AAC AAAC ACSR

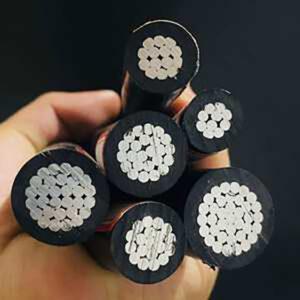

AAC, AAAC, and ACSR Bare Conductors are used as overhead power lines, transmission lines, and distribution lines. An aluminum bare conductor is a wire without an insulating layer on the outside of the conductor. Different conductor materials are suitable for different span lengths and the ability to withstand breaking strength. All aluminum conductors consist of one or more bundles of aluminum wire, depending on the specific application environment of the product. Due to the natural corrosion resistance of the all-aluminum structure, it is also popular in coastal areas.

AAC AAAC ACSR

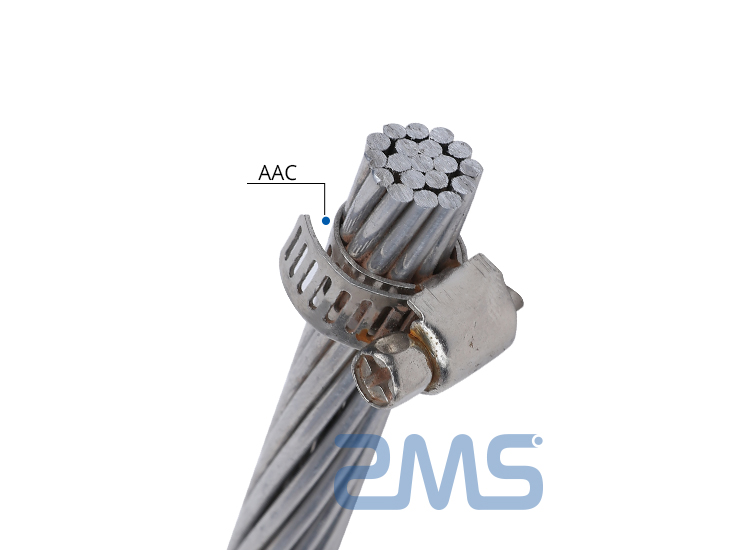

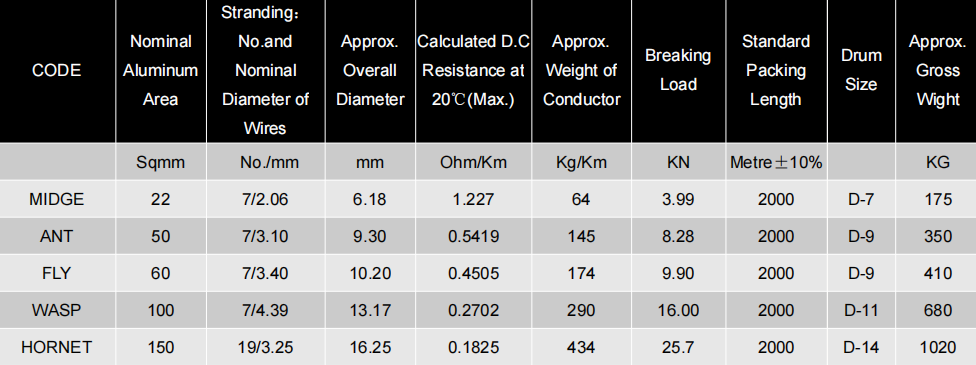

AAC - All Aluminum Conductor

Hard Drawn Aluminum Type AL1

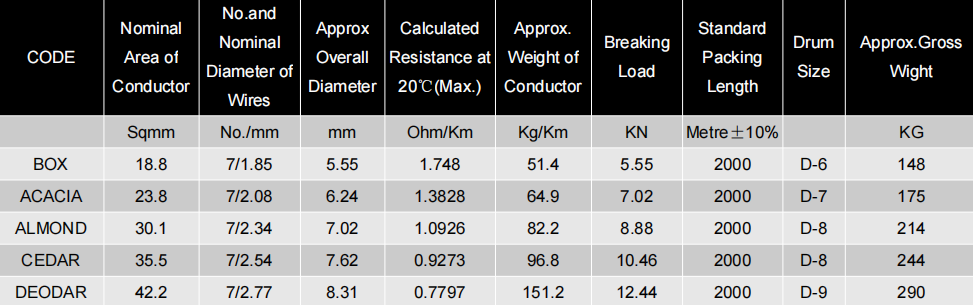

AAAC - All Aluminum Alloy Conductor

Aluminum alloy conductor Type AL2 to AL7

ACSR - Aluminum Conductor Steel Reinforced

Hard Drawn Aluminum, AL1 and Zinc Coated Steel Wire

Description of Bare Conductor

Overhead lines are high voltage transmission line bare conductors above the ground level, supported by pylons and poles. ZMS aluminum alloy conductor overhead power lines have a series of advantages such as strong load and overload capacity, good heat resistance, large transmission capacity, and high tensile strength. At the same time, it can also greatly reduce the investment in line construction, effectively improve the urban environment, and is widely used in urban and rural power grid reconstruction.

AAC Conductor is a refined aluminium-stranded conductor with a minimum metal purity of 99.7%. It is mainly used in urban areas with short distances and close supports. Its characteristics are good corrosion resistance and can be used near the coast. The AAC (all aluminum conductor) wire is the most economical bare overhead conductor due to its lighter weight.

