Copper Welding Cable

ZMS produces flexible cables, including hot-selling welding cables, which are usually made of stranded copper conductors and a rubber sheath used as insulation. The most common sheath materials are EPDM and neoprene. We offer Category K and Category M welding cables, including 0361TQ cable in black and orange, as well as H01N2-D and H01N2-E cables. Category K cables are available in sizes from 6 AWG to 500 MCM, and Category M cables are available in sizes from 6 AWG to 4/0 AWG and are available for customization. You can request a quote for your order here.

Product Description

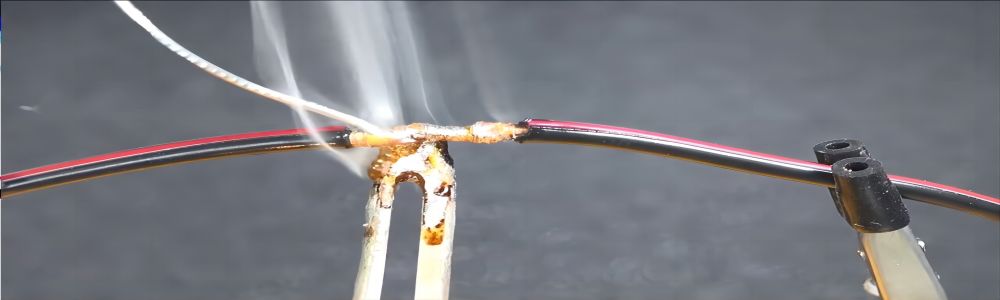

Welding cable, commonly known as welding machine cable, is used for AC and DC electric welding machines, gas welding machines, argon arc welding machines, and other kinds of welding machine output grounding special lines.

The copper welding cable applies to the secondary side of the welding machine wiring and connecting the welding tongs of the special cable, rated voltage AC not more than 200V and pulsating DC peak 400V. The structure of a single core, using multi-stranded soft conductor compound stranded made. The conductive core outside the use of heat-resistant polyester film insulation tape wrapped or temperature-resistant insulation layer, the outermost layer of rubber or PVC made of the sheath as a protective layer.

Construction

Conductor: 6 AWG- 500Kcmil stranded bare copper, flexible, fully annealed, Class K, bare copper.

Insulation: EPDM rubber

Insulation Construction: Single or Double Layer

Color: Black, Orange

Physical Properties

Temperature range: -40°C to 90°C dry, 90°C wet oil and waterproof non-marking jacket, lightweight and very flexible at low temperatures.

Electrical Performance

Rated voltage: 650/1100V

Test AC voltage: 1000V 15 minutes

Minimum bending radius: 12 x cable outer diameter

Product Characteristics

EPDM insulation provides excellent cut, abrasion, and slag resistance, resistance to oils, chemicals, water, ozone, and solvents, acid and alkali resistant, oil resistant, moisture resistant, mold resistant, environmentally friendly

Industry approvals: ASTM B-172, National Electrical Code 630, ROHS

Applications

This type of welding cable is mainly used in a variety of welding equipment and batteries, car batteries, and output current special connection lines.

Welding Cable Size & Spec

| Conductive nominal section (mm²) | Conductive core | Thickness of section sheath (mm) | Average outer diameter (mm²) | 20℃ conductor resistance ≤(k2/km) | Reference weight (kg/km) | ||

| Number /diameter of core(mm) | Min | Max | YH | YHF | |||

| 10 | 322/0.20 | 1.8 | 7.5 | 9.7 | 1.91 | 146 | 153.51 |

| 16 | 513/0.20 | 2.0 | 8.8 | 11 | 1.16 | 218.9 | 230.44 |

| 25 | 798/0.20 | 2.0 | 10.1 | 12.7 | 0.758 | 316.6 | 331.15 |

| 35 | 1121/0.20 | 2.0 | 11.4 | 14.2 | 0.536 | 426 | 439.87 |

| 50 | 1596/0.20 | 2.2 | 13.2 | 16.5 | 0.379 | 592.47 | 610.55 |

| 70 | 2214/0.20 | 2.4 | 15.3 | 19.2 | 0.268 | 790 | 817.52 |

| 95 | 2997/0.20 | 2.6 | 17.1 | 21.4 | 0.198 | 1066.17 | 1102.97 |

| 120 | 1702/0.30 | 2.8 | 19.0 | 24.0 | 0.161 | 1348.25 | 1392.55 |

| 150 | 2135/0.30 | 3.0 | 21.0 | 27.0 | 0.129 | 1678.5 | 1698.72 |

| 185 | 1443/0.40 | 3.2 | 22.0 | 29.0 | 0.106 | 1983.8 | 2020.74 |

Cooperation With ZMS

ZMS Supplies Welding Machine Cables to Pakistan

Type: Welding Cable(Cu/PVC/PVC)

Size: 50m㎡

Subtotal: 5000m

ZMS completed this delivery with a full qualification within the 15-day cycle.

FAQ

Are welding cables safe for everyday use?

Despite their more limited application from the name, Welder cables are ideal for everyday applications, not only for welders, due to their high flexibility but safety measures should always be considered when using them. Because welding cables should not touch water, keep them away from damp grease and wet conditions when used, and always check the wires for defects. If there is any abrasion on the surface of the cable, wrap the welding cable with rubber, plastic, or friction tape. If cable damage is within three feet of the electrode, replace the cable promptly.

How is packaging determined?

ZMS cable factory shipment has decades of experience in packing, woven cloth, cardboard boxes, wooden pallets, wire coils, or bobbins. Please do not hesitate to contact us for any of your transportation needs.

Cable Accessory Service

ZMS Manufacturing has been a leader not only in the production of cables but also in the production of accessories related to cables. Accessories such as connectors and wire lugs are also often required when using welding cables, and there are many types to choose from.

If you don’t know how to choose the product you need, or don’t find the cable type and size you need on this page, don’t worry. Contact us and send us your requirements, we can help you choose the right cable. You can provide us with the following information: cable voltage, conductor material, insulation and sheath material, shield type, armor type, etc. or you can provide us with cable installation environment, application requirements, etc. We will serve you wholeheartedly. ZMS cable supplier has a number of quality certifications: ISO 9000, ISO 9001, ISO14000, ISO14001, ISO18000, CE, IEC, BS, NFC, ASTM, DIN, etc.

ZMS Cable Service

Over Productions Service: ZMS has a wide range of cable and conductor products for you to choose from. We will provide caring services and professional project solutions for everyone who needs them.

Quality Certification Services: ZMS cable products are manufactured according to GB, IEC, BS, NFC, ASTM, DIN, and other international standards. Our technical team can customize cable products that meet your requirements according to your needs.

Profession Customer Service: ZMS provides free professional consulting services to provide you with one-stop project solution services and rapid product delivery solutions.

Delivery And Shipping Services: While we at ZMS provide high-quality cables, we also provide good delivery solutions. While ensuring the safe delivery of products, we provide the best packaging and transportation solutions, greatly reducing customers’ transportation costs.

Packaging of ZMS: ZMS cable packaging is provided in the form of wooden reels, corrugated boxes, and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.