ACSR Conductor

ACSR Conductor, full form Aluminium Conductor Steel Reinforced, is one of the most widely used overhead transmission lines, composed of a steel core and concentrically stranded aluminum wire. It has high tensile strength, high transmission efficiency, light weight, and reliability, making it an ideal choice for long-distance high-voltage transmission projects.

ACSR Conductor Construction

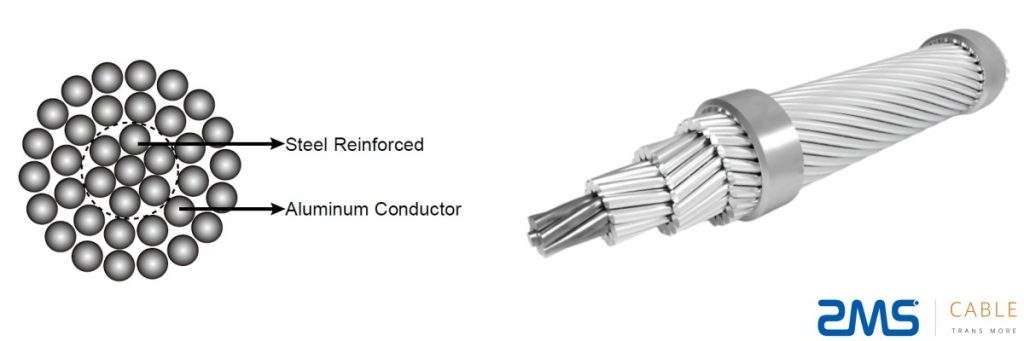

What is an ACSR conductor?

In general, ACSR cable consists of a solid or stranded steel core surrounded by one or more layers of 1350-H19 hard-drawn aluminum wire. The steel core provides tensile mechanical strength, while the concentric aluminum strands carry the current.

Key Structural Features:

- Core: galvanized steel wire or stranded wire (can be single or multiple strands)

- Shell: 1350-H19 hard drawn aluminum wire

- Stranded Wire: concentric stranded wire (usually 6 strands of aluminum wire wrapped around 1 strand of steel wire, or multiple layers)

- Optional Core Types: galvanized, aluminum clad steel (for improved corrosion resistance)

ACSR Conductor Product Features

- High tensile strength for long-span and heavy-load applications

- Good conductivity due to aluminum outer layers

- Galvanized steel core ensures durability and sag resistance

- Lightweight, easy to install and maintain

- Custom sizes and stranding configurations available

- Complies with ASTM B232, IEC 61089, BS 215 standards

- Compared to AAC and AAAC, ACSR wire has better sag control under high temperature or mechanical stress.

ACSR Conductor Sizes & Specifications

Conductor Name | Stranding (Al/St) | Al Cross Section (mm²) | Steel Cross Section (mm²) | Total Area (mm²) | Overall Diameter (mm) | DC Resistance (20°C, Ω/km) | Rated Tensile Strength (kN) | Mass (kg/km) | Standard Conductivity (%IACS) |

ACSR 150/25 | 24/7 | 150 | 25 | 175 | 17.1 | 0.197 | 43.3 | 609 | 61% |

ACSR 185/30 | 26/7 | 185 | 30 | 215 | 18.5 | 0.159 | 52.7 | 740 | 61% |

ACSR 240/40 | 30/7 | 240 | 40 | 280 | 20.7 | 0.124 | 72.4 | 949 | 61% |

ACSR 300/50 | 30/7 | 300 | 50 | 350 | 23.3 | 0.099 | 90.6 | 1113 | 61% |

ACSR 400/65 | 54/7 | 400 | 65 | 465 | 27.4 | 0.074 | 121.5 | 1478 | 61% |

ACSR 500/85 | 54/7 | 500 | 85 | 585 | 30.5 | 0.059 | 151.8 | 1799 | 61% |

ACSR 630/100 | 72/7 | 630 | 100 | 730 | 34.2 | 0.047 | 180.4 | 2204 | 61% |

Note: Data above is based on ACSR construction per ASTM B232 and IEC 61089. Conductivity is based on 1350-H19 aluminum (61% IACS). Strength ratings are nominal and may vary slightly due to steel core coating and manufacturing tolerances. Contact us for specifics.

ACSR Conductor Application

ACSR stranded conductors are widely used in long-distance overhead transmission and distribution networks due to their unique high tensile strength and reliable conductivity.

Long Distance Overhead Transmission

ACSR conductors are ideal for long-distance power transmission across valleys, rivers, and mountains. Their steel-core wires provide the mechanical strength to maintain tension over long spans without excessive sagging. ZMS has provided high-quality ACSR conductors for 110kV and 500kV ultra-high voltage transmission projects, and has gained experience in conductor performance and project solutions.

