Optical Ground Wire

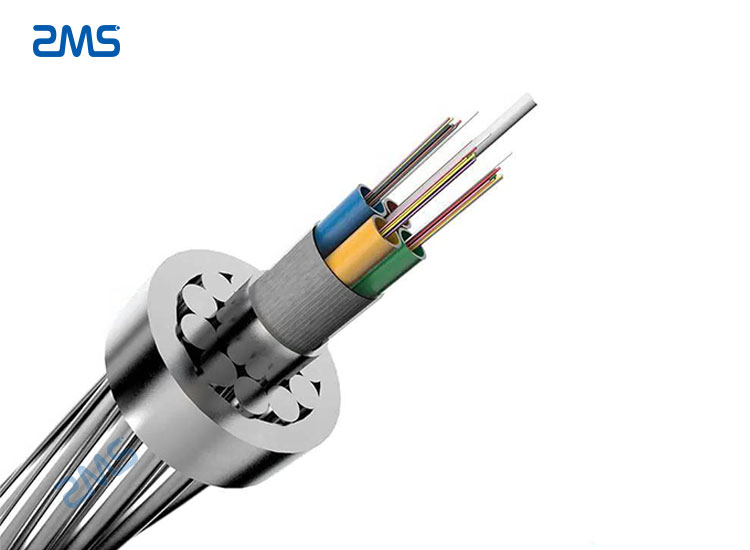

Fiber optic ground wire (OPGW) is a fiber optic placed in the ground of overhead high voltage transmission line to form a fiber optic communication network on the transmission line, which is the most common type of overhead fiber optic cable with the dual functions of ground and communication.ZMS is wrapped with metal wires, which makes it more reliable and solid. The overhead ground line and fiber optic cable are combined into one, which shortens the construction period and saves the construction cost compared with other ways of fiber optic cable.

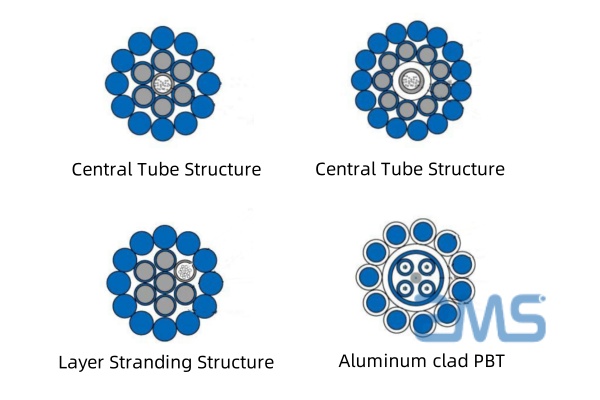

OPGW Cable Types

Aluminum Tube Layer Warping Core OPGW

- Good corrosion resistance

- The non-metallic tube is placed in an aluminum tube. Uniform material structure and good vibration fatigue resistance

- Fiber optic cables are separated from the metallic monofilament when entering the splice box. The end is easier to handle, especially when the fiber is fused.

- Internal non-metallic tubing reduces the risk of damaging fiber optic connections when moving compared to metallic tube edges

Aluminum Tube Center Tube Type OPGW

- Good corrosion resistance

- Uniform distribution of material structure, good anti-vibration fatigue performance

- Short-circuit current has little effect on optical fiber transmission performance

- The cable core is smaller than the aluminum tube type stranded cable core type OPGW, allowing for a smaller structure.

