Optical fiber is a light transmission tool that uses the principle of total reflection of light in fibers made of glass or plastic to reach. Compared with copper cables, optical fibers are very fragile and easily damaged, especially during the construction of optical fibers. Today, this article will talk about the seven problems that must be paid attention to during the construction of optical fiber cables.

Problem 1: Not cleaning the fiber before fusion splicing

Cleaning the bare fiber is a very important step before performing fiber optic fusion splicing. It is significant to note that the bare fiber core should be cleaned first before cutting the bare fiber core. There is nothing cleaner than a freshly cut fiber end face, so never clean the fiber after cutting, as this will dirty the fiber end face instead. When cleaning bare fiber, it is highly recommended that operators use a fast evaporating, non-flammable precision cleaning solution.

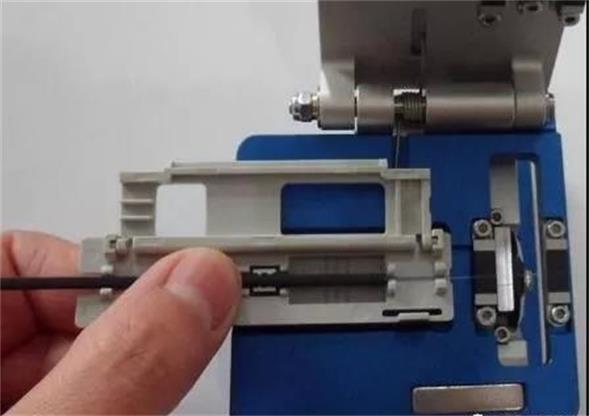

Problem 2: Using improper cutting tools

The smoothness of the fiber end face has a significant impact on the performance of the fused or terminated fiber. In the past, it was common to cut optical fibers manually using fiber optic cutters, which required operators to be systematically trained and skillful. Now, with the advancement of technology, modern automatic cutting tools are common in the market. These tools improve both operator safety and protection of the fiber. Overall, automated cutting tools are an important tool to ensure that the cut fiber end face is qualified.

Problem 3: No calibration before fiber fusion splicing

It is very important to calibrate the fusion splicer. In particular, the strength of the arc or the current strength needs to be adjusted frequently to ensure that the fusion splice is of the right size and that the mechanical strength and optical properties of the fusion splice are strong enough. This is especially important when working under changes in air pressure or at high latitudes. Calibration is quite easy to do, and for most fusion splicers it is as simple as putting the fiber on as if you were going to do a fusion splice. But instead of a real fusion splice, you have to go to the maintenance menu of the fusion splicer and select the option of arc calibration or arc backtest. The fusion splicer will then tell the operator step by step how to perform the calibration. After the calibration is complete, the melt splicer will also remind the calibration is complete or if the entire system needs to be retested.

Problem 4: Micro bend in the fiber

Microbeads in the fiber are usually caused by excessive stress on the fiber. Microbeads in the fiber can cause degradation in signal quality and are difficult to detect with the naked eye unless checked with an OTDR.

Problem 5: Excessive bending of optical fiber

All fiber optic cables have their minimum bending radius, so we should be careful not to exceed the minimum bending radius of the fiber optic cable during construction to avoid damage to the fiber optic cable and the fiber within the sheath.

Problem 6: Reuse of wiping paper/cloth

Reusing wiping paper/cloth is a kind of small loss, this is because when a wiping paper/cloth is used to clean a connector, this wiping paper/cloth is dirty and will be covered with oil and ash layer on your hands, if you use it to wipe other connectors again, it will contaminate other connectors. Of course, if you want to save money, you can buy the smallest size wipe paper/cloth.

Problem 7: Not checking and cleaning the connector end face before installation

The connector end face is also a place that is extremely vulnerable to dust and oil contamination. Therefore, we should inspect and clean the fiber optic connector end face when installing the connector. The cost of a core end face inspection instrument is less than the cost of two on-site repair construction required, you are willing to spend a little money beforehand to do a clean check or after the fact or a large price to repair it?

In summary: the above-mentioned seven are long-standing problems in fiber-optic communications, these problems make the fiber optic network slower, but also often bring network failure. However, as long as the network construction personnel strictly adhere to the standard steps, plus a little care can well avoid these issues.

Error: Contact form not found.