Conductor

Hard-drawn aluminum conductor as per EN 60889 Type AL1 according to BS 215.

Standards / Testing Specifications

IEC 61089, BS 215 part 1, DIN 48201 part 5, ASTM B231, BS EN50182, GB/T 1179-2008, or by our customer’s requirement.

Compared with AAC and ACSR, AAAC conductor is mainly used as bare overhead transmission cables and as primary and secondary distribution cables. It has better strength and weight, better electrical properties, better vertical tensile properties, and better corrosion resistance. These characteristics make AAAC widely recognized and loved by more people in power distribution and medium and high voltage transmission lines.

Conductor

AAAC conductor is made of from aluminum-magnesium-silicon alloy of high electrical conductivity (min 53% IACS) containing magnesium (0.6-0.9%) & silicon (0.5-0.9%) to give it better mechanical properties after treatment. AAAC conductors are made out of aluminum alloy 6201.

Standards / Testing Specifications

IEC 61089, BS EN 50182, BS 215 part2, ASTM B232, DIN 48204, GB/T 1179-2008, and customer’s required standards.

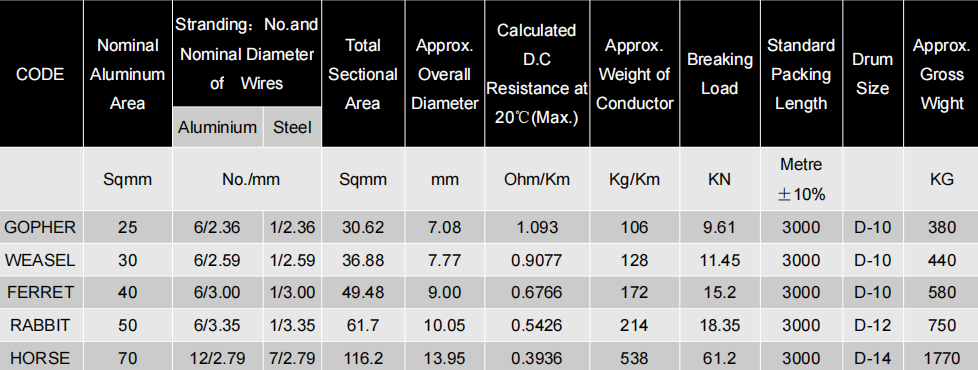

ACSR is a high-voltage transmission cable used in grid applications. ACSR has a wide range of applications. Suitable for transmission lines of various voltage levels. Can also be laid in rivers, canyons, and places with special geographical features. ACSR bare conductors have been widely used in power transmission lines with various voltage levels because they have such good characteristics as structure, convenient installation and maintenance, and low-cost large transmission capacity. They are also suitable for laying across rivers valleys and places where special geographical features exist.

Conductor

The structure of ACSR is simple. It consists of a solid or stranded steel core surrounded by strands of aluminum. Aluminum 1350-H-19 wires, concentrically stranded on a steel core. The core wire for ACSR is available with class A, B, or C galvanizing.

Standard

ASTM — B 230, ASTM — B 231, TS IEC 1089, DIN48201, BS 215.

Production & Installation

AAC Wire

AAC conductors can be installed in air.It is recommended that the installation instructions indicated by the Local Electric Code,or any equivalent, be followed, so that the safeguarding of persons and the integrity of the product will not be affected by deficiencies in the installation.

AAAC

AAAC cable can be installed in air. It is recommended that the installation instructions indicated by the Local Electric Code,or any equivalent, be followed, so that the safeguarding of persons and the integrity of the product will not be affected by deficiencies in the installation.

ACSR Conductor

It is recommended that the installation instructions indicated by the Local Electric Code, or any equivalent, be followed, so that the safeguarding of persons and the integrity of the product will not be affected by deficiencies in the installation.

Bare Conductor Catalog

ZMS OVERHEAD LINE PDF

ZMS provides our partners around the world with brochures of our cable products, including aerial cables, submarine cables, control cables and other types of special cables, and more.

ZMS CABLE is very experienced in manufacturing and closing cases for bare overhead conductors, and we have customers all over the world. ZMS has its cable factory and accurate and strict qualification certificate for cable products.

If you don’t know how to choose the cable products you need or can’t find the cable type and size you need on this page, don’t worry. Contact us and send us your requirements, and we can help you choose the right cable. You can provide us with the following information: cable voltage, conductor material, insulation and sheath material, shield type, armor type, etc. or you can provide us with cable installation environment, application requirements, etc. We will serve you wholeheartedly. ZMS Cable Supplier has some quality certifications: ISO 9000, ISO 9001, ISO14000, ISO14001, ISO18000, CE, IEC, BS, NFC, ASTM, DIN, etc.

ZMS Company Service

Over Productions Service: ZMS has a wide range of cable and conductor products for you to choose from. We will provide caring services and professional project solutions for everyone who needs them.

Quality Certification Services: ZMS cable products are manufactured according to GB, IEC, BS, NFC, ASTM, DIN, and other international standards. Our technical team can customize cable products that meet your requirements according to your needs.

Profession Customer Service: ZMS provides free professional consulting services to provide you with one-stop project solution services and rapid product delivery solutions.

Delivery And Shipping Services: While we at ZMS provide high-quality cables, we also provide good delivery solutions. While ensuring the safe delivery of products, we provide the best packaging and transportation solutions, greatly reducing customers’ transportation costs.

Packaging of ZMS: ZMS cable packaging is provided in the form of wooden reels, corrugated boxes, and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.

More Information