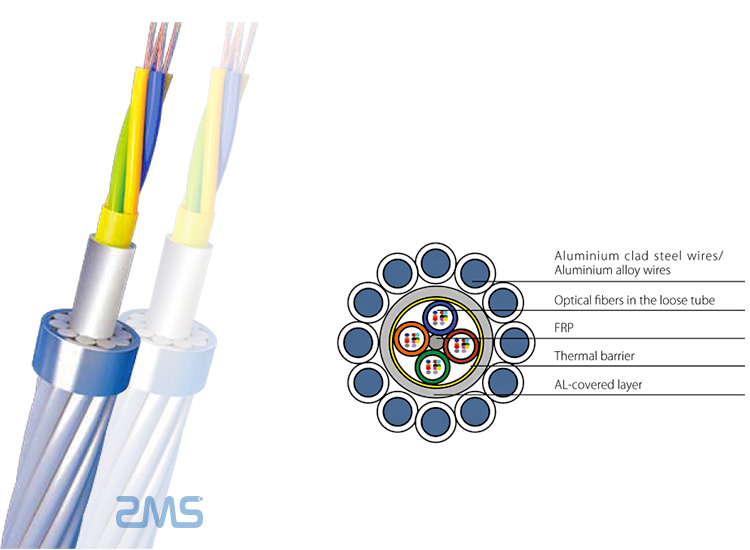

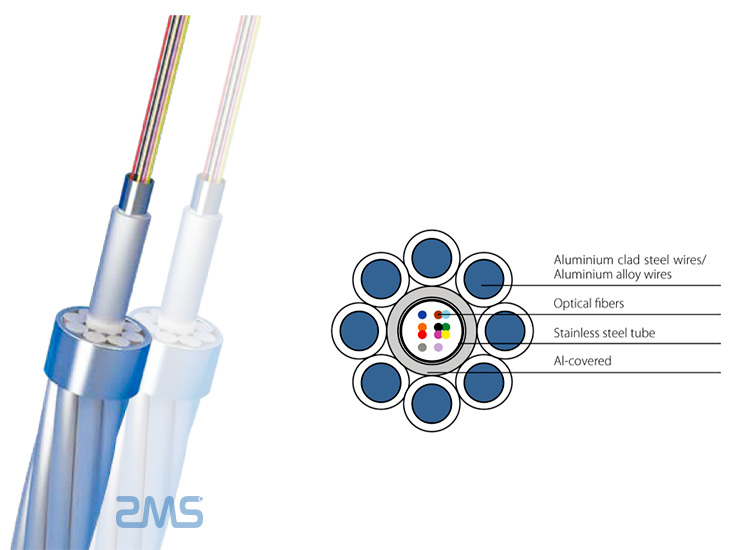

Aluminum Clad Steel Tube Structure OPGW

- Aluminum-clad stainless steel tubes are designed to increase the cross-section of the aluminum for better short-circuit current and lightning strike resistance characteristics.

- High corrosion resistance for corrosive environments, eliminating the need for separate anti-corrosive cable paste.

- Suitable for lines with small cable diameter and large short-circuit current capacity.

- This design can better enable the internal optical fiber to withstand lateral pressure and mechanical protection from the external environment.

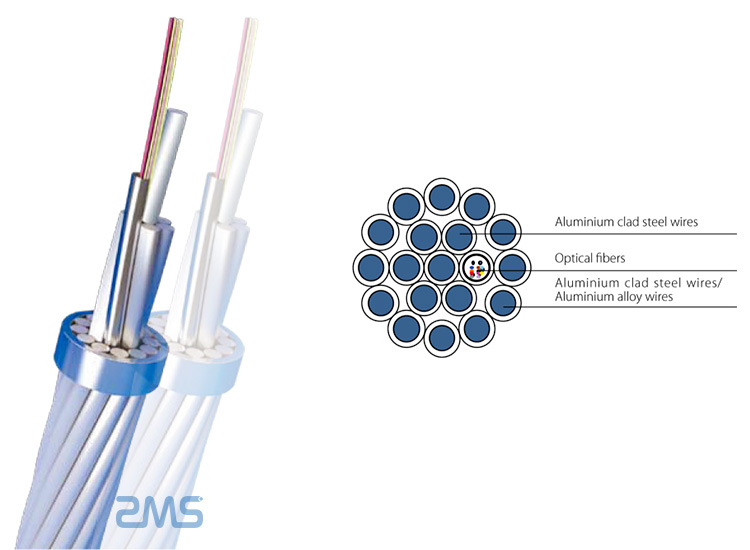

Rust Steel Tube Structure OPGW - Layer Stranded

- The larger the diameter of the fiber optic cable, the greater the number of fiber cores.

- Higher tensile strength and short-circuit current capacity, more balanced mechanical and electrical properties.

- The number of lighting units can be 1 to 3.

- Obtaining the right secondary overgrowth through optimal twist design.

- 2 to 3 layers of outer monofilament, all-aluminum clad steel wire, mixed strands of aluminum clad steel wire and aluminum alloy wire are available.

