Offshore & Marine Cables

Offshore & Marine Cable is a kind of wire and cable used for power, lighting, control, and communication transmission of various ships in rivers and sea and offshore or marine buildings, including marine power cable, marine control cable, marine communication cable, and so on. Usually, the marine cable has limited laying space, so the armored structure adopts metal wire braiding, which is the biggest difference between the structure and the land-based ordinary power, control, and communication cables.

Due to the harsher environmental conditions, ZMS is required to produce cables that are safe, reliable, long life, small in size, lightweight, and have excellent temperature resistance, fire resistance, flame resistance, oil resistance, moisture resistance, seawater resistance, excellent electrical and mechanical properties and other requirements.

Types of Marine Cables

Marine Wires can be divided into marine power cables (including rated voltage frequency AC 1kV and the following low-voltage power cables and rated voltage frequency AC 3 ~ 15kV medium voltage power cables), marine control cables, marine communication cables, marine signal cables, and marine RF cables according to the scope of use.

Marine power cable: used for power transmission of various ships in rivers and sea and offshore or marine buildings.

Marine control cable: used for the control signal transmission of various ships in rivers and sea and offshore or marine buildings.

Marine communication cable: used for signal transmission and control systems in various propagation communication, electronic computer, and information processing equipment.

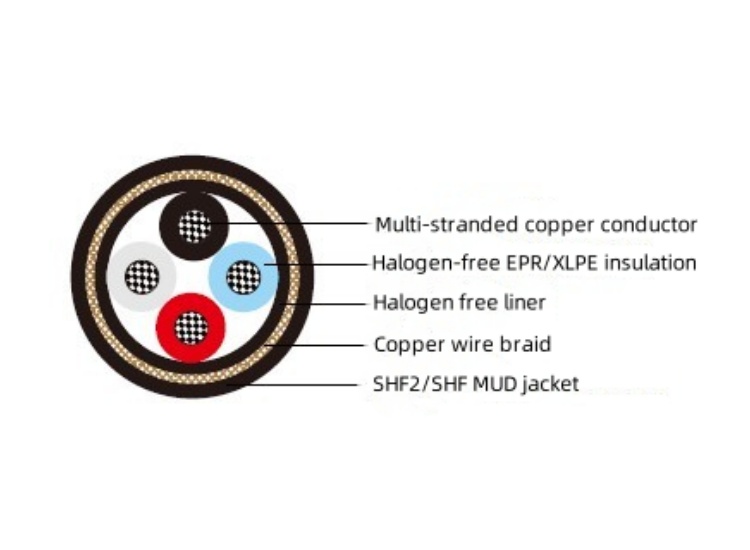

NEK606 Standard Offshore and Marine Cables

NEK606 standard offshore and marine cables are flame-retardant, low-smoke, halogen-free, and mud-resistant for control, power, and lighting systems.

Conductor: IEC 60228 class 2 multi-strand tinned annealed copper conductor.

Insulation: Halogen-free EPR. XLPE optional (for TFOU cables).

Backing layer: Halogen-free compound.

Armor: Tinned copper braid.

Sheath: Halogen-free thermosetting material SHF2 (for type P1); Halogen-free, mud-proof thermosetting material SHF MUD (for type P1/P8)

Standards: IEC 60092-353, IEC 60092-351, IEC 60092-359, IEC 60332-1, IEC 60332-3-22, IEC 60754-1,2, IEC 61034-1,2, NEK 606:2004

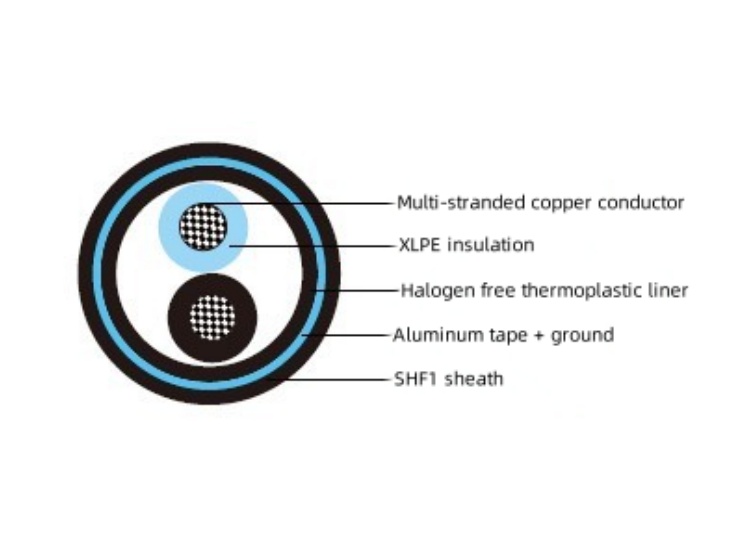

NEK606 Standard Instrumentation Cable

NEK606 standard offshore and marine cables are flame retardant low smoke and halogen-free and are suitable for use in living, accommodation, and office areas.

Conductor: IEC 60228 class 2 round multi-strand copper conductor.

