IEC60502 Standard Cable

IEC60502 standard cables are designed for power distribution from 1.8/3 KV to 18/30 KV at 50 Hz and are mainly used for cable installations in power stations, indoor conduits, outdoor, underground and submarine waters, as well as in industrial, distribution and power stations.

ZMS has absolutely thirty years of experience in the production of cables according to IEC standards. Our popular standards 60502, 60228, 60332, etc. have withstood both customer and test validation with high pass rates. Please feel free to contact us.

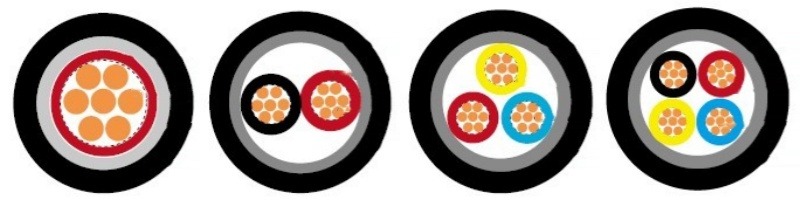

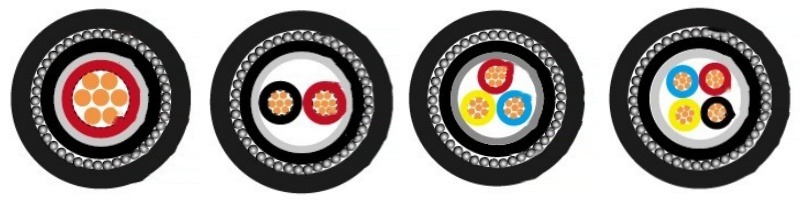

IEC 60502 Cable Main Types

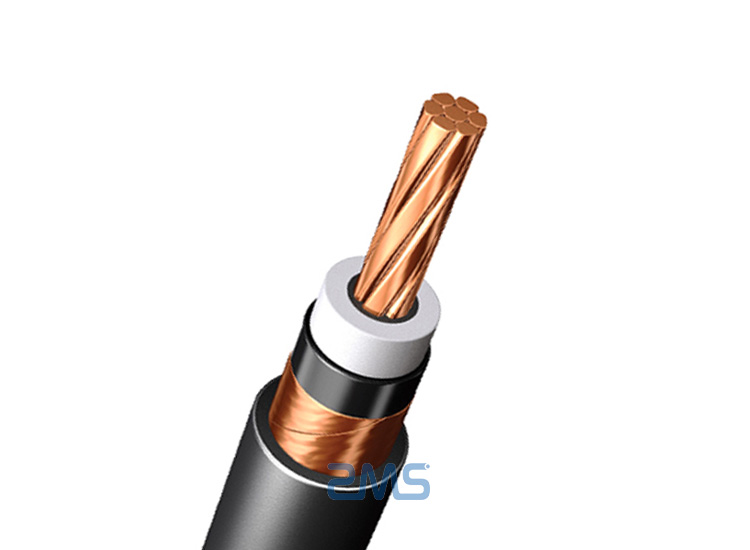

Single Core IEC60502 Insulated Cables

Conductor: Plain annealed copper or aluminum conductors conforming to IEC 60228 Category 1, Class 2.

Conductor shield: A conductor shield consists of a non-metallic, semiconductor composite extruded layer firmly bonded to the insulation layer, excluding all gaps. Conductor shielding is not required for PVC, EPR/HEPR insulated cables in the 1.8/3KV to 3.6/6KV range.

Insulation: PVC is generally used for 1.8/3KV and 3.6/6KV cable range, but XLPE, EPR/HEPR insulation can also be used.

Operating temperature: up to 70°C (PVC insulation); up to 90°C (XLPE or EPR insulation)

Temperature range: -5°C ( PVC sheathing ); -20°C ( PE sheathing )

Short-circuit temperature (maximum duration in short-circuit not exceeding 5s): 140-160°C ( PVC sheath ), 250°C ( PE sheath )

Bending radius: 12 x OD.

