ADSS Cable Relocation Considerations

1. Verify The Communication Business Carried By ADSS Cable Across The Line

ADSS fiber optic cable usually carries important electric power communication services before removal needs to verify the business carried across the line.

For example, the power supply company verifies all the services carried by the crossed line through the information of the fiber optic cable line, TMS communication management system and the signage hung at the site.

According to the level of bearing business, the ADSS fiber optic cable crossing line is divided into 3 levels, including the crossing line taking the national network business, the crossing line conducting the provincial network business, and the crossing line bearing the local city network business.

2. Determine The Relocation Route

ADSS fiber optic cable spanning line removal before the need to adjust or relocate the route of its bearing communications services. To ensure the reliability of the relocation route, the crossing point is surveyed and the best communication channel is selected to avoid new safety hazards brought by the relocation route.

For example, according to the site conditions of the crossing line, the power supply company mainly adopts overhead under the railroad or down through the power shallow trench to solve the ADSS fiber optic cable high railway crossing hidden problems.

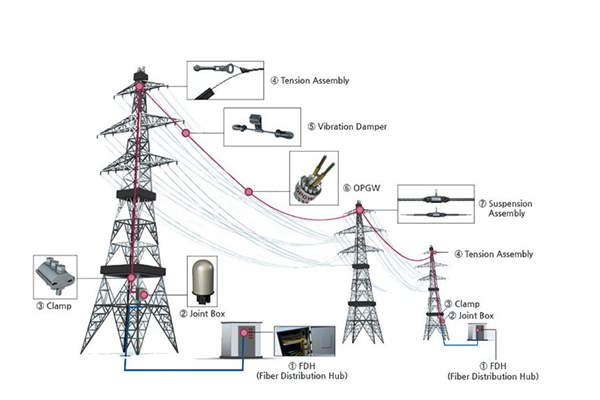

ADSS across-the-line solution can also be replaced across the file of ADSS fiber optic cable into OPGW fiber optic cable.

The advantage of this solution is that the communication reliability is improved after relocation, and the safety factor is higher, which is conducive to later maintenance. However, the main problem with this solution is that the relocation process requires a line blackout, and can only be constructed at night during the time window when high-speed trains are out of service, the construction process is risky and difficult, and the cost is high.

3. Develop a Demolition Plan

To meet the requirements of safe construction, each demolition line should be surveyed on-site, prepare a construction plan corresponding to the site conditions, and review the plan in conjunction with relevant departments.

Take the demolition program: first across the line on both sides of the pylons with tower fasteners and good tensor clamps to be used after the high-speed rail contact network blackout pulley will cross the file ADSS fiber optic cable to the middle direction of the loose line, to be placed on the top of the fiber optic cable loose to the railroad maintenance vehicle, the locomotive operator will then open the fiber optic cable to both sides after dragging away can be completed.

The advantage of this program is that at night without the tower, even if encounter night rain and other bad weather, you can safely remove the optical cable.

In the program, the upper part of the tower with a small pulley as a rotator, but in the actual demolition process ADSS cable tensioning clips are easily stuck in the pulley, resulting in the small pulley can not turn normally.

Several tests proposed using a U-ring instead of a small pulley as a rotator, this way, on the one hand, can avoid the tension wire clip stuck, can not drag the ADSS cable, on the other hand, to avoid repeatedly boarding the tower to recover the small pulley using U-ring to make the cable removal work becomes more safe and efficient.

ADSS Fiber Optic Cable And High-Voltage Transmission Lines With The Tower Erection Operation Problem

ADSS fiber optic cable is currently the most commonly used fiber optic cable for power communication installed in high-voltage transmission lines. Due to the existence of a strong electric field around the high-voltage transmission line, ADSS fiber optic cable exposed to the strong electric field for a long time is prone to damage by galvanic corrosion.

In the voltage level of 110kV and above, ADSS cable electric corrosion damage is one of the main problems faced in the operation and maintenance process.

Electrical corrosion damage in the inspection process is challenging to be found, ADSS cable suffered electrical corrosion damage and is easy to fracture. Especially in the “three spans” (across high-speed railroads, across highways, across important transmission lines), if the cable breaks, it will bring great safety risks to road traffic and transmission lines and may cause serious consequences such as train stoppage, major traffic accidents, and large area power outages.

According to the power supply company ADSS fiber optic cable, long-term operation practice shows that ADSS fiber optic cable and high-voltage transmission lines with the tower erection, easy to suffer from cable electric corrosion failure, and cable breakage accidents.

ADSS fiber optic cable in high-voltage transmission lines after long-term operation, fiber optic cable by its surface water stains, dirt and a variety of atmospheric pollution, in the role of potential spatial difference, the formation of “dry with arc”, arc generated high heat, so that the outer sheath surface temperature rises, resulting in tree-like traces, arc slowly continues to act until burned through the outer sheath, aramid yarn, and finally Sheath, aramid yarn, and finally caused by the fracture of fiber optic cable.

ADSS cable electric corrosion is not easy to detect in the early stage, the later rapid deterioration, and unpredictable, if the cable electric corrosion occurs in the “three spans” position, the fracture of the cable may cause high-speed trains to stop highway traffic accidents, large-scale power outages, and other serious social impact and safety events.