Voltage Cable

Voltage Cables are cables that cable manufacturers and producers have graded for different voltages, such as low-voltage, medium-voltage, high-voltage, and even ultra-high-voltage cables. These cables have always been within the production range of the ZMS cable factory and have thirty years of skillful production experience. We welcome inquiries from customers all over the world.

Cable Voltage Rating Table

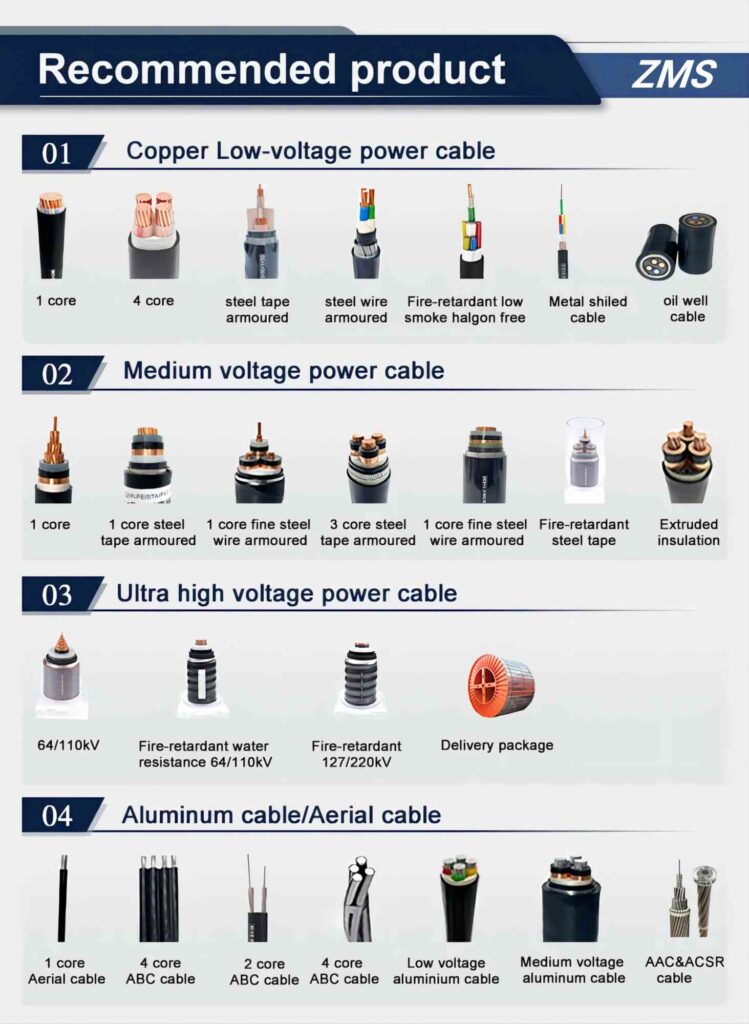

ZMS cable manufacturer can produce cable products with voltage levels of 0.6/1, 1/1, 3.6/6, 6/6, 6/10, 8.7/10, 8.7/15, 12/15, 12/20, 18/20, 18/30, 21/35, 26/35, 36/63, 48/63, 64/110, 127/220, 190/30, 290/500KV A total of 19 types. ZMS cable voltage level division is mainly the following:

- Safety voltage (usually 36V or less)

- Low voltage (also divided into 220V and 380V, residential single-phase power users generally use 220V)

- Medium and high volt tage(6kV, 10kV, 35kV, 220kV)

- Ultra-high voltage(330kV,500kV,750kV)

- Extra-high voltage 1000KV (AC),± 800KV(DC) and above

(Note: The value before the slash is the phase voltage value and the value after the slash is the line voltage value.)

Description of ZMS Voltage Cable

ZMS electric cable company is a well-known manufacturer of Cables of different voltage levels. No matter what voltage level or type of cable you need, we can provide a customized cable solution based on your application needs.

