BS 6724 Cable

BS 6724 is a British Standard that specifies the requirements for cables used in power distribution systems. Specifically, it outlines the construction and testing requirements for low-voltage cables with thermosetting insulation and a voltage rating of up to 1000V.

BS 6724 cables are designed to be used in a wide range of applications, including fixed installations in buildings, outdoor installations, and underground distribution networks. These cables typically have a copper or aluminum conductor, with cross-linked polyethylene (XLPE) insulation, and a polyvinyl chloride (PVC) sheath.

We supply BASEC-approved low-voltage power cables manufactured to British Standard BS5467 and BS6724. Our state-of-the-art manufacturing facilities and a team of skilled engineers and technicians enable us to produce cables that meet the highest standards of performance and durability.

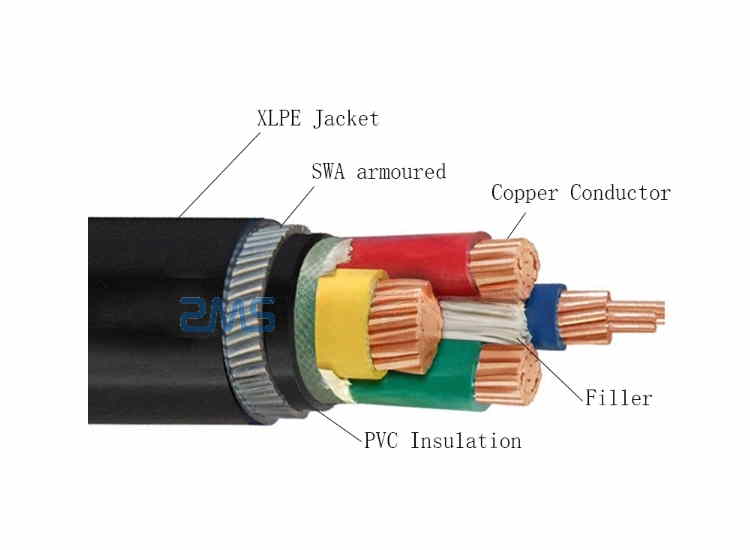

BS6724 Cable Structure and Application

BS 6724 Armored power cable, 600/1000V or 1900/3300V

Applications

This cable is used for power and control circuits, the wire armouring of this cable provides excellent protection. It can therefore be used inside buildings or buried directly underground. It can be installed in environments where fire, toxic fumes or gases may cause life safety or damage to machinery.

Construction

Conductor Solid aluminium or copper conductor, type 2 multi-stranded circular or fan-shaped, according to BS 6360/IEC 60228.

Insulation XLPE (cross-linked polyethylene) GP Category 8 or Ethylene Propylene Rubber GP Category 6

Color coding: 1 core: brown

2 cores: brown or blue

3 cores: brown, black, grey

4 cores: blue, brown, black, grey

5 cores: yellow-green, blue, brown, black, gray

Over 5 cores: white cores with black numbers

Lined with LSOH (Low Smoke Halogen Free)

Armored Single core: AWA (aluminum wire armored)

Multi-core: SWA (steel wire armored)

Outer sheath LSOH (low smoke and no halogen)

Technical Parameters

Rated voltage 600/1000V or 1900/3300V

Rated temperature 0°C to +90°C

Bending radius 1.5mm² to 16mm²: 6 x outer diameter

25mm² and above: 8 x outer diameter

Fire resistant IEC 60332 part 1, BS4066 part 1

Halogen free IEC 60754, EN 50267

Smoke density IEC 61034, EN50268

Technical parameters

Rated voltage 600/1000V

Rated temperature 0°C to +90°C

Bending radius 1.5mm² to 16mm²: 6 x outer diameter

25mm² and above: 8 x outer diameter

Fire resistant IEC 60332 part 1, BS4066 part 1

Halogen free IEC 60754, EN 50267

Smoke density IEC 61034, EN50268

BS 6724 Cable: A Reliable Solution for Low Voltage Power Distribution Systems

BS 6724 is a British Standard that outlines the requirements for low voltage cables with thermosetting insulation used in power distribution systems. These cables are commonly used in various applications, including fixed installations in buildings, outdoor installations, and underground distribution networks.

Construction and Materials

BS 6724 cables typically consist of a copper or aluminum conductor, with cross-linked polyethylene (XLPE) insulation and a polyvinyl chloride (PVC) sheath. The XLPE insulation provides excellent electrical properties, including low dielectric loss, high insulation resistance, and resistance to moisture and chemicals. The PVC sheath offers protection against mechanical damage, UV radiation, and other environmental factors.

Applications

BS 6724 cables are suitable for a wide range of applications in low voltage power distribution systems. They are often used in buildings, such as hospitals, schools, and offices, as well as outdoor installations, including street lighting, traffic signals, and security cameras. Additionally, they are commonly used in underground distribution networks, such as those found in residential areas.

Standards and Testing

BS 6724 cables must meet certain standards and testing requirements to ensure their safety and reliability. These standards include the IEC 60502 and IEC 60228, which specify the requirements for power cables and conductors, respectively. Additionally, BS 6724 cables undergo various tests to ensure they meet the required standards, such as mechanical and electrical tests, voltage tests, and flame propagation tests.

Benefits of BS 6724 Cable

BS 6724 cables offer several benefits over other types of cables used in low voltage power distribution systems. They are highly reliable and offer excellent electrical properties, ensuring that power is transmitted efficiently and safely. Additionally, they are easy to install, with a simple construction that allows for quick and easy termination. They are also highly durable, with a long service life that reduces maintenance and replacement costs.

Conclusion

BS 6724 cable is a reliable and efficient solution for low-voltage power distribution systems. Its construction, materials and testing requirements ensure that it meets the required safety and quality standards. With its numerous benefits, including reliability, ease of installation, and durability, it is an excellent choice for a wide range of applications. If you need a low voltage cable that meets high standards of safety and reliability, BS 6724 cable is an excellent option to consider.

Service of ZMS Company

ZMS Cables is a leading manufacturer of high-quality cables for a wide range of applications. Our products comply with various international standards including IEC60502, IEC60228, IEC60332, IEC60840, etc. It also includes British Standard BS5467, BS6724, BS6387, BS5308, BS6004, etc. Our state-of-the-art manufacturing facilities and a team of skilled engineers and technicians enable us to produce cables that meet the highest standards of performance and durability.

Over Productions Service

ZMS has a wide range of cable and wire products for you to choose from. We will provide caring services and professional project solutions for everyone who needs them.

Quality Certification Services

ZMS cable products are manufactured according to GB, IEC, BS, NFC, ASTM, DIN, and other international standards. Our technical team can customize cable products that meet your requirements according to your need.

Profession Customer Service

ZMS provide free professional consulting services to provide you with one-stop project solution services and rapid product delivery solutions.

Delivery And Shipping Services

While ZMS provides high-quality cables, we also provide good delivery solutions. While ensuring the safe delivery of products, we provide the best packaging and transportation solutions, greatly reducing customers’ transportation costs.

Packaging of ZMS

ZMS cables packaging are provided in the form of wooden reels, corrugated boxes and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.