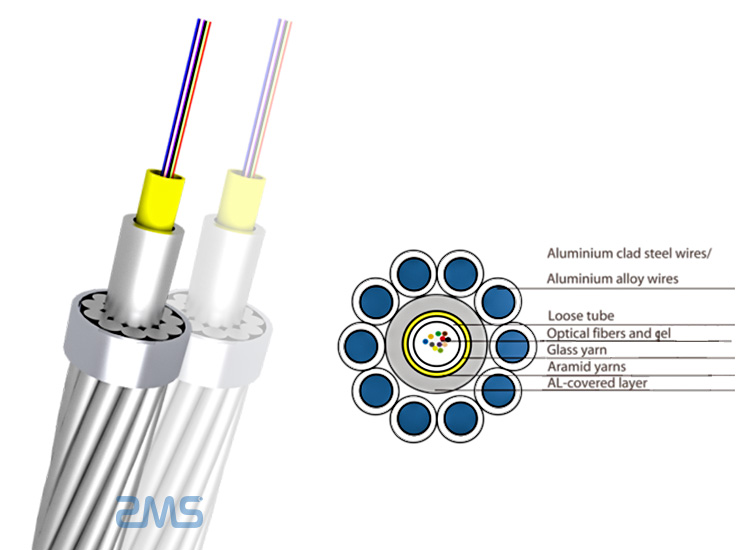

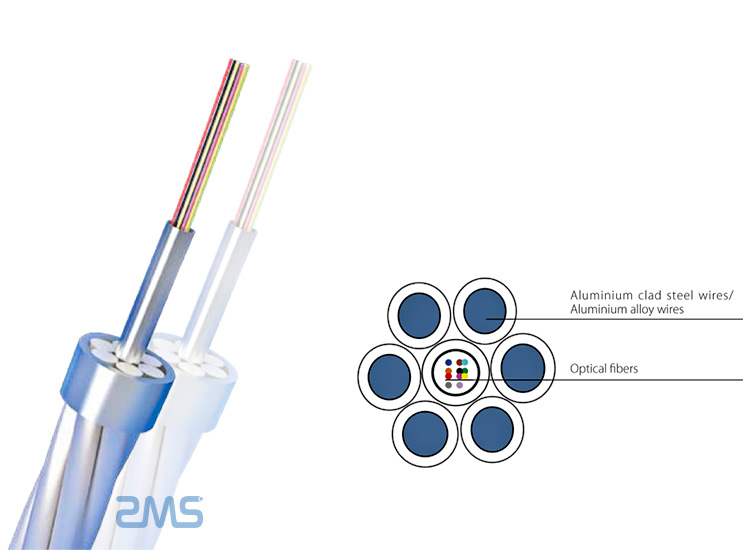

Stainless Steel Tube Structure OPGW - Center Type

- Small cable diameter, light weight and low short-circuit current capacity.

- Higher tensile strength and short-circuit current capacity, more balanced mechanical and electrical properties.

- Slightly poorer resistance to tensile, torsional and lateral pressure.

- Suitable for the renovation of old lines, the fiber has good strain characteristics under high tension.

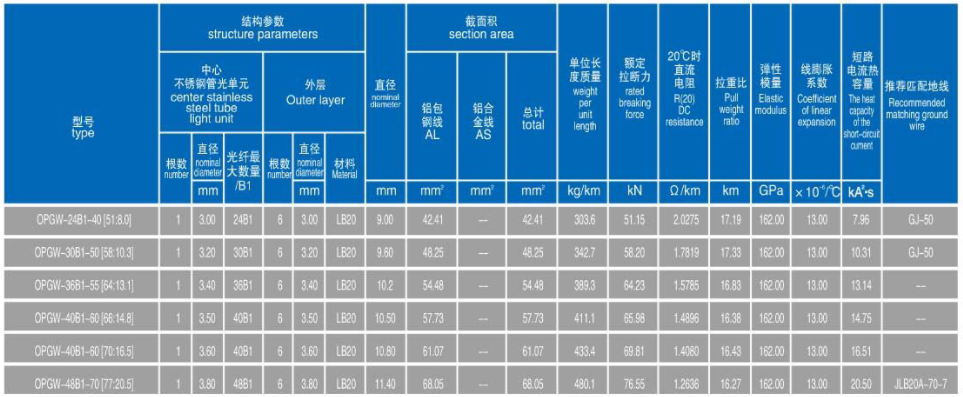

Structure and Erformance Parameters

Feel free to contact ZMS for the rest of the model parameters.

OPGW Optical Cable Application

ZMS OPGW cable in the transmission line can adopt an aluminum tube type, aluminum frame type, and (stainless) steel tube type structure respectively according to user needs. The optical fiber is sheathed in a tube made of stainless steel, the tube is surrounded by aluminum-clad steel wire (AS wire), and the outer layer is wrapped with aluminum alloy wire (AA wire) and twisted into a cable. We customize 2, 4, 6, 12, 24, 48 cores of OPGW optical fiber cable. Meanwhile, the price of our OPGW fiber optic cable is competitive.

• OPGW transmission lines are mainly used on 110KV, 220KV, and 550KV voltage level lines, and are mostly used in newly-built lines due to factors such as line power outages and safety.

• Lines with high voltage exceeding 110kv have a larger range (generally above 250M).

• Easy to maintain, easy to solve the problem of line crossing, and its mechanical characteristics can meet the line of large crossing; The outer layer of OPGW is metal armor, which does not affect high-voltage electric corrosion and degradation.

• OPGW conductors must be powered off during construction, and the power loss is relatively large, so OPGW should be used in newly built high-voltage lines above 110kv.

