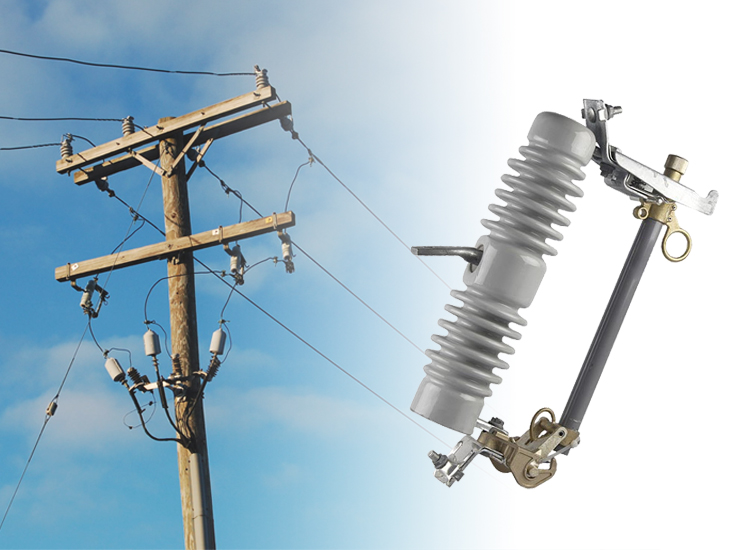

Drop Out Fuse

The Drop Out Fuse series is the most common short circuit protection switch for 10kV distribution line branches and distribution transformers to minimize power outages. Because it has a distinct breakpoint, it functions as a disconnect switch, creating a safe operating environment for maintenance section lines and equipment. It is usually installed on the distribution transformer and can be used as the main protection of the distribution transformer. It is characterized by economy, easy operation, and strong adaptability to outdoor environments. In addition, ZMS products are widely used in the protection of the primary side of 10kV distribution lines and distribution transformers, as well as the operation of equipment switching, which is very popular.

About Drop Out Fuse In Transformer

10-35kv Drop Out Fuse Series

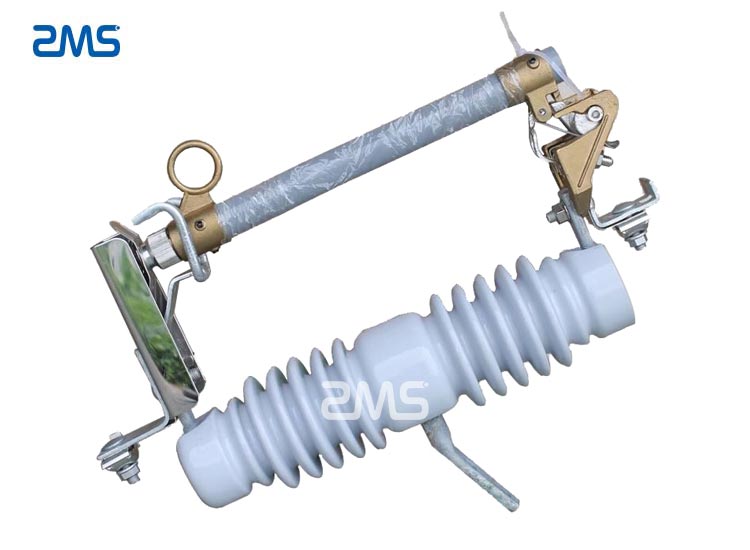

The falling fuse and load falling fuse is an outdoor high voltage protection appliance. It is installed on the high-voltage side of the distribution transformer or the branch line of the distribution line for short-circuit and overload protection of the transformer and the line, as well as splitting and closing the load current.

The falling fuse consists of insulating bracket, fuse tube and components. The static contacts are mounted on both ends of the insulating bracket and the movable contacts are mounted on both ends of the fusing tube. The fuse tube consists of an inner arc extinguishing tube and an outer phenolic paper tube or epoxy glass cloth tube.

Pulling the load down the fuse enhanced elastic auxiliary contacts and arc extinguishing cover for tapping and connecting the current.

10-35kv Current Limiting Fuse Series

A current-limiting fuse is a fuse that can safely cut off all possible currents within its cut-off rated current and current limiting range. It limits the fusing time at rated voltage to be equal to or less than the first mainstream wave or symmetrical current wave period. It also limits the through current to less than the peak current. High voltage high capacity current limiting fuse has a long development, especially the full range fuse for the future can be used as complete protection of medium voltage equipment. This product is suitable for indoor AC 50Hz, rated voltage 3.6kv, 7.2kv, 12kv, 24kv, 40.5kv system. It can be practiced with other switch appliances such as load switches, vacuum contactors. As a protection element for power transformers and other equipment, short circuit, and overload. It is also a necessary supporting product for high-voltage switch frames and high-voltage/low-voltage pre-assembled substations.

10-35kv High Voltage Isolation Switch Series

Installation Tips

(1) The fuse should be stretched tightly during installation (so that the fuse is subjected to a pull of about 24.5 N), otherwise, it will easily cause the contact to heat up.

(2) The fuse should be installed on the crossbar (frame) firmly and reliably, without any shaking or rocking phenomenon.

(3) Fuse tube should be down 25° ± 2° angle of inclination, to facilitate the melted fuse can rely on its weight quickly fall.

(4) The fuse should be installed on the cross-arms (frame) at a vertical distance of not less than 4 m from the ground, and if installed above the distribution transformer. It should maintain a horizontal distance of more than 0.5 m from the outermost contour of the distribution transformer boundary to prevent other accidents caused by drop fuse series tubes.

(5) The length of the fuse tube should be adjusted moderately, requiring the tongue of the duckbill to hold more than two-thirds of the contact length after closing. To avoid the malfunction of falling by itself in operation, the fuse tube should not top the dead duckbill to prevent the fuse tube from falling in time after the fuse melts.

(6) The melt used must be the standard product of the regular manufacturer and has a certain mechanical strength, generally requiring the melt to withstand a minimum of 147 N or more tension.

(7) 10kV drop-out fuse installed in the outdoor, the required distance between phases is greater than 70 cm.

Service of ZMS Cable Company

Over Productions Service: ZMS has a wide range of cable and conductor products for you to choose from. We will provide caring services and professional project solutions for everyone who needs them.

Quality Certification Services: ZMS cable products are manufactured according to GB, IEC, BS, NFC, ASTM, DIN, and other international standards. Our technical team can customize cable products that meet your requirements according to your needs.

Profession Customer Service: ZMS provides free professional consulting services to provide you with one-stop project solution services and rapid product delivery solutions.

Delivery And Shipping Services: While we at ZMS provide high-quality cables, we also provide good delivery solutions. While ensuring the safe delivery of products, we provide the best packaging and transportation solutions, greatly reducing customers’ transportation costs.

Packaging of ZMS: ZMS cable packaging is provided in the form of wooden reels, corrugated boxes, and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.