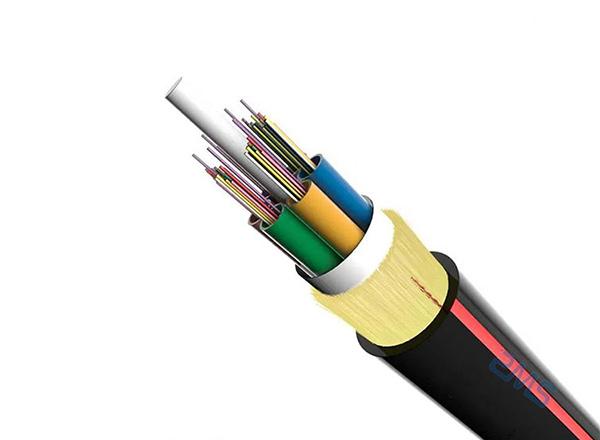

ADSS fiber optic cable is currently the most commonly used fiber optic cable for power communication, which is installed on high voltage transmission lines. Due to the strong electric field around the high-voltage transmission line, ADSS fiber optic cable, which is exposed to a strong electric field for a long time, is easily damaged by electric corrosion.

At the voltage level of 110kV and above, ADSS cable electric corrosion damage is one of the main problems faced in the operation and maintenance process. Electrical corrosion damage in the inspection process is difficult to be found, ADSS cable suffered electrical corrosion damage is prone to fracture, especially in the “three across” (across high-speed railroads, across highways, across important transmission lines) location. If the fiber optic cable breaks, it will bring great safety risks to road traffic and transmission lines and may cause serious consequences such as train stoppage, major traffic accidents, and large area power outages.

Since then, the ICT branch of the power supply company has been actively conducting research on “three-span” management and exploring ways to solve the problem of the “three-span” of optical fiber cable. Based on the inspection and mapping of the “three spans” in the area, the overall plan of “first underpass and bypassing, reducing the risk and promoting the construction of OPGW at the same time” is formulated according to the actual situation of power grid operation. The main transition measure was to bypass the fiber optic cable.

On December 28, 2018, a power ADSS fiber optic cable broke in the Changle section of the Chengdu-Guizhou high-speed railway, damaging the pantograph of the high-speed train and causing the train to stop running for 2 hours. The incident drew the high attention of the electric power department and the railroad department. As a result, the power supply company launched a three-month treatment of ADSS fiber optic cable across the high-speed railway with the cooperation of the Chengdu Power Supply Section of the Railway Bureau. The company completed the investigation, relocation, and removal of all ADSS fiber optic cables crossing high-speed railway lines within the company’s jurisdiction.

According to the ADSS fiber optic cable and transmission line with the tower and rack design method, ADSS communication cable line across the new construction process and other research. There are many introductions to ADSS fiber optic cable construction methods and characteristics. But there is little mention of the experience of ADSS fiber optic cable three-span removal. Therefore, this paper first explains the problem of ADSS fiber optic cable and high voltage transmission line with tower erection operation. Then it introduces the joint survey with the railroad bureau ADSS fiber optic cable across the line ledger. Point by point to determine the relocation and demolition plan, demolition plan optimization, demolition of spanning lines, etc. To provide a reference for other local power supply companies spanning fiber optic cable removal.

According to the long-term operation practice of ADSS fiber optic cable of power supply company, ADSS fiber optic cable is prone to electric corrosion failure and cable breakage accidents when it is erected in the same tower with the high-voltage transmission line. 2018 ADSS fiber optic cable of 220kV Longqing West line of Chengdu power supply company suffered from electric corrosion failure.

ADSS fiber optic cable after a long-term operation on high-voltage transmission lines. The fiber optic cable is affected by water stains, dirt, and various atmospheric pollution on its surface, and under the action of spatial potential difference, a “dry arc” is formed, and the arc generates high heat, which raises the temperature of the outer sheath surface and produces tree-like electric marks. The arc slowly continues to act until burned through the outer sheath, and aramid yarn, and eventually causes the cable fracture.

ADSS cable electric corrosion is not easy to detect in the early stage, the later rapid deterioration, and unpredictability. If the cable corrosion occurs in the “three-span” position, the fractured cable may cause high-speed trains to stop highway traffic accidents, large-scale power outages, and other serious social impact and security events.