The Role Of ADSS Fiber Optic Cable

In actual use, the role of fiber optic cable is very much, according to different areas and purposes, and the service is also different. The role of fiber optic cable is mainly communication and transmission of data.

For example, in the network construction of fiber to the home application, we can also access the fiber to the home or outdoors for use. A fiber optic broadband network has a more obvious advantage in that it can be used interchangeably with the ordinary broadband network.

So we can transform and upgrade the fiber optic broadband network to ADSS fiber optic cable for use.

Thus, the ordinary broadband network can be connected to the home or outdoor use.

And it can effectively extend the service life of the fiber optic network. So how to make the fiber optic cable network better?

The following is the ZMS cable team to introduce the fiber optic cable network and ADSS fiber optic cable different use method tips.

ADSS Fiber Optic Cable Laying Precautions

1. The Most Important Point For The Use Of ADSS Fiber Optic Cable Is The Very High Environmental Requirements Of The Fiber Optic Cable.

Using ADSS fiber optic cable, in daily use, pay attention to the environmental requirements of the cable, especially for cathodic radiation, we should pay attention to doing a good job of protective measures. Because cathodic radiation has an important impact on the role of photoelectric conversion. It usually affects the optical range attenuation of optical fiber.

If the moisture content in the air is high, the light decay is fast and the optical fiber optical conductivity will be reduced; if the moisture content in the air is low, the light decay is slow and the optical fiber optical conductivity will be faster.

So the outdoors can often see construction workers with the hand measure the temperature of the fiber optic cable how to measure, fiber optic cable temperature is much higher than the air temperature. After the fiber is buried in the ground generally takes several months to recover the fiber temperature.

So in daily use pay attention to maintaining the moisture of the soil.

Also, be sure to pay attention to the underground laying of fiber optic cable do not use metal materials to protect the fiber optic cable.

Or use a stronger material to protect the fiber optic cable instead of ordinary rubber fiber optic cable.

To avoid accidents and affect the network transmission effect, or even cause network interruption or communication failure and other situations to occur.

The practical application of fiber optic cables often has some problems that lead to the inability to use fiber optic cables.

For example, optical loss is too large resulting in poor network quality, optical cable disconnection, and so on.

If we can not solve these problems in time, then it will affect network communication effect oh.

2. The ADSS Cable For Laying, Should Try To Ensure That The Role Of Stable Ambient Temperature For Laying.

Try to avoid laying fiber optic cables in areas with large changes in ambient temperature.

What are the properties of ADSS fiber optic cable?

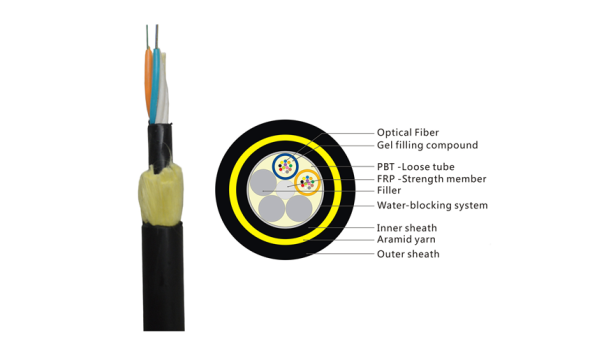

The fiber optic transmission process is mainly composed of several parts such as fiber optic cable, connectors, crimping, and connecting devices.

The first is that the optical fiber has extremely high tensile strength and tear resistance and interference resistance.

The second is that it still has good corrosion resistance under strong electromagnetic field conditions.

Again, the optical fiber has excellent heat and low-temperature performance and good insulation properties.

Finally, the degree of environmental pollution is low.

3. For Some Areas With Harsher Environments, The Use Of Fiber Optic Cable Temperature Should Be As Low As Possible.

At the same time, these areas, especially in summer, should also pay attention to the heat dissipation of optical fiber cables. Optical fiber cable is usually in the form of a multi-core structure.

Therefore, it can be processed into various shapes to meet the needs of different environments. For fiber optic cable, the most important thing is the material used to make the fiber optic cable. Different regions use different fiber optic materials.

For example, fiber optic cables used in cold areas generally use polyester (PET) and polyvinyl chloride (PVC) tubing.

This is because PVC tubing is not only low cost and has excellent corrosion resistance, but polyethylene tubing is lower cost and has excellent corrosion resistance.

However, in some areas, special treatment of PVC pipe is required to meet demand.

In addition, under certain conditions, the use of PVC pipe must meet the performance requirements of PVC pipe and other piping materials.

4. For ADSS Fiber Optic Cable Replacement, It Is Generally Necessary To Replace All The Cores And Cladding.

For ADSS fiber optic cable, we can connect the fiber directly to the home or outdoor use, and then the fiber directly into the ADSS fiber optic cable.

When the fiber optic cable is laid, it is generally laid at both ends of the fiber optic cable and installed with wiring poles or pulling wires. Fiber optic cable trunk laying should use special sleeves for fiber optic cable, should be threaded through the main fiber optic cable and splice box at both ends of the cable, and install the corresponding connection terminal box.

Each fiber can use a special casing. The main optical cable generally uses coreless optical fiber as the outer sheath, and the outer sheath uses polyimide-coated outer sheath, and the outer sheath uses non-insulating materials or elastic materials of composite materials.

The outer sheath is made of polyimide insulation material (such as PVC) with good elasticity, cold resistance, and aging resistance.

Outdoor applications should use coreless optical fiber as the protective layer between the main cable and the outer sheath.

The fiber optic cable outer sheath must use high-strength polyimide epoxy plastic or high-elastic polyolefin material as the outer sheath or the protective layer between the fiber optic cable and the main cable (such as PVC).

5. Before Carrying Out The Construction, The Fiber Optic Cable Must Be Connected To The Outdoor Or Outdoor Trench.

If the conditions allow, you can also lay the cable in the trench, so that the construction is convenient, but also to avoid unnecessary loss of fiber optic cable.

The construction requirements of ADSS fiber optic cable are also very clear.

First of all, we must handle the fiber optic cable correctly, and then it can be used.

But specifically to the construction method, operation, or some small skills that need to pay attention to in the use of fiber optic cable according to the different cases of different treatments.

For some old fiber optic cable lines: it can be used to modify the way to use them. But note that if the old fiber optic lines, the use of the transformation should pay attention to the quality of the cable and cable maintenance.

6. The Newly Laid ADSS Fiber Optic Cable, In General, Needs To Be Maintained And Replaced Every Once In a While.

The specific maintenance time needs to be determined according to the specific circumstances.

Special attention should be paid to the fact that when the new ADSS cable is laid, it should be inspected promptly and replaced in time when problems are found and records are made.

Avoid unnecessary losses due to fiber optic cable fault points, fiber optic cable tripping, and network abnormalities caused by untimely maintenance. In general, once the fiber optic cable is damaged, it needs to be replaced with a new fiber optic cable.

Generally speaking, a normal laying of fiber optic cable takes about 40 minutes to complete the replacement work, if it is necessary to replace the old ADSS cable with new ADSS fiber will take 2-3 hours to complete the replacement work it.

Of course, if you need to pass the fiber optic cable directly through the wall or well and other places that are not very large, you can complete the maintenance and replacement work by replacing the larger fiber optic cable.

The specific case is the use of a length of about 200 meters of ADSS cable for laying. Therefore, in general, the use of a fiber optic cable system ensures that the pipeline in the installation of two fiber optic cable pipes can not overlap.