Insulation: XLPE.

Backing layer: Halogen-free thermoplastic material

Metal shielding: longitudinal aluminum tape with a thickness of 0.2 mm, multi-stranded copper ground.

Sheath: Halogen-free thermoplastic material SHF1, gray.

Model: S2 or S2/S6 RFOU(c) 250V, P16 IFLI 250 V, S11 RU(i) 250 V, S12 RU(c) 250 V

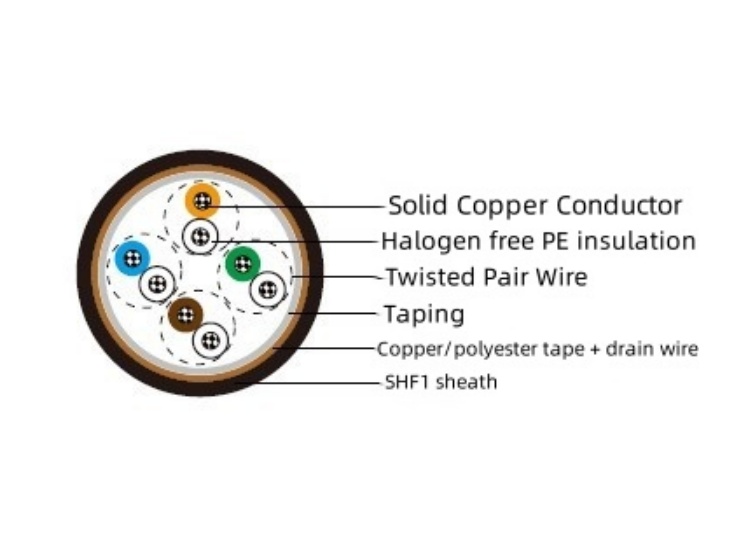

NEK606 Standard Communication Cables

The cable is flame retardant and low smoke and halogen free and is suitable for indoor communications within ships warships.

Conductor: 0.5mm solid tinned copper conductor.

Insulation: Halogen free thermoplastic PE.

Stranding: Colored cores twisted together. Pairs are stranded into cores or units of 10 pairs. Units are twisted into 20, 30, 50 pairs of cable. 2 pairs of cable are twisted in groups of four wires.

Winding tape: polyester tape.

Total shielding: the outer layer of the core is copper-plastic composite tape and a 0.5mm solid tinned copper drain wire.

Sheath: Halogen-free thermoplastic material SHF1, gray.

Standard: IEC 60092-359, IEC 60332-1, IEC 60332-3-22, IEC 60754-1,2, IEC 61034-1,2, NEK 606:2004

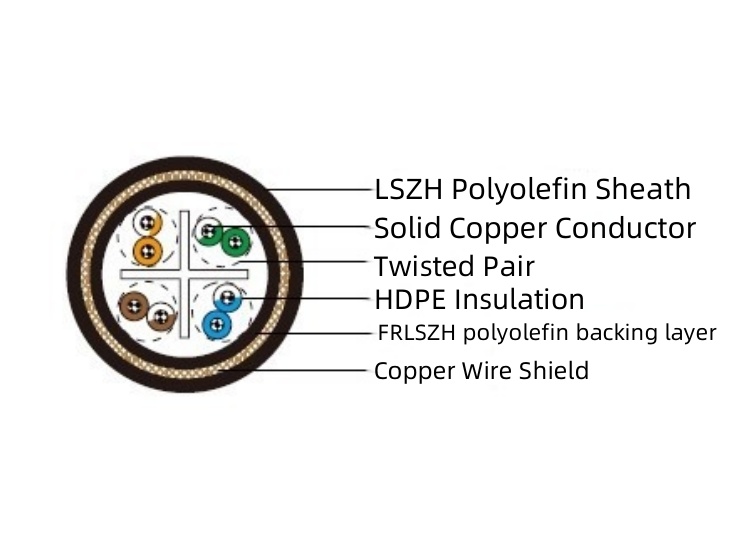

NEK606 Standard Data Cable

Cat6 is a standard for Ethernet and other network protocol cables for 10BaseT, 100BaseTx & 1000BaseT (Gigabit Ethernet) applications. The cable features a copper braid armor and a flame retardant, a mud-proof outer jacket that provides additional mechanical protection while maintaining the cable’s flexibility.

Conductor: 23AWG solid copper conductor.

Insulation: HDPE.

Stranding: Two colored insulated wires twisted together to make a pair.

Backing layer: Flame retardant low smoke halogen free polyolefin, black color.

Armor: 0.2/0.3mm copper wire braid.

Sheath: low-smoke halogen-free polyolefin.

Cat6 F/UTP: This cable has an aluminum/polyester ribbon overall shield and drain wire.

Cat6 SF/UTP: The cable has aluminum/polyester tape & copper braid double shield and drain wire.

Product Advantages

- ZMS marine cable has the advantages of reliable performance, long life, small size, lightweight, flame retardant, low smoke, halogen-free, etc. Marine power cables conform to IEC 60092 or can be customized according to customer requirements.

