Since RVV and RVVP have a certain flexibility, they are often used as drag chain cables. However, compared with TRVV drag chain cables, they can only be called ordinary cables. Highly flexible cables have excellent flexibility, not only good bending and stretch resistance, but also have a shielding function, which is incomparable to ordinary flexible cables.

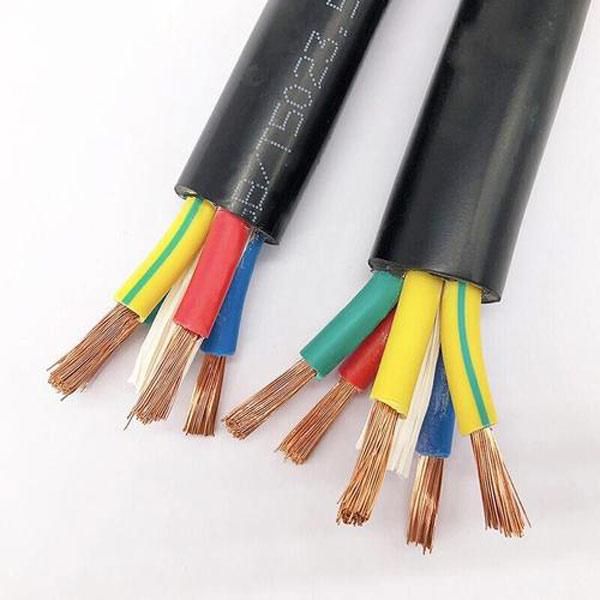

The structure of the conductor is different, the insulation material is different, and the way of forming the cable is different, respectively, using the extruded tube and extruded sheath.

In flexible cables, the cables are frequently bent and moved by forces. Ordinary cables run in such an environment, due to bending force, the core of the cable is compressed, and the overall tension is. Initially, due to the elasticity of the material, the cable can still work normally, but after a period of operation, the material will be deformed due to excessive stress. After this special extrusion process, the cable core forms different areas of pressure and tension, prone to spin phenomenon, the cable may break the core at any time.

Flexible cables are more flexible than ordinary cables. The conductor diameter of flexible cables is very small. However, to protect the conductor, the insulation material with a certain hardness and flexibility to resist machine fatigue and a certain strength is selected. Therefore, the flexibility of flexible cables refers to high flexibility, not high softness. This is something that ordinary cables do not have.

Highly flexible cables are also called special cables. “Special” is the use of special environments in the cable, which is why high-flexibility cables usually have characteristics such as oil resistance, wear resistance, torsion resistance, and bending resistance. This is the ordinary cable can not be compared with its important reason why ordinary cable can not replace high-flexible cable.

So, what is the role of flexible fire cable?

1. Good flexibility: the cable can be coiled on the cable tray, and its bending radius is ≤ 20D, (D for the cable outside diameter).

2. Large cross-section: single-core cable cross-section up to 1000 mm, multicore cable cross-section up to 240 mm.

3. Long service life: inorganic insulation materials, have high-temperature resistance and are not easy to age, the life of organic insulation cable is many times higher.

4. Long continuous length: whether single-core or multicore cable, its length can meet the needs of the length of power supply, each continuous length of up to 1000 m.

5. Corrosion resistance: organic insulation fire-resistant cables sometimes need to wear plastic or iron pipes, plastic tubes are easy to age and become brittle, iron tubes are easy to rust, fire-resistant cables have a copper sheath does not need to wear a tube, copper sheath corrosion resistance is good.

6. Safe and reliable: fire-resistant cable can supply power normally in the flame, reducing fire losses, personal safety is also particularly reliable, its copper sheath is an excellent conductor, is the best grounding PE line, and is continuous to the full length of the cable, greatly improving the sensitivity and reliability of grounding protection.

7. Good shielding performance: fire-resistant cable and information, control, and other lines laid in the same shaft, under the shielding of the copper sheath, will not interfere with the signal, control wire, and cable transmission of information.

8. Exceptional fire performance: fire resistance level not only meets the national standard GB12666.6 Class A 950 ℃, 90 min but also can meet the requirements of the British BS6387-1994 in the A-class 650 ℃ 3h, B-class 750 ℃ 3h, C-class 950 ℃ 3h test. At the same time, burning can also withstand water spray and mechanical impact.