ZMS Fiber Optic Cable Model List

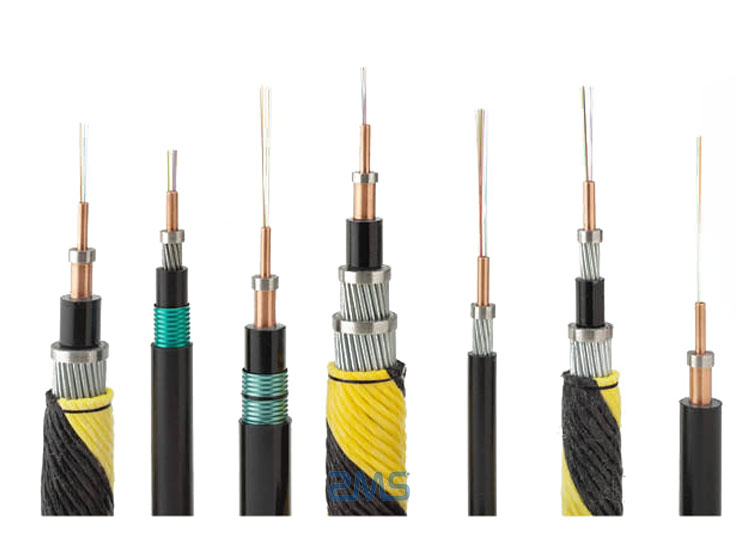

There are many types of fiber optic cables, and the material, structure, and use of different fiber optic cables are also different, to facilitate the distinction and use of fiber optic cables, fiber optic cable manufacturers will usually have a unified code for fiber optic cables. To facilitate the differentiation and use of fiber optic cables, the manufacturers usually have a unified code for fiber optic cables. This not only makes it easier for the manufacturers to differentiate between the cables when making the cables but also helps the customers select the cable. The following is a complete list of common fiber optic cable models.

Fiber optic cable models are generally composed of six parts, namely: classification, reinforcing members, fiber optic cable structural characteristics, sheath, outer sheath, and optical fiber.

GY | Outdoor (field) fiber optic cable for communications | Thick outer packaging, pressure resistance, corrosion resistance, strong tensile strength, suitable for outdoor buildings and interconnection between remote networks, long transmission distance |

GJ | Fiber optic cables in communication rooms (bureaus) | Bend-resistant, fire-resistant and flame retardant, flexible, suitable for communication equipment in buildings, shorter transmission distance |

GH | Communication submarine fiber optic cable | No need to dig tunnels or support with brackets, less investment, faster construction, less interference by the natural environment and human activities, good confidentiality, security and stability, mostly used for long-distance international transmission |

GT | Special fiber optic cables for communication | Dispersion-shifted fibers, non-zero dispersion fibers, dispersion-flat fibers, etc., including all special-purpose fiber optic cables in addition to other classifications. |

GS | Fiber optic cables in communication equipment | Adopting the material of metal heavy-duty reinforcing member and fiber optic loose sleeve cladding structure, it is suitable for deployment in the equipment. |

MG | Fiber Optic Cable for Coal Mining | Addition of flame retardant, anti-rodent characteristics, suitable for coal, gold, iron ore mining occasions |

GW | Metal-free fiber optic cables for communication | Made of non-metallic materials, mainly used in areas with strong electromagnetic influences and lightning prone, etc. |

GR | Communication Flexible Fiber Optic Cable | Smaller outer diameter, good flexibility, easy to bend, suitable for indoor or small space occasions, used in optical connectors, FTTH, sensing and other fields. |

NO | Metal reinforcing elements | Metal, non-metallic, and metal heavy three different materials on the fiber optic cable to strengthen the components, enhance the tensile strength of the fiber optic cable, and improve the mechanical properties of the fiber optic cable. |

F | Non-metallic reinforcing elements | Metal, non-metallic, and metal heavy three different materials on the fiber optic cable to strengthen the components, enhance the tensile strength of the fiber optic cable, and improve the mechanical properties of the fiber optic cable. |

G | Heavy-duty metal reinforcing elements | Metal, non-metallic, and metal heavy three different materials on the fiber optic cable to strengthen the components, enhance the tensile strength of the fiber optic cable, and improve the mechanical properties of the fiber optic cable. |

The structural characteristics of the fiber optic cable should generally include the main type and number of fiber optic cable cores, and the derived structure of the fiber optic cable, when the fiber optic cable type has several structural characteristics that need to be indicated, it can be expressed by the following combination of codes.

