Airfield Lighting Cable

Airfield Lighting Cables secure airport equipment such as aircraft taxiways, runway navigational aids, and obstruction lights. They can be directly buried or ducted.

About ensuring the safe operation and landing of airports, ZMS Airport Lighting Cables has developed a range of solutions that are resistant to problems such as water, UV rays, oil, and grease, and that ensure the continuous and stable operation of airport runways, taxiways, and airport building lighting systems. In addition, our airport cable installation guide covers a full range of services, from cable types by application-specific requirements and national standards to on-site international logistics.

Airfield Lighting Cable Types

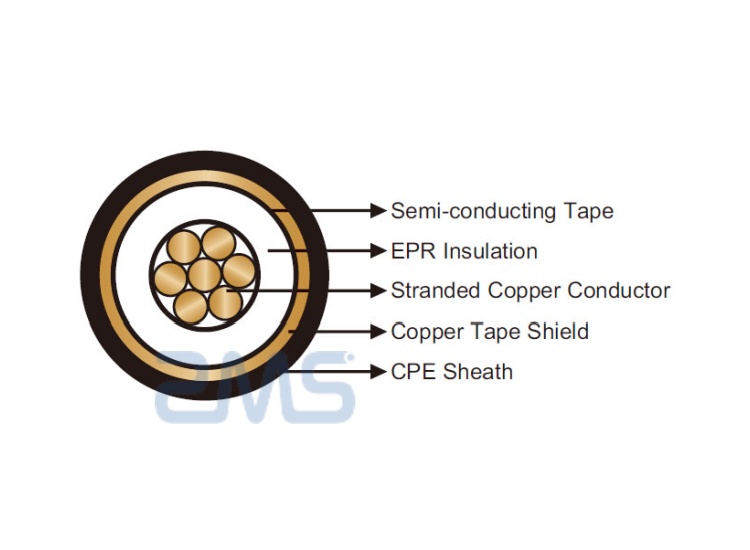

FAA L-824 Type B Shielded 5kV

Conductor: Stranded tinned copper conductor.

Insulation: EPR.

Semi-Conductor: Helically applied semi-conducting tape.

Shield: Tinned copper tape.

Separator: Separation tape.

Sheath: CPE.

FAA L-824 Type B Shielded 5kV Cable is often installed in transformers and current regulators in series airport lighting systems for fixed applications such as taxiways, runways, navigational aids, and obstruction lighting. It can be installed in bushings or buried directly in the ground.

Standards: FAA L-824 Type B/ICEA S-93-639 / NEMA WC74

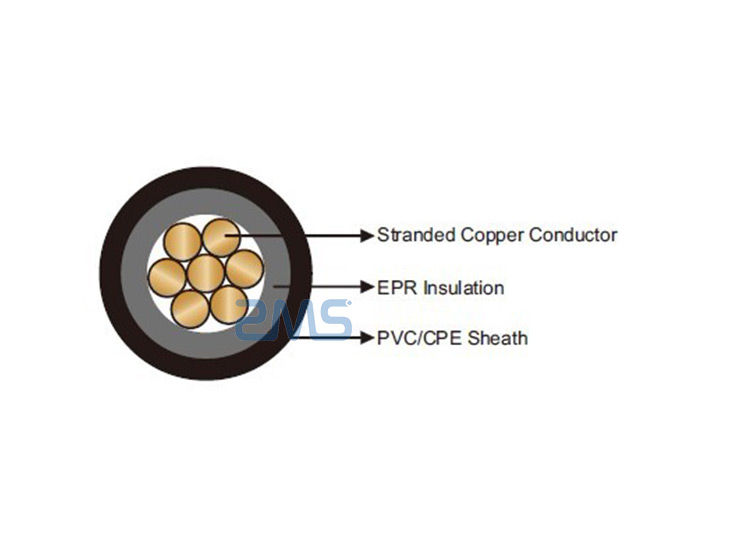

FAA L-824 Type B Unshielded 5kV

Conductor: Stranded bare or tinned copper conductor

Insulation: EPR

Outer Semi-Conductor: Extruded semi-conducting compound.

Out Sheath: HDPE/PVC

Voltage Uo/U (Um): 5kV

Operating Temperature: -40℃~+85℃

Halogen-free: Yes

Oil Resistant: Yes

FAA L-824 Type B Unshielded 5kV Airport Lighting Cable is used to connect transformers and current regulators in series circuits for airport lighting systems and is suitable for stationary applications such as taxiways, runway aids, and obstruction lights, and can be buried or ducted.

