The ocean covers more than 70% of the earth’s surface and is rich in resources.

The marine ecosystem is the most important in the world, and human survival and development are closely related to the ocean. Nowadays, we can know the world’s affairs without leaving home, and the submarine fiber optic cable buried deep under the sea plays a vital role.

What Exactly Is A Submarine Fiber Optic Cable?

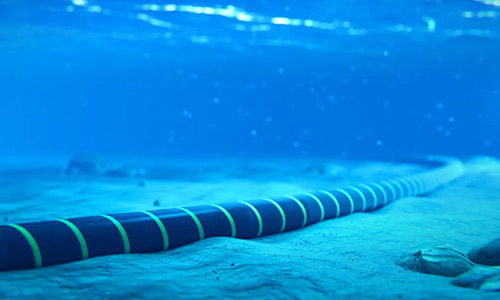

Submarine fiber optic cable is also known as submarine communication cable. Like terrestrial fiber optic cable, submarine fiber optic cable is also used as a transmission medium. The optical fiber is a fiber made of glass, as thin as a hair, and very easy to break. Therefore, it needs to be wrapped and protected with insulating materials, reinforcement, etc., and laid on the seabed for inter-continental information transmission.

What Does The Submarine Fiber Optic Cable System Contain?

The subsea fiber optic cable system is divided into two major parts: onshore fiber optic cable equipment and underwater fiber optic cable equipment. The onshore equipment is used for packaged transmission of voice, image, data, and other communication services. It mainly includes fiber optic cable terminal equipment, remote power supply equipment, line monitoring equipment, network management equipment, marine grounding devices, and other equipment. Fiber optic cable terminal equipment is responsible for signal processing, transmission, and reception at both ends. The detection equipment is responsible for alarm monitoring and fault location. The remote power supply equipment feeds power to the submarine repeater through the conductors in the submarine fiber optic cable.

The underwater fiber optic cable equipment is responsible for processing, transmitting, and receiving the communication signals, which mainly includes fiber optic cable, repeater, and underwater branch unit.

The repeater is also known as a signal amplifier, mainly to achieve long-distance transmission.

The underwater branching unit is to realize the branching of the submarine fiber optic cable and the reversal of the remote power supply.

Submarine fiber optic cable is the most important and vulnerable part of the cable.

Due to the extremely harsh environment, subsea fiber optic cables are constantly under threat of various risks. Such as being damaged by sharks in the sea, natural disasters and earthquakes that lead to interruption of the cable, and marine operations such as fishing within the protected area of the fiber optic cable under the ocean. Once destroyed, it is equivalent to the global communications aorta having problems, causing the impact speaks for itself.

Repairing these cables is not an easy task, to find a small gap in the tens of thousands of kilometers of fiber optic cables that have been damaged is like looking for a needle in a haystack, the difficulty of repair can be imagined. At this point, people need to determine the approximate location of the damage by transmitting signals from both ends of the fiber optic cable, using underwater robots to pinpoint and cut this section of the cable, pull the damaged cable out of the sea, connect and repair it by engineers, and then put it into the sea floor and restore it to its original state by robots.

Submarine Cable Laying

Submarine cable laying mainly includes: cable routing survey and cleaning (before), submarine cable laying (in), and flush burial protection (after) in three stages.

Before The Laying of Submarine Cable—A Cable Routing Survey

Including cleaning up the water depth of the sea routing area, topography, shallow stratigraphic profile measurement, sediment surface sampling, column sampling, and static touch survey. It also includes surveys of traffic and construction conditions and obstructions that reflect the status of marine development activities.

Recently, the use of advanced GPS post-processing positioning and (CPT) static touch technology has led to a significant increase in survey speed and effectiveness.

Submarine Cable Laying—Recognized as a Complex and Difficult Large-Scale Project

The undersea cable laying should control the angle of the cable into the water and the laying tension by controlling the sailing speed of the laying vessel and the cable release speed to avoid damaging the cable due to too small a bending radius or too much tension.

In shallow seas, such as water depths of fewer than 200 meters the sea cable using buried. And in the deep sea, laying is used, and the cable is released by the cable laying vessel. Use an underwater monitor, or underwater remote control vehicle to constantly monitor and adjust to control the forward speed and direction of the laying vessel and the speed of laying the cable to avoid damaging the cable by bypassing the uneven places and rocks.

After The Laying of The Subsea Cable—Flush Buried Protection

In the final stage of construction, the main purpose is to protect the submarine cable by deep burial to reduce the impact of the complex marine environment on the deep sea cable and ensure operational safety.

In the sand and silt area, a trench about 2 meters deep is generated by high-pressure flushing water, into which the cable is buried and covered by sand next to it.

In coral reef and clay areas, cut a 0.6-1.2 m deep trench with a cutter, bury the cable into the trench and backfill it naturally to form protection.

In hard rock areas, the cable needs to be covered with a cement cover and other hard objects to implement protection.

Currently, the submarine network carries more than 99% of the data traffic of intercontinental communications and has become an important part of the entire optical communication infrastructure. For various oceanic fiber optic cable application scenarios, ZMS Cable has introduced several fiber optic products that seek a balance between ultra-low loss and cost optimization for both repeater and repeaters marine space division multiplexing (SDM) systems. Offering the largest effective area and ultra-low attenuation coefficient, it can support the maximum single core capacity. Provides industry-leading attenuation performance for ultra-long-range, high-rate SDM systems.