N2XSY cables are versatile, highly flexible, shielded copper conductor power cables for use in industrial automation, machinery, and mobile power systems. Designed in accordance with DIN VDE 0281 and DIN VDE 0282, they offer excellent immunity to electromagnetic interference (EMI), mechanical stress, and environmental compatibility and are suitable for stationary installations or frequently moving applications.

Table of Contents

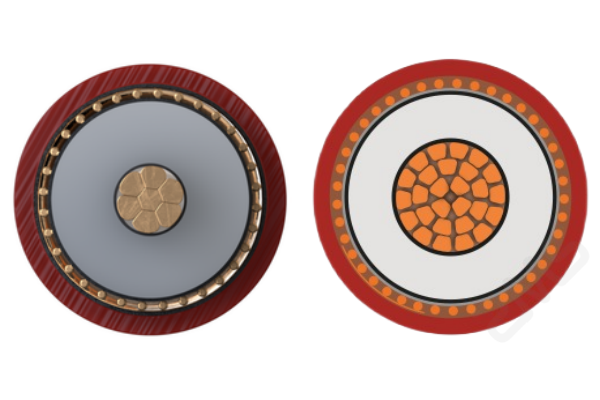

ToggleN2XSY Cable Structure

| Structural Layer | Materials & Specifications |

| Conductor | Multi-stranded fine stranded oxygen-free copper (IEC 60228 Class 5 or Class 6), cross-section range: 0.5 mm² ~ 240 mm². |

| Insulation | PVC (polyvinyl chloride) or TPU (thermoplastic polyurethane), color coded to distinguish phases (e.g., brown, black, gray, etc.) |

| Shielding Layer | Tinned copper wire braid shielding (coverage ≥ 85%), some models with aluminum-plastic composite tape layer (double shielding) |

| Sheath | PVC or PUR (polyurethane), usually black/gray in color, UV resistant, abrasion resistant |

| Optional Additional Layer | Steel wire/polyester braided armor (enhanced tensile strength) |

N2XSY Cable Application Areas

Industrial Automation: robots, CNC machine tools, sensor power supply.

Mobile Equipment: includes cranes, conveyor belts, and drag chain systems (e.g., cable models).

Energy Systems: photovoltaic equipment, internal connections for wind turbines. Building facilities: stage lighting, temporary power supply.

Harsh Environment: oil, humidity, high and low temperature alternating places.

Public Facilities: emergency lighting systems for gymnasiums, schools, and data centers. Transportation hubs: power trunk lines for subways, airports, and tunnels.

N2XSY Cable Technical Specification

| Cross-Section Area (mm²) | Rated Voltage (V) | Insulation Thickness (mm) | Sheath Thickness (mm) | Cable OD (mm) | Weight (kg/km) | Ampacity(A) | |

| Static 30°C | Dynamic 30°C | ||||||

| 0.5 | 300/500 | 0.5 | 0.8 | 4.5 | 35 | 7 | 5 |

| 0.75 | 300/500 | 0.5 | 0.8 | 4.8 | 40 | 10 | 7 |

| 1 | 300/500 | 0.6 | 0.8 | 5 | 45 | 12 | 8 |

| 1.5 | 300/500 | 0.6 | 0.8 | 5.5 | 55 | 16 | 11 |

| 2.5 | 300/500 | 0.7 | 0.9 | 6.5 | 75 | 22 | 15 |

| 4 | 300/500 | 0.7 | 0.9 | 7.5 | 100 | 29 | 20 |

| 6 | 300/500 | 0.8 | 1 | 8.5 | 130 | 37 | 26 |

| 10 | 0.6/1kV | 1 | 1.2 | 11 | 200 | 50 | 35 |

| 16 | 0.6/1kV | 1 | 1.2 | 12.5 | 270 | 68 | 48 |

| 25 | 0.6/1kV | 1.2 | 1.4 | 14.5 | 370 | 89 | 62 |

| 35 | 0.6/1kV | 1.2 | 1.4 | 16 | 480 | 110 | 77 |

| 50 | 0.6/1kV | 1.4 | 1.6 | 18.5 | 630 | 134 | 94 |

| 70 | 0.6/1kV | 1.4 | 1.6 | 21 | 850 | 168 | 118 |

| 95 | 0.6/1kV | 1.6 | 1.8 | 24 | 1100 | 205 | 144 |

| 120 | 0.6/1kV | 1.6 | 1.8 | 26 | 1350 | 235 | 165 |

| 150 | 0.6/1kV | 1.8 | 2 | 28.5 | 1600 | 270 | 189 |

| 185 | 0.6/1kV | 2 | 2.2 | 31.5 | 1950 | 310 | 217 |

| 240 | 0.6/1kV | 2.2 | 2.4 | 35 | 2450 | 360 | 252 |

Note:

Ambient Temperature Correction: For ambient temperatures above 30°C, the flow capacity must be reduced by a correction factor. For example, at 40°C the flow capacity is approximately 90% of the table value.

Correction For Laying Method: When several cables are laid side by side, the current-carrying capacity has to be further corrected according to the spacing and arrangement (refer to IEC 60364-5-52).

Dynamic Installation Life: In drag chain systems, the bending life of the cables is directly related to the installation tension and acceleration and follows the manufacturer’s dynamic parameters.

So, when you have questions about the above data or if it does not correspond to the cable product you need, please feel free to contact ZMS and we will actively answer your questions.

ZMS's N2XSY has the following features

| Electromagnetic Compatibility | Copper braided shielding effectively suppresses high frequency interference and is suitable for sensitive electronic equipment. |

| Mechanical Durability | Sheath is tear-resistant and has a dynamic flex life of > 5 million cycles (drag chain applications). |

| Environmental Adaptation | Oil resistance: Tested to DIN EN 60811-404. |

| Weather Resistance: The sheath is ultraviolet (UV) resistant and suitable for outdoor use. | |

| Electrical Stability | Low capacitance design to reduce signal transmission loss. |

Standards & Certification

Standards: IEC 60228, IEC 60502-1, DIN VDE 0281/0282

Certifications: multiple international certifications owned and supported