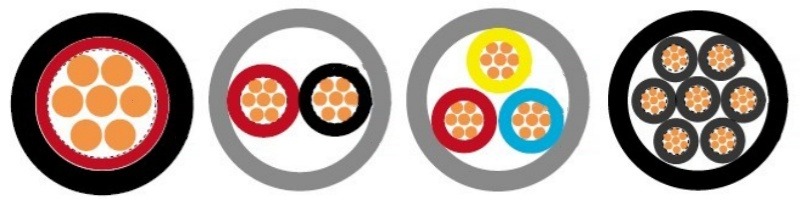

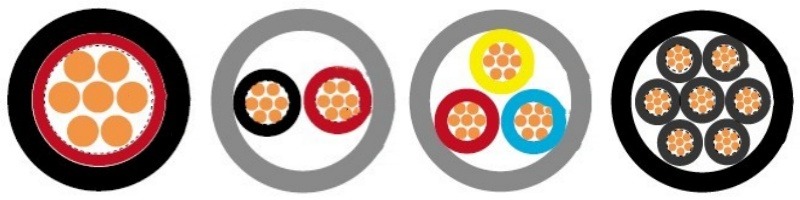

Three Core IEC60502 Insulated Cables

The three core IEC60502 insulated cables are designed to distribute electrical power with nominal voltage Uo/U ranging from 1.8/3KV to 26/35KV and frequency 50Hz. They are suitable for installation mostly in power supply stations, indoors and in cable ducts, outdoors, underground, and in water as well as for installation on cable trays for industries, switchboards, and power stations.

Conductor: Plain annealed copper or aluminum complying with IEC 60228 class 1 or 2.

Conductor Screen: The conductor screen consists of an extruded layer of nonmetallic,

semi-conducting compound applied on top of a semi-conducting tape.

Insulation: Insulation is of polyvinyl chloride (PVC) intended for 1.8/3.6KV and 3.6/6KV

cables, cross-linked polyethylene compound (XLPE), or ethylene propylene rubber (EPR/

HEPR).

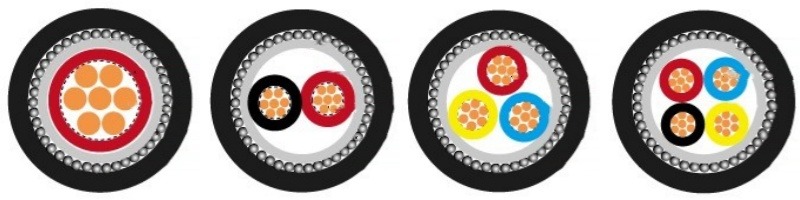

Armour (for armored cable): The armor is applied over the inner covering helically. It

consists of either flat galvanized steel wire armor (strip), round galvanized steel wire armor,

and double steel tape armor.

IEC60502 6KV 10KV 11KV High Voltage ABC Cable

Aerial Bundled Cable (ABC cable) has characteristics of power-transmitting and strong mechanical. In comparison with bare wire, aerial bundled cable (ABC cable) boasts many advantages, such as a small span in laying, higher safe reliability, and better atmosphere aging resistance property. Aerial bundled cable has the priority to be used in urban and rural power-transmitting construction projects.

The cable can be produced whose construction is phase conductors with neutral bare conductors or phase conductors with insulated neutral conductors. Aluminum (or Aluminum Alloy) stranded conductor (compacted), XLPE (or HDPE) insulated, AAC messenger core (AAAC or ACSR or Galvanized steel wire messenger core, bare or covered), Twisted (or parallel) power cable. And we can still produce the cables according to the request of customers.