Severe Weather Areas

Whether in tropical hot areas or severe cold areas, the ACSR cables supplied by ZMS can achieve the maximum power transmission effect with their high-quality manufacturing process and performance. In severe weather environments, the high tensile strength of ACSR conductors can prevent line breakage and strictly limit sagging under heavy loads.

Urban & Industrial Overhead Lines

ACSR is also used for overhead power transmission in urban and industrial environments. It can withstand high mechanical stresses caused by pollution, mechanical vibrations, or wind loads in densely built environments.

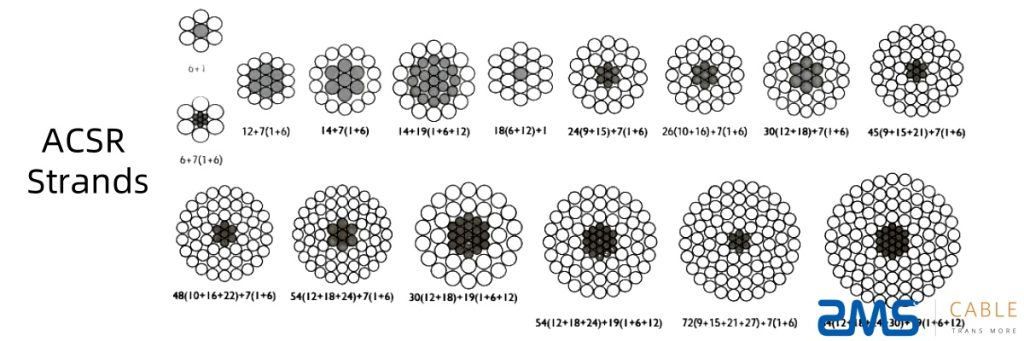

About the Strands of ACSR Conductors

The “strand count” structure is one of the core structural features of bare conductor ACSR, which refers to the total number of aluminum wires and steel core wires in the conductor. This number greatly affects the performance and size of ACSR conductors.

The details are as follows:

| Conductor Name | Stranding (Al/St) | Total Wires | Al Cross Section (mm²) | Steel Cross Section (mm²) | Typical Applications |

|---|---|---|---|---|---|

| ACSR 6/1 | 6 Al / 1 St | 7 | Small sizes (e.g., 25 mm²) | Medium mechanical strength | Short-span, light load |

| ACSR 12/7 | 12 Al / 7 St | 19 | ~80–100 mm² | High strength core | Industrial feeders, tight corridors |

| ACSR 18/1 | 18 Al / 1 St | 19 | ~120 mm² | Lightweight core | Short- to mid-span lines |

| ACSR 26/7 | 26 Al / 7 St | 33 | ~185–250 mm² | Standard strength | Common for HV lines, e.g., Drake |

| ACSR 30/7 | 30 Al / 7 St | 37 | ~300 mm² | Enhanced tensile strength | Rural and intercity lines |

| ACSR 54/7 | 54 Al / 7 St | 61 | ~400–500 mm² | Very high capacity | Long-span or mountainous areas |

| ACSR 72/7 | 72 Al / 7 St | 79 | ~630 mm² | Large conductor with stability | 220–500kV transmission lines |

| ACSR 84/19 | 84 Al / 19 St | 103 | ~700–800 mm² | Extra-high strength | Harsh environment, extra long spans |

| ACSR 112/20 | 112 Al / 20 St | 132 | >1000 mm² | Ultra strength & capacity | Cross-border, ultra HVDC lines |

Note: The number of cable strands is one of the basic design parameters, but it has a direct impact on the selection, current carrying capacity, tensile strength, etc. The appropriate number of strands must be carefully selected.

ACSR Conductor Standard

- ASTM B232 – Stranded Conductors of Aluminum and Steel

- IEC 61089 – Round wire concentric lay overhead electrical conductors

- BS 215 Part 2 – Aluminum conductors, steel-reinforced

- ISO 9001, CE, TUV and other certifications available

ZMS Packing & Delivery

ZMS Cable packaging is provided in the form of wooden reels, corrugated boxes, and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.

FAQ

What are the advantages of ACSR over AAC and AAAC?

Can I customize ACSR conductor size and packaging?

How to get a price or technical datasheet?

ZMS Cable Service

Wide Cable Product Range

As a professional cable manufacturer and exporter, ZMS supplies a complete range of power cables, control cables, instrument cables, and conductors for global industrial projects.

International Standards & Custom Production

Products are manufactured according to IEC, BS, ASTM, DIN, GB, and other standards, with custom cable design available based on technical requirements.

Professional Technical Support

Free pre-sales consultation, product selection guidance, and one-to-one project solution support for different application environments.

Reliable Delivery Solutions

Optimized packaging and shipping plans to ensure safe delivery while helping reduce transportation risks and costs.

Export Packaging Protection

Wooden drums, cartons, or coils packaging with moisture-proof sealed cable ends and waterproof markings for international transport.