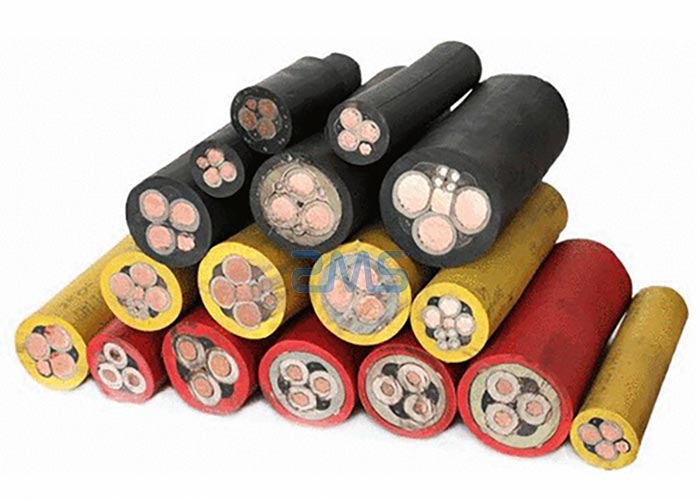

The shielding layer of the cable has different roles in the materials and structures used.

Shielding layer according to the role of wire shielding, insulation shielding, and metal shielding.

1. Wire Shielding

The wire shield is wrapped in the cable conductor surface outside the semi-conductive material. Used in high-voltage cables greater than 3kv to prevent corona generation.

Due to the high-voltage strong electric field the curvature radius of the multi-stranded stranded wire surface, results in the formation of tip discharge corona, affecting the insulation performance, and resulting in energy loss.

In each phase of multi-strand stranded wire wrapped on the outside of the wire shield, increasing the radius of curvature of the wire, uniform electric field, to prevent the generation of the corona, so the wire shield is also known as the pressure belt. Requirements for the wire shield surface are smooth, with no obvious convex lines, sharp corners, and particles.

Conductor shielding using semi-conductive materials is mixed with conductive substances in the insulation material, with a certain degree of conductivity.

Conductor shielding materials are paper insulated cable semi-conductive paper, metalized paper, etc., rubber, plastic insulated cable semi-conductive rubber, semi-conductive plastic, etc.

2. Insulation Shielding

The insulation shield is wrapped in insulation and grounding core outside the semi-conductive material. When phase insulation is broken, the main core is connected to the grounding core by the insulation shield, resulting in a single-phase ground fault. So that the single-phase grounding protection action cuts off power, both to prevent the occurrence of serious phase-to-phase short circuit fault. But also to prevent short-circuit arc caused by gas, coal dust combustion, and explosion.

Therefore, the cable with an insulation shield is especially suitable for supplying power to equipment in places where there is a risk of combustion and explosion. The insulation shield uses the same materials as the wire shielding materials.

For the plastic, rubber cable without metal sheath, the insulation shield consists of semi-conductive material plus metal tape or wire.

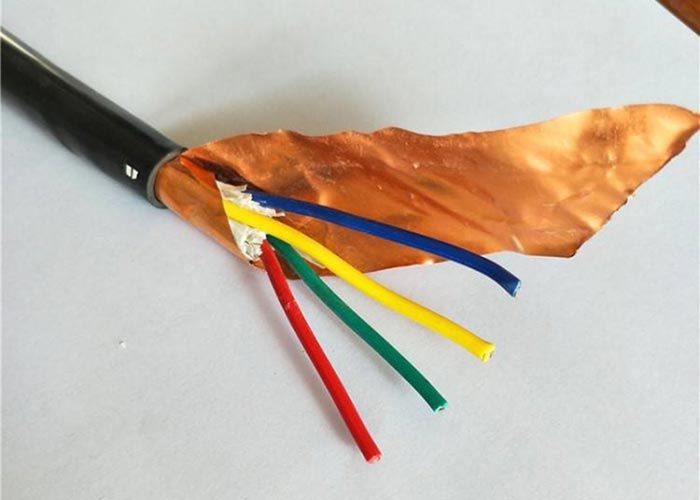

3. Metal Shielding

Metal shielding is wrapped in a unified package of conductive materials outside the insulation, generating electromagnetic shielding to prevent strong electric field radiation interference with communication signals.

So the rated voltage of 3kV or more cables should have a metal shield.

According to the different materials, there are two kinds of copper tape shielding and copper wire shielding.

The former is used for fixed cables and the latter is used for mobile cables.

When using a lead-clad and aluminum-clad metal jacket, the metal jacket can also be used as a metal shield. When the cable is used, the metal shield should be connected to the grounding system.

—ZMS Cable Group