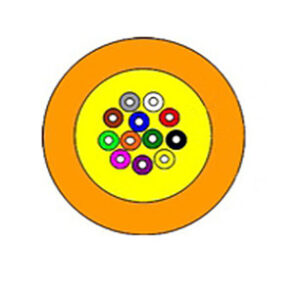

D | Fiber optic tape structure | Put the fiber optic unit into the large casing. Small size, high space utilization, can hold a large number of optical fibers, and splicing of each unit can be completed at once |

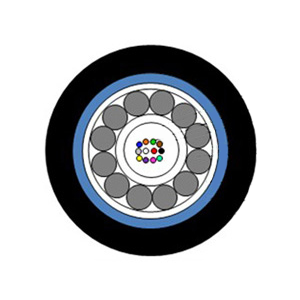

NO | Stranded structure | Adopting bi-directional laminated stranding technology, full cross-section water-blocking, near-zero additional attenuation of optical fiber, and excellent environmental performance. Suitable for long-distance communication, inter-office communication machine for moisture-proof, rodent-proof higher requirements of the occasion |

S | Fiber Optic Loose Sleeve Cladding Structure | Multiple optical fibers are filled in the casing in a free state, consisting of multiple optical fibers, fiber paste, PBT loose sleeve layer, mainly used for outdoor laying. |

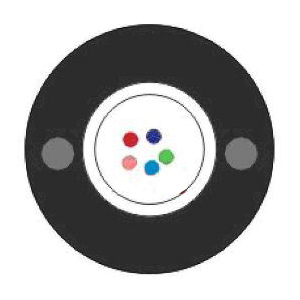

J | Fiber Optic Tight Sleeve Cladding Structure | Composed of optical fiber and the surface of the PVC jacket layer, forming a tight set of fibers, soft, easy to peel, generally used for indoor optical cables or special fiber optic cables |

X | Center tube structure | The loose tube is used as the core and the reinforcing members of the fiber optic cable are around the loose tube. Small diameter, light weight, easy to lay |

G | Skeleton structure | Able to take out the required optical fiber, and access cable for docking, good resistance to side pressure, can well protect the optical fiber |

B | Flat structure | Flat cables with a soft core to ensure flexibility, thin relative thickness, small size, simple connection and easy disassembly, suitable for data transmission or power transmission in electrical equipment. |

T | Filled construction | Fill the inside of the optical fiber to keep the shape of the cable round, play the role of fire, water, pressure, etc. |

Z | Flame retardant construction | Delay the spread of flame along the cable so that the fire will not expand. Lower cost, can avoid major disasters caused by cable fire delayed combustion, improve the level of fire prevention of cable lines |

C | Self-supporting structure | Fiber optic transmission loss is small, low dispersion, non-metallic structure, light weight, easy to lay, strong anti-electromagnetic interference, excellent mechanical properties and environmental performance, suitable for high-voltage transmission lines. |

L | Aluminum | Different types of fiber optic cable sheathing materials vary and play a role in protecting the cable core from external mechanical effects and environmental conditions. |

G | Steel | Different types of fiber optic cable sheathing materials vary and play a role in protecting the cable core from external mechanical effects and environmental conditions. |

Q | Cadmium | Different types of fiber optic cable sheathing materials vary and play a role in protecting the cable core from external mechanical effects and environmental conditions. |

Y | Polyethylene sheathing | Different types of fiber optic cable sheathing materials vary and play a role in protecting the cable core from external mechanical effects and environmental conditions. |

W | Intercalated steel-polyethylene bonded sheathing | Different types of fiber optic cable sheathing materials vary and play a role in protecting the cable core from external mechanical effects and environmental conditions. |

A | Aluminum-polyethylene bonded sheathing | Different types of fiber optic cable sheathing materials vary and play a role in protecting the cable core from external mechanical effects and environmental conditions. |

S | Steel-polyethylene bonded sheathing | Different types of fiber optic cable sheathing materials vary and play a role in protecting the cable core from external mechanical effects and environmental conditions. |

V | PVC sheath | Different types of fiber optic cable sheathing materials vary and play a role in protecting the cable core from external mechanical effects and environmental conditions. |

F | Fluoroplastic | Different types of fiber optic cable sheathing materials vary and play a role in protecting the cable core from external mechanical effects and environmental conditions. |

U | Organosilicon | Different types of fiber optic cable sheathing materials vary and play a role in protecting the cable core from external mechanical effects and environmental conditions. |

E | Polyester elastomers | Different types of fiber optic cable sheathing materials vary and play a role in protecting the cable core from external mechanical effects and environmental conditions. |

0 | Unarmored | A metal protection layer is added to the outermost part of the product to protect the internal utility layer from damage during transportation and installation. |

2 | Double Steel Belt | A metal protection layer is added to the outermost part of the product to protect the internal utility layer from damage during transportation and installation. |

3 | Fine round steel wire | A metal protection layer is added to the outermost part of the product to protect the internal utility layer from damage during transportation and installation. |

4 | Rough round steel wire | A metal protection layer is added to the outermost part of the product to protect the internal utility layer from damage during transportation and installation. |

5 | Wrinkled steel strip | A metal protection layer is added to the outermost part of the product to protect the internal utility layer from damage during transportation and installation. |

6 | Double-layer round steel wire | A metal protection layer is added to the outermost part of the product to protect the internal utility layer from damage during transportation and installation. |

23 | Steel tape armored polyethylene sheathing with winding | A metal protection layer is added to the outermost part of the product to protect the internal utility layer from damage during transportation and installation. |

33 | Fine steel wire-wrapped armored polyethylene sheaths | A metal protection layer is added to the outermost part of the product to protect the internal utility layer from damage during transportation and installation. |

