A2XS(FL)2Y HV Cable is a single-core aluminum conductor XLPE cross-linked polyethylene insulated power cable, featuring a copper wire shielding layer, a longitudinal water-blocking layer, and a black PE polyethylene outer sheath. This cable is specifically designed for underground high-voltage power distribution networks, industrial substations, and renewable energy projects such as wind farms and solar power plants.

Table of Contents

ToggleWith its excellent electrical performance, high mechanical strength, and reliable water-blocking design, the A2XS(FL)2Y cable is suitable for fixed installation methods such as conduits, trenches, and direct burial.

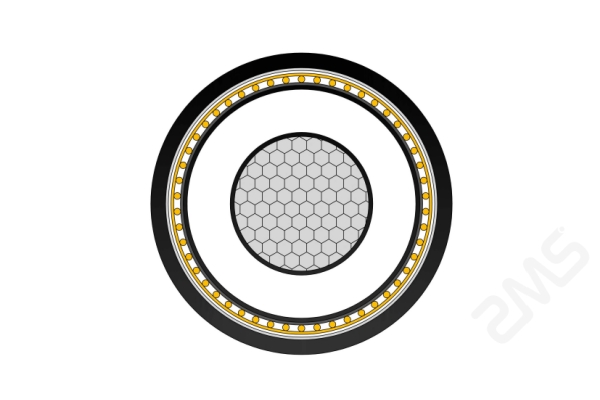

A2XS(FL)2Y HV Cable structure

Material: Aluminium (Al)

Class: Class 2 stranded, circular or sector shaped

Cross-sections: 70 mm² up to 630 mm² (other sizes on request)

Semi-conductive layer extruded over the conductor

Ensures smooth electric field distribution and reliable bonding to XLPE insulation

Cross-linked polyethylene (XLPE)

Nominal insulation thickness depending on voltage rating (e.g. 3.4 mm, 5.5 mm, 8.0 mm)

Max. conductor operating temperature: 90°C

Semi-conductive XLPE inner screen

Compatible with the insulation to avoid partial discharges

- Annealed copper wire shielding layer with water-blocking function

- A longitudinal water-blocking element (expansion tape/powder) is provided between the insulating shielding layer and the metallic shielding layer

- Effectively limits water infiltration in case of cable core damage

Material: Black PE (Polyethylene)

UV resistant, weather and moisture resistant

Suitable for underground and outdoor installations

Technical Characteristics

| Test voltage | Max. conductor temperature | Max. short-circuit temperature (5s) | Mechanical & Installation Properties | ||

| according to IEC / VDE standard | 90°C | 250°C | Minimum bending radius | Installation temperature | Resistant to moisture, UV and most common chemicals in soil |

| ≥ 15 × cable overall diameter (recommended) | ≥ 0°C | ||||

Applications

Applications of A2XS(FL)2Y High Voltage Cables:

- Underground high-voltage power distribution networks

- Substations and large industrial plants

- Renewable energy: wind farms, photovoltaic power plants, energy storage systems

- Urban transmission lines and ring networks

- Power supply for airports, ports, mines, and large infrastructure projects

Compared to traditional copper-core high-voltage cables, the aluminum-core design offers a lightweight and cost-effective solution for long-distance high-voltage transmission, making it a worthwhile choice.

Typical Structure Specifications

| Voltage Rating Uo/U (kV) | Conductor Cross-section (mm²) | Conductor Class | Approx. Overall Diameter (mm) | Max. DC Resistance at 20°C (Ω/km) | Approx. Cable Weight (kg/km) | Current Rating in Ground (A) |

|---|---|---|---|---|---|---|

| 6/10 | 95 | Class 2 Al | 33 – 36 | 0.320 | 900 – 1,050 | 260 – 290 |

| 6/10 | 150 | Class 2 Al | 36 – 40 | 0.206 | 1,150 – 1,350 | 320 – 360 |

| 8.7/15 | 185 | Class 2 Al | 40 – 44 | 0.164 | 1,450 – 1,650 | 380 – 430 |

| 8.7/15 | 240 | Class 2 Al | 43 – 47 | 0.125 | 1,700 – 1,950 | 430 – 480 |

| 12/20 | 300 | Class 2 Al | 47 – 51 | 0.100 | 2,050 – 2,350 | 480 – 540 |

| 12/20 | 400 | Class 2 Al | 51 – 56 | 0.075 | 2,450 – 2,850 | 550 – 620 |

| 18/30 | 400 | Class 2 Al | 55 – 60 | 0.075 | 2,650 – 3,050 | 520 – 580 |

| 18/30 | 500 | Class 2 Al | 59 – 64 | 0.060 | 3,050 – 3,450 | 580 – 650 |

| 18/30 | 630 | Class 2 Al | 63 – 68 | 0.048 | 3,550 – 4,050 | 640 – 720 |

Note: The above data are typical values based on common IEC/VDE designs for A2XS(FL)2Y type high-voltage cables. Actual dimensions and rated current may vary slightly due to variations in the final design, installation conditions, and local standards. Detailed technical data sheets are available upon request for specific project requirements.

Advantages

Cost-Effective HV Solution – aluminium conductor reduces material cost while maintaining high current carrying capacity

Reliable Water-Blocking Design – longitudinal water-blocking elements limit water ingress and extend cable lifetime

Excellent Electrical Performance – XLPE insulation with low dielectric losses and high breakdown strength

High Mechanical Strength – PE outer sheath provides robust protection against mechanical impact and abrasion

Flexible Design Options – multiple voltage ratings and cross-sections available according to project requirements

Suitable for Direct Burial – robust PE sheath with water resistance and good environmental resistance

A2XS(FL)2Y vs A2XS2Y vs N2XS(FL)2Y

| Models | Conductor Material | Water-Blocking Structure | Sheath Material | Typical Uses |

| A2XS(FL)2Y | Aluminum (Al) | Longitudinal water-blocking (FL) | PE | Buried, long-distance, water-sensitive HV system |

| A2XS2Y | Aluminum (Al) | No or ordinary structure | PE | Standard HV underground/pipeline, dry environment |

| N2XS(FL)2Y | Copper Cu | Longitudinal water-blocking (FL) | PE | For scenarios with higher requirements for loss and voltage drop, heavy load |