The electrician’s electrical assembly needs to connect the various electrical components to be installed and fixed, or connected in series. Then some of the cable accessories and materials they need are electrical consumables. It is also one of the most important parts to support the operation of the entire equipment manufacturing.

Generally in the manufacture of automation equipment, consumables are also related to the entire equipment to improve the process, quality assurance, cost savings, and other factors.

Therefore, in the selection of consumables in addition to the above factors, also consider the use, operation, and maintenance as convenient. Each consumable has its specific role, for example, the wire can only be used to transmit electricity.

Types of Cable Accessories

With the increasing demand of society, product upgrades, and other diversifications, the functions of automation equipment in the manufacturing industry will also be upgraded and diversified by the characteristics of the products.

Automation equipment gradually realizes intelligent, multi-functional, high quality.

At the same time, there is also the disadvantage of complexity and inconvenient maintenance, so the consumable parts used in automation equipment are also diverse.

Although it is said that the cable accessories are very rich in variety, the commonly used electrical supplies are only a specific part.

The functional distinction generally includes: wire class, crimp terminal class, fixed screws, and auxiliary supplies.

Wire Class

1. Definition of Wire

In the electrical automation equipment wire refers to the important material used as wire and cable, industry also refers to wire or wire. Generally made of copper or aluminum, but also made of silver wire, which is used to divert current or conduct heat. Its advantage is that it conducts electricity and heat well.

The main role of cable wire is to be used for the connection between various electrical components, such as the transmission of electrical energy, and signals and the realization of electromagnetic conversion.

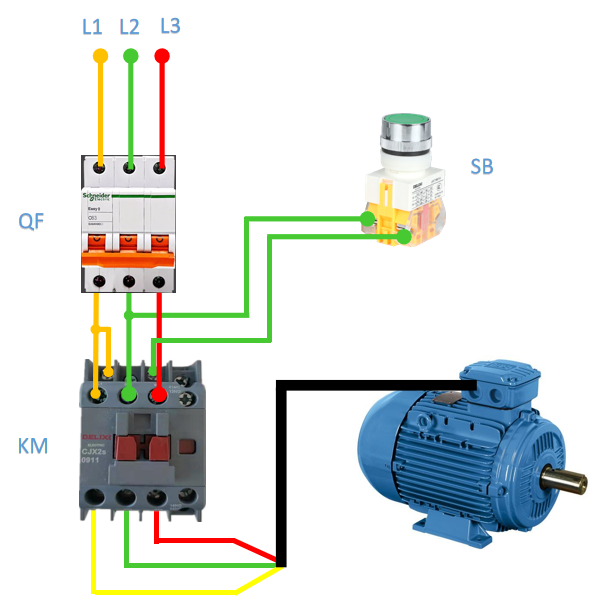

It is widely used in various industries such as daily life and industry. As shown in the figure below.

The starting and running of the motor requires electric energy, and at the same time, through the control elements QF circuit breaker KM contactor, and SB button switch control, the motor is finally realized to run or stop, and then the motor is connected to the electrical components, such as the transmission of electric energy, signal, and electromagnetic conversion.

The final realization of the motor running or stopping, then the wire between them L1, L2, and L3 plays a vital role.

2. Classification of Cable Wires

There are many kinds of wires, which are widely used.

(1) According to the different uses are divided into electronic wire (single-core wire) and cable wire (multi-core wire)

(2) The different materials are divided into copper core wire and aluminum core wire. At present, the most commonly used is copper core wire.

(3) According to the different insulation materials are divided into polyvinyl chloride (plastic) wire, PVC sheathed wire, plastic flexible wire, and so on.

① Electronic Wire (Single-Core Wire)

Electronic wire generally referred to as single-core wire, is the most commonly used unit to form a circuit. Electronic wire is divided into single-stranded copper (aluminum) core wire and multi-stranded copper (aluminum) core wire. Generally used for close connection between individual components.

② Cable Wire (Multi-Core Wire)

Usually by several or several groups of wires (at least two per group) stranded into a rope-like cable, each group of wires insulated from each other, and often twisted around a center, the entire outer cover has a high degree of insulation cover. Cables are characterized by internal energization and external insulation. Generally used for long-distance extension transmission, commonly used in multiple workstation inductors centralized wiring, which is conducive to improving the efficiency of the work, and improve the wiring wiring process. Commonly used cable wire is divided into ordinary multi-core wire, ordinary shielded multi-core wire, ordinary high-flexible multi-core wire, and high-flexible shielded multi-core wire.

3. Cable Wire Specification Meaning

① The structure of single-stranded copper wire contains an insulation sheath and copper wire (aluminum wire).

Usually, the diameter of the copper wire defines the specifications of the wire, such as single-core wire 1mm ² wire.

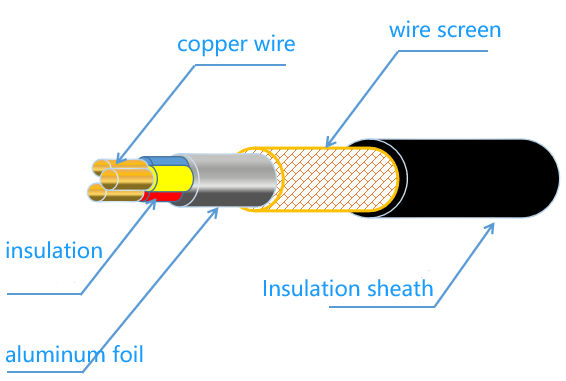

② The structure of multi-stranded cable wires is more complex.

Shielded cable wires contain an insulating sheath, a shielding mesh (layer), an aluminum foil layer, an insulating layer, and a copper core wire.

Cable Accessories Crimp Terminals

1. Definition of Crimp Terminals

Crimp terminals are also called terminals, or cold compression terminals.

Is used to realize the electrical connection of an accessory product, the terminal is the end of the wire connection.

With the increasing degree of industrial automation and industrial control requirements becoming more and more strict, and precise, the amount of terminals gradually rise.

It is mainly used for the connection between the wire, fixed.

The main material system has brass, phosphor bronze, and copper alloy.

To ensure the stability of the terminal and high electrical performance, generally in the surface plating.

Usually plated with gold, tin, nickel, silver, zinc, or chromium, currently the most used is tin-plated.

2. Crimp Terminal Classification

In industrial automation, terminals belong to the category of connectors.

They are generally divided into different functions: European terminal series, plug-in terminal series, transformer terminals, building wiring terminals, fence terminal series, spring terminal series, and rail terminal series.

We are mainly talking about the European style terminals, that is, crimp terminals.

Commonly used crimp terminals for electricians are categorized as follows:

UT Fork-Shaped Pre-Insulated Terminals

Also known as Y-type terminals or U-type terminals general wiring connections are the most commonly used terminals.

OT-Type Insulated Terminals

Also called O-type terminals are mostly used for ground connection, as well as easy to loosen the terminal connection.

Bullet-Shaped Terminals

Also known as banana terminals, they are commonly used in extension cords or butt-wire connections, divided into male and female with the use of.

CE Tube-Shaped Pre-Insulated Terminals

Commonly used in plug-in terminal connectors, PLC, circuit breakers, and other wiring connections.

The Principle of Selection of Electrical Supplies

1. According to the actual needs of the most appropriate choice of consumables

2. Fully consider the issue of cost savings to achieve a high standard of workmanship

3. In the selection of electrical supplies should also consider their safety and reliability

The above is ZMS cable about cable accessories some details. If you have any questions or order requirements in the purchase of cables or accessories, you can consult ZMS cables, there will be a professional cable sales representative to solve your daddy questions.