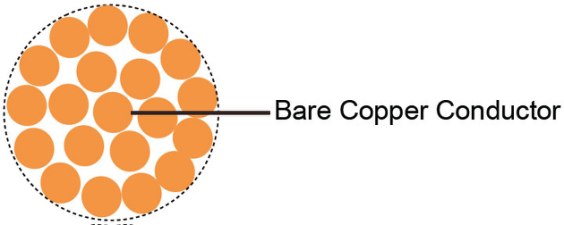

Bare Copper Conductor

ZMS manufactures a range of bare copper conductors suitable for use in electrical earthing systems and insulators for overhead line transmission and other power distribution equipment. It conforms to BS EN 60228 or IEC 60228 industry standards. It is classified as Category 2 stranded bare copper wire following BS6360/81, uninsulated, unjacketed, soft drawn copper wire, which offers greater flexibility than solid hard drawn wire.

Copper is also naturally resistant to environmental stresses such as moisture, corrosive environments, and salt-laden climates.

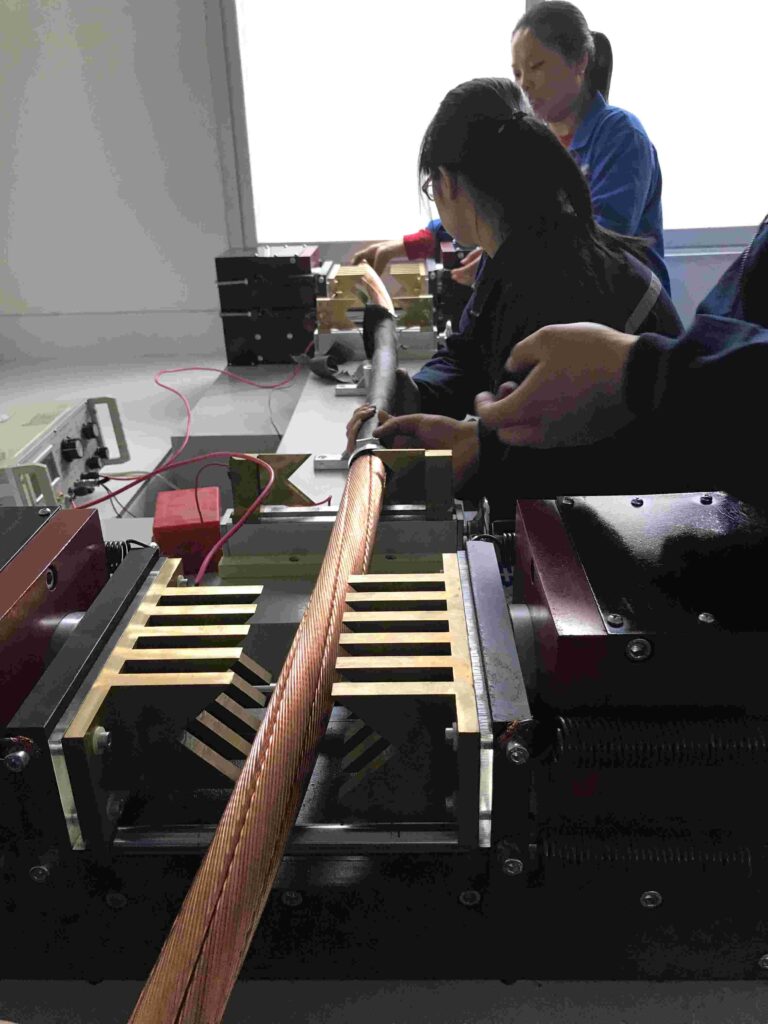

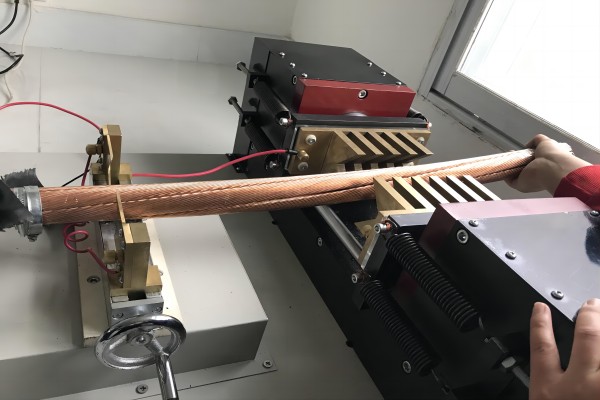

ZMS Manufacturing Process

Conductor: Conductor Grade 2 annealed stranded copper

ZMS requires a very large number of material categories and varieties in the manufacture of bare stranded copper conductors and has particularly high-performance requirements. For example, the conductor material used conductor 2 annealed stranded copper, the requirements of the exclusive bare copper conductor oxygen-free copper in the copper content of > 99.97%, the low-oxygen copper copper copper content of > 99.95%. At the same time, the choice of materials will play a decisive role in the manufacturing process, product performance, and service life.

Human Monitoring

Copper Stranding Process

Cross-Sectional Testing

Both solid and stranded bare copper conductors are available in hard, medium-hard, or soft states. The stranded conductors are concentrically stranded in the hard and medium-hard states and unlay stranded in a combination of soft drawn states.

The technical engineers of the ZMS cable factory have extensive experience in selecting the optimum bare copper conductor for the application or cross sectional area. We deliver on time and offer innovative logistics solutions to help improve supply chain efficiency. Be sure to contact us to discuss your specific needs.

