Karachi Electric Limited (KE) is the only vertically integrated power company in Pakistan. Vertical integration is a method of increasing or decreasing a company’s level of control over the distribution of its inputs and outputs by combining two businesses that are at different levels of the production process.

Through this method, Karachi Electricity Company has been able to continuously inject fresh energy. It also means that the organization manages all three key areas of producing and delivering energy to consumers – generation, transmission, and distribution.

Karachi Electricity Company provides electricity to more than 3.4 million customers through a power network covering 6,500 square kilometers in Pakistan and parts of the country and its surrounding areas in the residential, commercial, industrial, and agricultural sectors.

The company’s home country, Pakistan, is not among the world’s best in terms of power development and even requires assistance from organizations in other countries to function properly in many places. However, Karachi Electricity Company, as the backbone of Pakistan’s power industry, has been actively seeking cooperation with cable manufacturers around the world, striving for high-quality cables. So far, ZMS Cables has had the honor to work with such great power industry partners on projects and provide cable products and assistance for power supply operations in some parts of Pakistan.

STACIR/ AW 230/ 45 New Conductor Project

For this collaboration, ZMS was required to supply STACIR/ AW 230/ 45 new conductors for a project aimed at replacing the existing damaged and unsafe conductor cable TMOH PR 1400036750 in some parts of the local area in Pakistan.

About STACIR/ AW 230/ 45 New Conductor

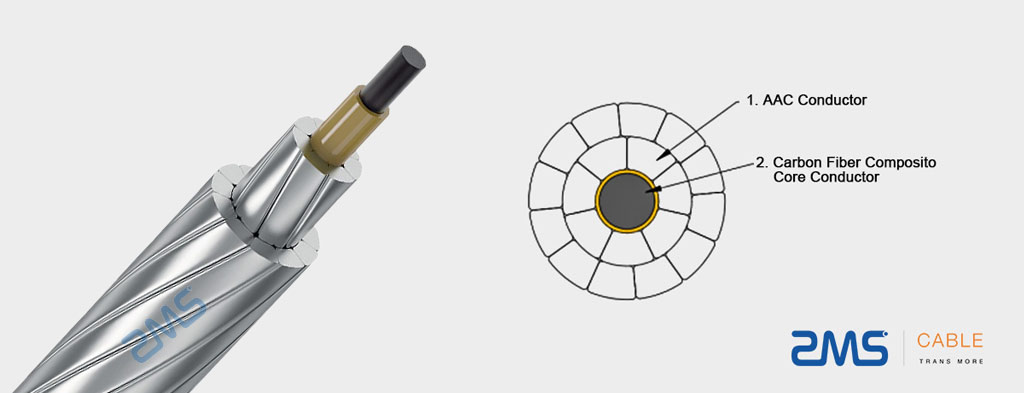

STACIR/AW, known as Aluminum Clad Aluminum Steel Core Super Heat Resistant Aluminum Alloy Strand, is a type of HTLS conductor, which is the full name of High-Temperature Low Sag Conductor, and is widely demanded in the market as a new type of energy-efficient HTLS conductor. The outer layer of the conductor uses a T-shaped aluminum wire construction, which provides more efficient power transmission than traditional round aluminum wires.

ZMS Cables produces a variety of cables using HTLS conductor materials, including ACSS and ACSS/TW, G(Z)TACSR, Yinghua conductor types, ACCR, ACCC/TW conductors, and more.

STACIR/ AW conductors manufactured by ZMS have the following characteristics:

● Can carry up to 100% more current than the same size steel core aluminum strand, while the maximum sag and maximum working tension remain the same as the steel core aluminum strand.

● Does not require modification or reinforcement of existing towers for additional transmission and distribution lines.

●Easy to install, similar to conventional conductors.

●No special hardware/accessories.

● Reduces thermal expansion of the Inva core and improves conductor droop performance.

STACIR/AW conductors are suitable for re-conductor applications. The capacity of existing transmission lines can be realized by simply replacing the existing conductors without any modification of towers.

Local Impact on Pakistan After Replacement

The twin problems of power shortage and inadequate power network coverage have always plagued the country of Pakistan.

As of 2024, Pakistan’s electricity demand is currently still concentrated on the residential side of the equation, with the proportion of industrial electricity consumption being much lower than in comparable developing countries. However, Pakistan’s residential grid access rate has reached 83%, for the development of the country as a whole, is not a very obvious shortcoming, the remaining part of the residential grid access will not have a major impact on the overall power consumption.

So Pakistan’s major power companies are actively seeking cooperation with cable manufacturers to provide them with high-quality cable products, which is very helpful to the development of local power.

Electricity Production in Pakistan

Most of Pakistan’s electricity production comes from its huge hydroelectric projects, but power generation varies with seasonal precipitation, which indirectly leads to the fact that, even if you rely on huge hydroelectric power generation, there will be a shortage of electricity in residential areas.

A similar problem exists with another potential alternative energy source, solar energy. Since much of Pakistan’s basic power generation equipment is not up to the task of sustainably exploiting new energy resources such as solar energy, the use of solar photovoltaic systems to generate electricity also has a more or less certain impact on power consumption. At the same time, Pakistan is beginning to develop its coal resources in a big way.

Impact of Damaged Cables on Power Transmission

The main purpose of this cooperation project is to replace some of the damaged local overhead line conductors. Here ZMS needs to emphasize to everyone that damaged or poor quality cables can have very bad consequences on power transmission.

Insulation Failure: This includes aging, moisture, and damage to insulation due to longevity and weather hazards.

Line Failure: cable and lighting support contact, dynamic loading, seismic vibration changes in ambient temperature, and other causes of breakage and reduce the conductivity of the fault.

Switchboard Faults: faults caused by improper manufacturing quality of switchboards, aging of electrical components, and other reasons.

Safety Accident Hazard

When there is a short circuit or other sudden failure of the line, it is easy to cause electrical fires and explosions. At the same time, the high temperature generated by electric arc and electric heat will cause the surrounding objects to burn and produce thick smoke and toxic gas, which is a great threat to the health of personnel.

Impact of Equipment Damage

The short circuit, open circuit, breakdown, and other cable faults will cause the equipment’s normal work to stop, which in turn will bring many adverse effects on production management. In serious cases, it will also cause the complete scrapping and replacement of equipment, resulting in huge economic and financial losses in production.

Increase in Production Costs

Cable failure will lead to downtime maintenance, equipment replacement, material waste, and other issues, resulting in increased production costs, thus affecting the survival and development of enterprises.

Electricity is an indispensable part of modern industrial production, and cables, as an important part of the power system responsible for the transmission of electricity, carry a huge responsibility. However, cables often have various failures during long-term use, and these failures are very likely to cause accidents, causing serious harm to personnel and equipment.

Therefore, the power staff must do regular testing of cable conditions, even if the replacement of damaged and poor quality cables, to ensure the normal use of electricity in industrial and residential areas.

With this cooperation, ZMS Cable has accumulated more experience in the production of new conductors in the cooperation program.

This cooperation with Karachi has given our new conductors an edge in the Pakistani market, and we have successfully entered the supplier list of K-Electric Limited, and then completed several projects together, which have received unanimous praise.

ZMS is looking forward to standing more firmly in the Pakistani power market, so that ZMS products and technology will be recognized by end users, and lay a solid foundation for more cooperation afterwards.