaging is provided in the form of wooden reels, corrugated boxes, and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.