Bare Copper Conductor Applications

ZMS offers bare copper conductors primarily for use in energy transfer devices to maximize thermal and electrical conductivity and to transfer energy with optimum efficiency. The uninsulated bare cooper wire can be used as an grounding wire, and stranded bare soft copper conductors or annealed copper conductors are recommended for use as neutral conductors in circuit earthing connections as well as in machinery and equipment earthing systems. Alternatively, soft copper can be used for transformer lead wires or other tension-free connection jumpers.

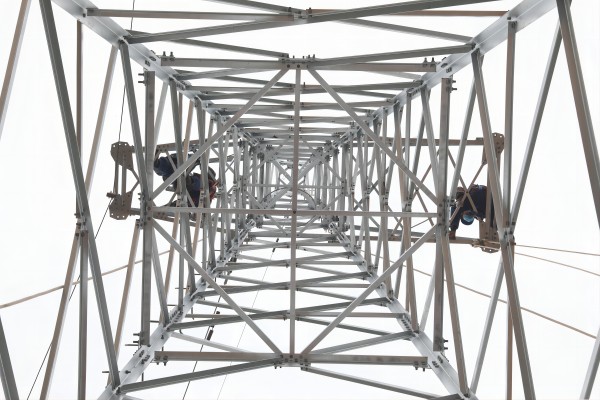

Ground Line Transmission

Overhead Line Transmission

Other Industrial Transmission

Solid and stranded (Class AA and A) bare copper is suitable for overhead transmission and distribution applications. Stranded conductors (Class B and C) for greater flexibility are used for uninsulated connections, jumpers and grounding in electrical structures. Soft drawn copper is a single layer construction.

Characteristics of Bare Copper Conductors

1. Less Susceptible to Corrosion: Stranded bare soft copper or annealed copper conductors are suitable for direct burial and do not suffer from the corrosion problems inherent in aluminum conductors.

2. High Electrical Conductivity: Copper’s conductivity is almost twice that of aluminum, giving it an even greater advantage in transmission performance. Copper is much easier to terminate and connect at joints and splices than aluminum.

3. Stable Signal Transmission: Bare copper wire is commonly used for processing pure copper conductors, but when used for shielding it is the best conductor other than gold shielding.

4. Price Advantage: Bare copper cable is cheaper than tinned, nickel-plated, and silver-plated copper, so if you choose ZMS in terms of price, you will be half successful.

5. Better Tinned: Tinning prevents the copper from being oxidized by exposure to air to form a film, copper green, which is conductive and increases resistance.

ZMS Production Standards and Specifications

Our bare copper conductor meets or exceeds the following ASTM Specifications:

- B-1 Hard-Drawn Copper Wire.

- B-2 Medium-Hard Copper Wire.

- B-3 Soft or Annealed Copper Wire.

- B-8 Concentric-Lay-Stranded Hard, Medium-Hard, or Soft Copper Conductor.

- B-33 Tinned Conductors

- B-787 19 Wire Combination Unilay-Stranded Soft copper wire.

Installation: Soft drawn copper conductor can be installed in air.

Nominal | Number & | Overall | Maximum | Allowable | Cable | Standard |

mm² | No. /mm | mm | /km | A | kg/km | m |

10 | 7/1.35 | 4.05 | 1.83 | 90 | 90 | 1000/R |

16 | 7/1.70 | 5.10 | 1.15 | 125 | 143 | 1000/R |

25 | 7/2.14 | 6.42 | 0.727 | 160 | 227 | 1000/R |

35 | 19/1.53 | 7.65 | 0.524 | 200 | 314 | 1000/R |

50 | 19/1.79 | 8.90 | 0.387 | 250 | 428 | 1000/R |

70 | 19/2.14 | 10.70 | 0.268 | 310 | 618 | 1000/R |

95 | 19/2.52 | 12.60 | 0.193 | 380 | 858 | 1000/R |

120 | 37/2.03 | 14.21 | 0.153 | 440 | 1097 | 1000/R |

150 | 37/2.25 | 15.75 | 0.124 | 510 | 1334 | 1000/R |

185 | 37/2.52 | 17.64 | 0.0991 | 585 | 1673 | 1000/R |

240 | 61/2.25 | 20.25 | 0.0754 | 700 | 2200 | 1000/R |

300 | 61/2.52 | 22.68 | 0.0601 | 800 | 2760 | 1000/R |

400 | 61/2.85 | 25.65 | 0.0470 | 900 | 3350 | 1000/R |

500 | 61/3.20 | 28.80 | 0.0366 | 1110 | 4451 | 1000/R |

ZMS Cable Service

Over Productions Service: ZMS has a wide range of cable and conductor products for you to choose from. We will provide caring services and professional project solutions for everyone who needs them.

Quality Certification Services: ZMS cable products are manufactured according to GB, IEC, BS, NFC, ASTM, DIN, and other international standards. Our technical team can customize cable products that meet your requirements according to your needs.

Profession Customer Service: ZMS provides free professional consulting services to provide you with one-stop project solution services and rapid product delivery solutions.

Delivery And Shipping Services: While we at ZMS provide high-quality cables, we also provide good delivery solutions. While ensuring the safe delivery of products, we provide the best packaging and transportation solutions, greatly reducing customers’ transportation costs.

Packaging of ZMS: ZMS cable packaging is provided in the form of wooden reels, corrugated boxes, and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.