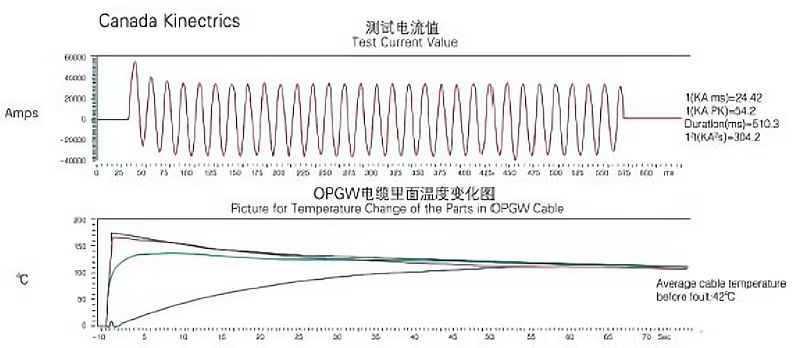

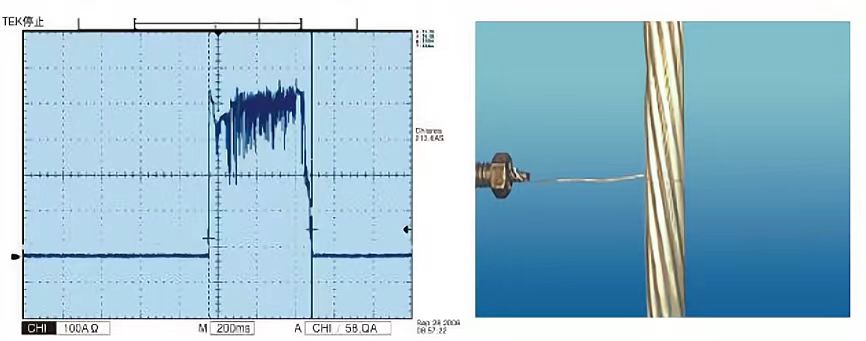

ZMS Test on OPGW

Short-Circuit Current

Flash Arc Test

Cooperation Project Case

| OPGW Types | Project | Quantities |

| OPGW | Jiangsu Province Dongtal power third term | 90 kilometer |

| OPGW-2S-1/24B1-90 | Zhaojiashan and Changfangshan Wind&Power Site | 70 kilometer |

| OPGW-14.6-120-3-24B OPGW-14.6-120-3-12B | Ningxia Huashishan 110KV transmission line | 50 kilometer |

| OPGW-16B-50 | Xinjang shuqin county jinyang wanhua wood industry 35V transmission line | 150 kilometers |

| OPGW-24B1-90 | Puer Kungang Jiahua cement plant supply power project | 15 kilometer |

Why Choose ZMS OPGW?

- Using good stainless steel tube production technology, the tube is filled with water blocking compounds, which can effectively protect the optical fiber.

- Good compactness and high tensile strength.

- The short-circuit current has little mutual interference between the power grid and the communication network.

- Similar to the common ground wire specifications, it is very convenient to erect and can directly replace the original ground wire.

If you don’t know how to choose the product you need or can’t find the cable type and size you need on this page, don’t worry. Contact us and send us your requirements, and we can help you choose the right cable. You can provide us with the following information: cable voltage, conductor material, insulation and sheath material, shield type, armor type, etc. or you can provide us with cable installation environment, application requirements, etc. We will serve you wholeheartedly. ZMS cable supplier has several quality certifications: ISO 9000, ISO 9001, ISO14000, ISO14001, ISO18000, CE, IEC, BS, NFC, ASTM, DIN, etc.

Related OPGW Fiber Cable Accessories

ZMS also produces various types of fiber optic cable accessories, OPGW splice boxes, and so on. The iron or aluminum metal accessories widely used in optical cable products are collectively referred to as fittings. There are many types of fittings with different uses. Most of the fittings need to withstand greater tension during operation, and some must also ensure good electrical contact at the same time. It is related to the safety of the wire or the tower. Even if one is damaged, it may cause a line failure. Therefore, the quality, correct use, and installation of fittings have a certain impact on the safe power transmission of the line.

ZMS Cable Service

Quality Certification Services

ZMS cable products are manufactured according to GB, IEC, BS, NFC, ASTM, DIN, and other international standards. Our technical team can customize cable products that meet your requirements according to your needs.

Profession Customer Service

ZMS provides free professional consulting services to provide you with one-stop project solution services and rapid product delivery solutions.

Delivery And Shipping Services

While we at ZMS provide high-quality cables, we also provide good delivery solutions. While ensuring the safe delivery of products, we provide the best packaging and transportation solutions, greatly reducing customers’ transportation costs.