ZMS About IEC60502 Standard List

IEC 60502-1 PVC Insulated Cables Unarmored

IEC 60502-1 PVC Insulated Cable Armor

IEC 60502-1 XLPE Insulated Cables Unarmored

IEC 60502-1 XLPE Insulated Cable Armor

IEC 60502-1 XLPE Insulated Lead Sheathed Cables Unarmored

IEC 60502-1 XLPE Insulated Lead Sheathed Cable Armor

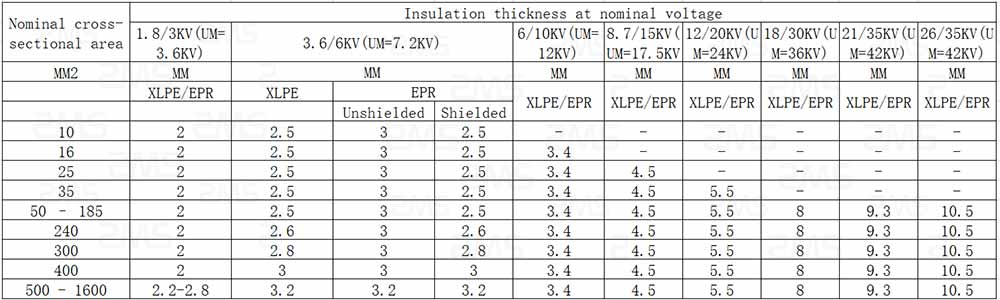

Insulation Thickness at Nominal Voltage

Insulation Shield

Extruded semi-conductive cross-linked composite layers are applied to the insulating outer layer. The semiconductor extrusion layer should include a bonded, or peelable semiconductor composite layer, with the ability to be soldered or terminated for removal.

As an option, a semi-conductive tape can be applied to the extruded semi-conductive metal layer as a mat layer. With a minimum thickness of 0.3 mm and a maximum resistivity of 500 ohms at 90°C, the meter shield is tightly mounted on the insulation excluding all air voids, and can be easily peeled off by hand in the field.

The insulation shield is not necessary for cables with PVC, EPR/HEPR insulation in the range of 1.8/3KV to 3.6/6KV. The shield can be wrapped around the perimeter of the semiconductor waterproofing layer to achieve longitudinal waterproofing.

Inner Sheath

Separate sheathing (armored cable): Separate sheathing consists of an extruded layer of PVC, PE, or LSZH with a thickness of 0.02Du+0.6mm, Du being a calculated diameter based on technical parameters such as sheathing. The general thickness of the breakaway sheath is more than 1.2mm. the breakaway sheath is generally applied to the outer layer of the lead sheath, the thickness of the common breakaway sheath is less than 1.0mm.

Wrap-around mat layer (lead sheath armored cable): The wrap-around mat layer mainly consists of an impregnated/synthetic paper tape, or it can be a composite of two layers, and this tape consists of a special conforming material. The thickness is mainly around 1.5mm.

Armor layer (for armored cable): The armor layer is mostly round steel wire armor, which is applied to the outer layer of the separated sheath.

Outer Sheath

The outer sheath extrusion layer contains either an extruded thermoplastic compound (PEV, PE, or LSZH are available) or an elastomeric compound (polychloroprene CSP or chlorosulfonated polyethylene).

The typical sheath thickness is 0.035+D, D being the diameter of the sheath in millimeters.

The outer sheath thickness should be less than 1.4mm for non-armor cable and non-armor total sheath cable, metal layer shield, or concentric conductor, and more than 1.8mm for concentric conductor total sheath metal armor cable.

Service of ZMS Company

Over Productions Service: ZMS has a wide range of cable and conductor products for you to choose from. We will provide caring services and professional project solutions for everyone who needs them.

Quality Certification Services: ZMS cable products are manufactured according to GB, IEC, BS, NFC, ASTM, DIN, and other international standards. Our technical team can customize cable products that meet your requirements according to your needs.

Profession Customer Service: ZMS provides free professional consulting services to provide you with one-stop project solution services and rapid product delivery solutions.

Delivery And Shipping Services: While we at ZMS provide high-quality cables, we also provide good delivery solutions. While ensuring the safe delivery of products, we provide the best packaging and transportation solutions, greatly reducing customers’ transportation costs.

Packaging of ZMS: ZMS cable packaging is provided in the form of wooden reels, corrugated boxes, and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.