Application Of OPPC Fiber Optic Cable

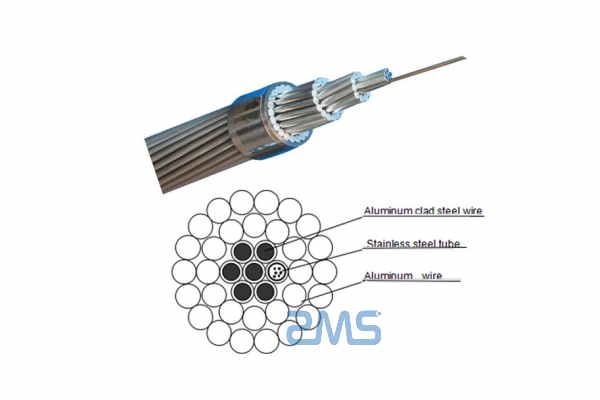

OPPC fiber optic cable is a new type of special fiber optic cable for a powerful communication system.

It is a fiber optic cable with fiber optic units compounded in the wire in the traditional phase wire structure.

It also makes full use of the power system’s line resources, especially the power distribution system, to avoid conflicts with the outside world in terms of frequency resources, routing coordination, electromagnetic compatibility, etc.

Make it has the dual function of transmitting electricity and communication.

OPPC fiber optic cable because of its unique structure of fiber bundle tube inside the wire, so the installation must use a pre-stranded wire fixture to protect the fiber.

The use of pre-stranded wire fittings has three advantages.

First, the construction is easy and fast, without pulling a bulky compressor, crimping pliers, etc. on the site, and labor efficiency and physical labor to reduce.

Second, the pre-stranded wire fixture for a good conductor, good electrical conductivity, and energy-saving effect is remarkable.

Third, the pre-stranded wire fixture installed in the line and the wire contact surface is increased, the length increases and the force is uniform, reducing the fatigue of the wire, extending the life of the wire, improve the ability to prevent earthquakes.

The fiber optic cable erected on the tower, as well as between the fiber optic cable and the guide cable needs to be spliced with a splice box. OPPC cable splicing is the most important part of the entire project.

Compared with other power cables such as ADSS cables and OPGW cables, there are many differences, including the installation method of splice box, splicing method, etc., which are much more demanding than other power cables.

At the same time, there are some new requirements for splicing personnel. Usually, fiber optic cable is not electrically charged, so the design of the splice box does not need to consider this aspect.

But in OPPC, since the current and communication signals are transmitted in one cable. So it is required to connect the communication signal to zero potential level in the splice box to isolate the high voltage and signal safely and reliably and ensure the safe operation of the line.

OPPC fiber optic cable splicing requires the separation of fiber optic units in the operating phase line, involving fiber optic splicing and photoelectric separation technology, the technology of splicing, and high voltage insulation have strict requirements.

OPPC Fiber Optic Cable Installation Requirements

OPPC fiber optic cable is a special self-supporting fiber optic cable, inevitably in the use of the existing disk length configuration and intermediate fusion. The intermediate splice box takes a fusion splice in the upper splice box. The intermediate splice box according to the form of its placement on the tower can be divided into “support” and “hanging” two.

Fiber optic splicing type in the splice box inside the box to complete the fusion and storage of optical fiber, in the external use of parallel trench clamps with the same cross-section of the wire or the same OPPC as a lead wire, splicing jumper connection.

A terminal splice box is required to OPPC fiber optic cable into the communications room, in the terminal when the fiber optic and high voltage current separation, generally using the upper and lower secondary fusion splicing method, can achieve the safe transmission of communication signals.

The upper fusion point is the conductive part, the lower fusion point is after the composite insulator insulation, and the incoming fiber optic cable is connected.

The upper and lower fusion point between the use of pre-buried fiber optic way.

Usually, the intermediate splice box uses a “conductive non-insulated splice box”, while the terminal splice box uses a “high-voltage isolated insulated splice box”.

OPPC fiber optic cable intermediate splice box and terminal splice box have special requirements, in addition to the necessary characteristics of the general splice box, such as waterproof and moisture-proof, a reasonable way to fix the cable, and the appropriate tray fiber structure.

Must also meet the power transmission conductor does not affect ensure the transmission performance of the optical fiber.

OPPC cable connector box uses “high-voltage isolation insulation” technology, to ensure that the OPPC cable line operation insulation safety, reliable, and effective.

OPPC cable spreading construction, installation of OPGW optical cable construction requirements, and precautions can be met. The main problem that should be paid attention to during the construction is the treatment of optical cable joints.

Regardless of whether a suspended intermediate connector box or a pillar-type connector box is used, the placement of the connecting jumper and the size of the arc sag need to be strictly controlled to ensure the spacing to the ground and to ensure sufficient electrical distance.

The installation platform should be horizontal to ensure that the joint box is vertical. For the pillar-type intermediate connection box, need to pay attention to the installation platform set up after the installation of the connector box, its space distance for the tower, should not be less than the spatial distance of the cross-arms hanging point to the tower. The installation platform should be installed firmly with the tower and the connector box.