Standards: FAA L-824 Type B, ICEA S-96-659/NEMA WC71

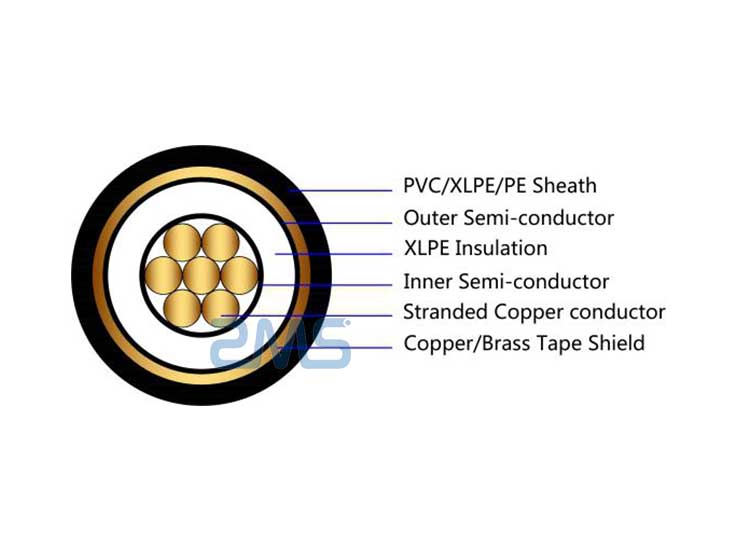

FAA L-824 Type C Shielded 5kV

Conductor: Stranded bare copper conductor, IEC 60228 class 2

Inner Semi-Conductor: Extruded semi-conducting compound

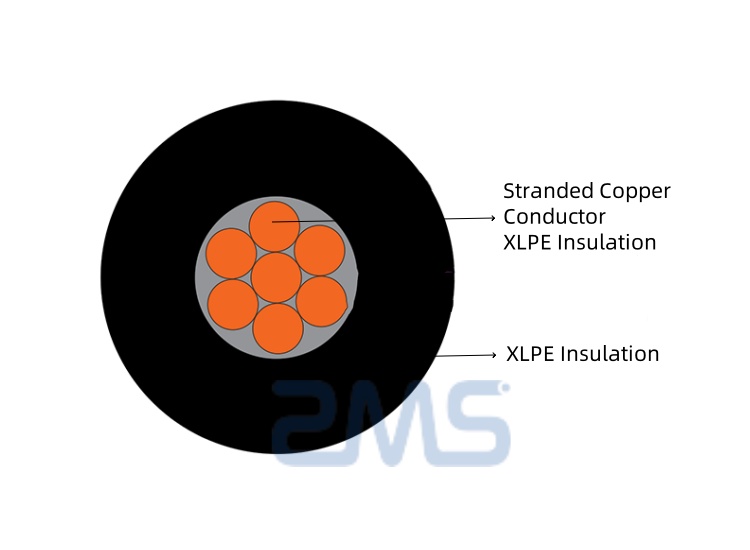

Insulation: XLPE

Outer Semi-Conductor: Extruded semi-conducting compound

Shield: Two copper tapes

Outer Sheath: PVC/HDPE

FAA L-824 Type C Sheathed 5kV Airport Lighting Cable is used to connect transformers and current regulators in series circuits for airport lighting systems and is suitable for stationary applications such as aircraft taxiways, runway navigational aids, and obstruction lights, and can be buried or ducted.

Standard: IEC 60502, IEC 332-3, IEC 60228, FAA AC 150/5345-7E

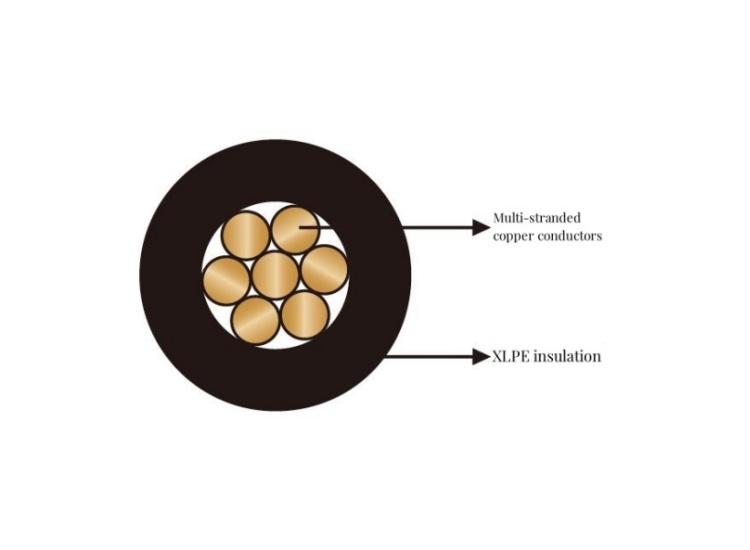

FAA L-824 Type C Unshielded 5kV

Conductor: ASTM B multi-strand bare copper conductor.