ZMS has rich cooperation and project experience in manufacturing low voltage cables, we can customize the cables according to customer’s needs, and the advantage is to save project costs and unnecessary trouble.

Types: blow 1kv, YJV, ZR-VV, NH-VV, WD-YJY, etc.

For medium voltage cables, ZMS has delivered satisfactory answers in cooperation with projects in South Africa, Iceland, Thailand, etc. Our medium voltage cables comply with a variety of qualifications, are delivered on time, and are highly secure.

Types: 3.6KV~35KV, YJV, VV, YJLV, VLV, etc.

High-voltage cables are divided into overhead high-voltage cables and underground high-voltage cables.ZMS can be customized according to customer’s demand, the main thing is good quality and low price, looking forward to cooperating with you.

Types: 10KV-35KV, ZR—YJV22—3×50(70, 95, 120, 150), etc. ZR—YJV62—300(400).

In addition to this, there are special-purpose cables, such as overhead insulated cables and mining cables, which have different voltage ratings.

About ZMS Voltage Level Series

Over Productions Service: ZMS has a wide range of cable and conductor products for you to choose from. We will provide caring services and professional project solutions for everyone who needs them.

Quality Certification Services: ZMS cable products are manufactured according to GB, IEC, BS, NFC, ASTM, DIN, and other international standards. Our technical team can customize cable products that meet your requirements according to your needs.

Profession Customer Service: ZMS provides free professional consulting services to provide you with one-stop project solution services and rapid product delivery solutions.

Delivery And Shipping Services: While we at ZMS provide high-quality cables, we also provide good delivery solutions. While ensuring the safe delivery of products, we provide the best packaging and transportation solutions, greatly reducing customers’ transportation costs.

Packaging of ZMS: ZMS cable packaging is provided in the form of wooden reels, corrugated boxes, and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.

About Cable Voltage Level

Cable rated voltage refers to the maximum voltage value that the cable can withstand under normal conditions of use. It is an important parameter for cable design and selection, which directly affects the service life and safety performance of the cable. Cable rated voltage is based on international standards and national standards, different types of cables have different rated voltages.

All voltage cables have different structural elements, they have different combinations of one or more conductors, insulation materials, sheaths, and armors. High-voltage cables and low-voltage cables differ in that they have an additional inner layer in the insulation jacket to control the electric field around the conductor. The shielding layer of the conductor can surround each insulated conductor, which can balance the stress on the cable insulation layer, prevent it from interfering with external equipment, and prevent external electric or magnetic fields from entering the cable.

Factors Affecting the Rated Voltage of Cables

- Insulation Material: The rated voltage of the cable has a great relationship with the performance of the insulation material. Generally speaking, the higher the voltage resistance level of the insulating material, the higher the rated voltage of the cable.

- Overall Structure: The construction form and number of layers of the cable will also affect its rated voltage. The overall structure of the complex cable and its rated voltage will usually be lower than the simple structure of the cable.

- Environmental Conditions: The environmental conditions in which the cable is located, such as temperature, humidity, altitude, etc., will also affect its rated voltage. For example, cables used in higher altitude environments will have a relatively lower rated voltage.

In short, the correct choice of cable-rated voltage is to protect the operation of power equipment safely and the normal service life of the key.

ZMS Cable Factory

ZMS CABLE is very experienced in manufacturing and closing cases for voltage cables, and we have customers all over the world. ZMS has its cable factory and accurate and strict qualification certificate for cable products.

If you don’t know how to choose the cable products you need or can’t find the cable type and size you need on this page, don’t worry. Contact us and send us your requirements, and we can help you choose the right cable. You can provide us with the following information: cable voltage, conductor material, insulation and sheath material, shield type, armor type, etc. or you can provide us with cable installation environment, application requirements, etc. We will serve you wholeheartedly. ZMS Cable Supplier has some quality certifications: ISO 9000, ISO 9001, ISO14000, ISO14001, ISO18000, CE, IEC, BS, NFC, ASTM, DIN, etc.