- ZMS boat cable and electrical marine wire may be customized upon request. Value-added services such as striping, twisting, special packaging, custom printing, cut & strip, dyeing, tinning, and barcoding may be performed on marine wire and cable. Can help you meet your specific requirements for electrical marine.

Cooperation with ZMS

ZMS has been gradually expanding its market for marine cables. In countries such as UAE, India, Malaysia, etc., our cables have been well received. In recent years, with the rapid development of global logistics, the export volume of ship cables has only increased.

Clients in Indonesia

Cooperated with an Indonesian customer on a marine cable project of more than 5,000 meters. The customer visited the cable factory to inspect the goods.

Clients In Vietnam

We cooperated with a Vietnamese customer on a marine instrument cable project of about 3000 meters, and the customer was very satisfied the quality of the product

Clients In Bangladesh

Cooperated with a Bangladeshi customer on a project of more than six thousand meters of marine control cables. The customer visited and expressed his satisfaction with the product.

Marine Cable Specifications Catalog

ZMS MARINE CABLE PDF

ZMS provides our partners around the world with brochures of our cable products, including aerial cables, submarine cables, control cables and other types of special cables, and more.

If you don’t know how to choose the product you need, or don’t find the cable type and size you need on this page, don’t worry. Contact us and send us your requirements, we can help you choose the right cable. You can provide us with the following information: cable voltage, conductor material, insulation and sheath material, shield type, armor type, etc. or you can provide us with cable installation environment, application requirements, etc. We will serve you wholeheartedly. ZMS cable supplier has a number of quality certifications: ISO 9000, ISO 9001, ISO14000, ISO14001, ISO18000, CE, IEC, BS, NFC, ASTM, DIN, etc.

The Use Requirements and Laying Conditions of Marine Cables

The Use Of Marine Cables And Laying Conditions

1. For power, lighting, and control cables in the river and sea vessels and floating buildings on the water. The working voltage is 500V AC or 1000V DC and below.

2. Flexible structure cable for connecting mobile electrical equipment, the rest are fixed for laying.

3. Steel wire braided cables are used in places susceptible to external damage. Copper braided cables are used in places where interference is prevented.

4. All cables can be used in places that require no delay

Requirements For The Use Of Marine Cables

1. The cable should apply to all places and various climatic conditions and can withstand the cold, dry, hot, and humid areas of various climatic conditions.

2. The ship is far away from land for a long time, so the safety and reliability of the cable are very high, such as good electrical performance, stability, and no delay. The cables laid in some compartments require good oil resistance.

3. Small space inside the ship, strict requirements for cable outer diameter and outer diameter tolerance. For easy installation, the cable is required to be soft. In certain compartments (such as the main engine, and boiler compartment), the temperature is as high as 45-55 ℃, with some high humidity of more than 95%, requiring the cable heat-resistant, moisture-proof, mold resistance good.

4. When the cable is installed or moved, the tension is generally greater than on land and susceptible to external forces such as scraping and rubbing, requiring good mechanical properties. The cable on the deck, mast requires resistance to sunlight, atmosphere, and seawater pouring corrosion.

5. Part of the cable requires the ability to prevent interference.

6. Marine wire and cable flame retardant, fire-resistant requirements are particularly strict.

Executive standard: GB9331.2-88

Use: This product is suitable for various river and sea vessels and offshore oil platforms and other water buildings to transmit electrical energy.

Use Characteristics

The long-term allowable working temperature of the cable is 85℃, and the rated voltage Uo/U is 0.6/1KV. When laying, the bending radius of the cable is as follows: metal shield armored type is 6 times the outer diameter of the cable. For the non-armored type, 4 times the cable outer diameter when the outer diameter is less than or equal to 25mm, 6 times the cable outer diameter when it is larger than 25mm.

Model name: CEFR/DA Ethylene propylene insulated neoprene sheathed marine power flexible cable, type DA, for connecting mobile electrical appliances.

Technical Requirements

1. It should be able to withstand 30,000 curve tests in one trip.

2. The cable should be able to withstand AC voltage 3500V or DC 8400V, 5min without breakdown.

3. The cable core structure, insulation resistance, insulation, and sheath thickness and weight shall conform to the provisions of GB9331.2-88.

Service of ZMS Company

Over Productions Service: ZMS has a wide range of cable and conductor products for you to choose from. We will provide caring services and professional project solutions for everyone who needs them.

Quality Certification Services: ZMS cable products are manufactured according to GB, IEC, BS, NFC, ASTM, DIN, and other international standards. Our technical team can customize cable products that meet your requirements according to your needs.

Profession Customer Service: ZMS provides free professional consulting services to provide you with one-stop project solution services and rapid product delivery solutions.

Delivery And Shipping Services: While we at ZMS provide high-quality cables, we also provide good delivery solutions. While ensuring the safe delivery of products, we provide the best packaging and transportation solutions, greatly reducing customers’ transportation costs.

Packaging of ZMS: ZMS cable packaging is provided in the form of wooden reels, corrugated boxes, and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.