Insulation: XLPE.

Sheath (for multi-core cables only): PVC.

Voltage Uo/U (Um): 60kV

Maximum conductor temperature: 90℃

Short circuit temperature: 250℃

Operating Temperature: -40℃~+90℃

Minimum bending radius: 5×OD

FAA L-824 Type C is suitable for airport lighting and control circuits and is suitable for both conduit and direct burial laying.

Standards: FAA L-824 Type C, ICEA S-95-658/NEMA WC71

FAA L-824 Type C 600V

Conductor: Stranded bare copper to ASTM B.

Insulation: XLPE.

Sheath (optional): PVC

Rated Voltage: 600V

Maximum Conductor Temperature: 90℃

Operating Temperatures: -40℃~+90℃

Minimum Bending Radius: 5×OD

This type of cable falls within the low-voltage range and is commonly used for airport lighting and control circuits. It is suitable for installation in pipes, conduits, or direct burial in the ground.

Standards: FAA L-824 Type C/ICEA S-95-658/NEWA WC71

Conductor: Stranded bare copper

Insulation: Special cross-linked elastomer / EPR

Sheah: Special cross-linked elastomer / EPR

Operating Voltage: U0 450/750V

Maximum Conductor Temperature: 85℃

Short Circuit Temperature: 200℃

Operation Temperature: -20℃ to + 85℃

Minimum Bending Radius: Static: 4×OD; Dynamic: 8×OD

H07RN-F lighting cable, this model is often exported to European countries. It is also usually called VDE rubber cable, outdoor rubber, etc. It is highly flexible and resistant to weather, oil/grease, and mechanical and thermal stresses.

Standards: NF C 32-102-4, HD 22-4

Airfield Lighting Cable Specifications

If you don’t know how to choose the product you need, or don’t find the cable type and size you need on this page, don’t worry. Contact us and send us your requirements, we can help you choose the right cable. You can provide us with the following information: cable voltage, conductor material, insulation and sheath material, shield type, armor type, etc. or you can provide us with cable installation environment, application requirements, etc. We will serve you wholeheartedly. ZMS cable supplier has a number of quality certifications: ISO 9000, ISO 9001, ISO14000, ISO14001, ISO18000, CE, IEC, BS, NFC, ASTM, DIN, etc.

Partnering with ZMS

Airport Lighting Project with Jordan

ZMS provides the following cables:

- Airfield cable 6kV Cu/XLPE/CTS/PVC 6kV 10mm2(1000m )

- Airfield cable 6kV Cu/XLPE/CTS/PVC 6kV 6mm2(1000m)

ZMS guarantees the production and smooth delivery of cables within 15-20 days and promises a warranty period of 18 months.

Cooperation with Saudi Infrastructure Project

ZMS provides the following cables:

- 8 AWG primary cable screened 5kv (1200m)

ZMS successfully delivered and arrived at Dammam airport within 25 days as per the client’s requirements, committed to a warranty period of 18 months and assisted in providing multiple product qualifications.

Service of ZMS Company

Over Productions Service: ZMS has a wide range of cable and conductor products for you to choose from. We will provide caring services and professional project solutions for everyone who needs them.

Quality Certification Services: ZMS cable products are manufactured according to GB, IEC, BS, NFC, ASTM, DIN, and other international standards. Our technical team can customize cable products that meet your requirements according to your needs.

Profession Customer Service: ZMS provides free professional consulting services to provide you with one-stop project solution services and rapid product delivery solutions.

Delivery And Shipping Services: While we at ZMS provide high-quality cables, we also provide good delivery solutions. While ensuring the safe delivery of products, we provide the best packaging and transportation solutions, greatly reducing customers’ transportation costs.

Packaging of ZMS: ZMS cable packaging is provided in the form of wooden reels, corrugated boxes, and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.