53 | Crumpled steel tape longitudinally wrapped armored polyethylene sheaths | A metal protection layer is added to the outermost part of the product to protect the internal utility layer from damage during transportation and installation. |

333 | Double-layer fine steel wire-wrapped armored polyethylene sheathing | A metal protection layer is added to the outermost part of the product to protect the internal utility layer from damage during transportation and installation. |

44 | Double-layer round steel wire | A metal protection layer is added to the outermost part of the product to protect the internal utility layer from damage during transportation and installation. |

1 | Fiber sheath | The outermost material of optical fiber protects optical fiber from water vapor erosion and mechanical abrasion, increases the flexibility of optical fiber |

2 | PVC sheath | The outermost material of optical fiber protects optical fiber from water vapor erosion and mechanical abrasion, increases the flexibility of optical fiber |

3 | Polyethylene sheath | The outermost material of optical fiber protects optical fiber from water vapor erosion and mechanical abrasion, increases the flexibility of optical fiber |

4 | Polyethylene sheathing with nylon sheathing. | The outermost material of optical fiber protects optical fiber from water vapor erosion and mechanical abrasion, increases the flexibility of optical fiber |

5 | Polyethylene tube | The outermost material of optical fiber protects optical fiber from water vapor erosion and mechanical abrasion, increases the flexibility of optical fiber |

A | Multimode fiber | Can transmit multiple modes with high dispersion and loss, suitable for short and medium distance and small capacity fiber optic communication system |

B | Single-mode fiber | Low dispersion, only one mode can be transmitted, suitable for long-distance transmission |

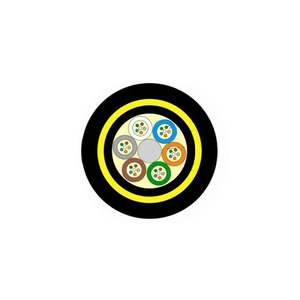

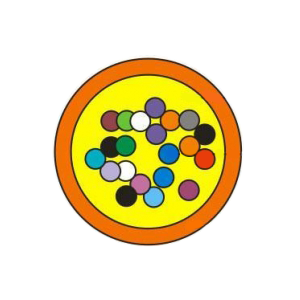

Name | Model | Structural features | Laying method | structural diagram |

Center Tube Fiber Optic Cable | Outdoor communications, metal reinforcing members, center tube, filled, reinforced polyethylene sheathed fiber optic cable | Overhead |  | |

Center Tube Fiber Optic Cable | GYXTS | Outdoor communication, metal reinforced, center tube, filled, steel-polyethylene bonded sheathed fiber optic cable | Overhead |  |

Outdoor communication, metal reinforced, loose layered, filled, aluminum-polyethylene bonded sheathed fiber optic cable | Overhead, piping |  | ||

Stranded Fiber Optic Cable | GYTS | Outdoor communication, metal reinforced, loose layered, filled, steel-polyethylene bonded sheathed fiber optic cable | Overhead, piping, also direct burial |  |

Stranded Fiber Optic Cable | GYTA53 | Outdoor communications, metal reinforcing members, loose-jacketed stranded, fully-filled, aluminum-polyethylene bonded jacket, crumpled steel tape armored polyethylene sheathed fiber optic cable | Buried directly |  |

Outdoor communication, metal reinforced, loose sheathed, stranded, filled, polyethylene sheathed, crumpled steel tape armored polyethylene sheathed fiber optic cable | Buried directly |  | ||

Non-metallic fiber optic cable | GYFTY | Outdoor, non-metallic reinforcing members, fiber optic tape, filled, polyethylene sheathed fiber optic cable | Overhead, high-voltage induction areas |  |

Non-metallic fiber optic cable | GYFTY03 | Outdoor communications, non-metallic reinforcing members, loose sheath laminated stranded, filled, unarmored, polyethylene sheathed fiber optic cables | Hollowed out, channeled, high voltage induction areas |  |

Non-metallic fiber optic cable | GYFTCY | Outdoor, non-metallic reinforcing members, loose-jacketed, stranded, fully-filled, self-supporting polyethylene sheathed fiber optic cable | Self-supporting suspension from towers |  |

Indoor communication, non-metallic reinforcement, tightly sleeved fiber optic cable, polyethylene sheathed fiber optic cable | Indoor pigtails or patch cords |

| ||

Indoor Fiber Optic Cable | GJFJZY | Indoor communication, non-metallic reinforcement, tightly sleeved fiber optic cable, flame retardant polyolefin sheathed fiber optic cable | Indoor pigtails or patch cords |  |

If you don’t know how to choose the product you need or can’t find the cable type and size you need on this page, don’t worry. Contact us and send us your requirements, and we can help you choose the right cable. You can provide us with the following information: cable voltage, conductor material, insulation and sheath material, shield type, armor type, etc. or you can provide us with cable installation environment, application requirements, etc. We will serve you wholeheartedly. ZMS cable supplier has some quality certifications: ISO 9000, ISO 9001, ISO14000, ISO14001, ISO18000, CE, IEC, BS, NFC, ASTM, DIN, etc.