1、High Voltage Cable Termination Structure and Insulation Mdium

1.1 Overall Structure

High-voltage cable terminations can be divided into porcelain sleeve type, composite sleeve type, integral prefabricated type, GIS termination, etc. Their core structure is similar. The description here is based on the ceramic sleeve type cable termination structure as an example.

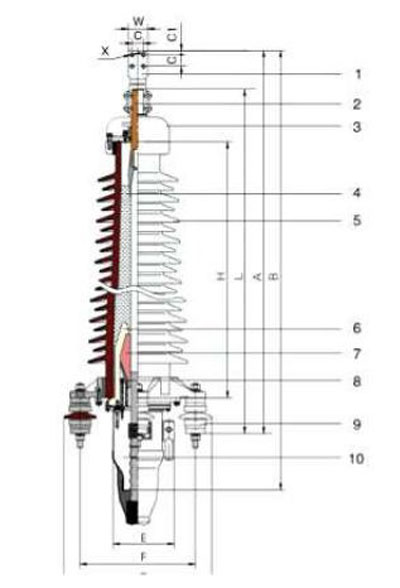

Figure 1 Typical structure of porcelain sleeve type cable termination

1—Outlet fittings, 2—Wiring post, 3—Shield cover, 4—Insulation filler, 5—Porcelain sleeve, 6—Stress cone protective cover, 7—Stress cone, 8—cone support, 9—support insulator, 10— Tailpipe

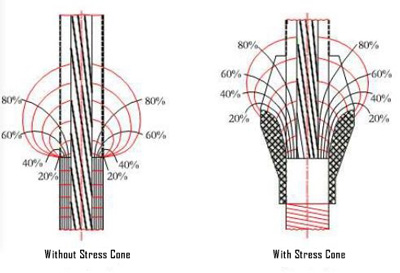

1.2 Stress Cone

The stress cone is the core part of the cable termination. After the cable body is stripped of the metal sheath and insulating shielding layer in the termination, there is not only an electric field component perpendicular to the length of the cable, but also an electric field component along the length of the cable, which is unevenly distributed. The edge of the metal sheath The electric field intensity is relatively concentrated. Therefore, it is necessary to use a stress cone to homogenize the electric field.

The stress cone is mainly composed of high-clarity semi-conductive materials, and a certain proportion of insulating materials will be added to enhance the bonding performance.

There are mainly two types of rubber stress cones used in cable terminations: one is to directly cover the rubber stress cone on the insulating part of the cable, and use the rubber elasticity of the stress cone material to maintain the mechanical stress and electrical strength of the stress cone and the insulation interface. The long-term high temperature and high pressure operating environment may cause the interface to age and relax, thereby reducing the electrical performance of the termination. The other is to install a spring compression device at the end of the stress cone, which can avoid the defects of the former. However, the structure is complex, and the manufacturing and installation requirements are higher. In practice, both of the above structures are used.

The outside of the stress cone is a stress cone, which plays a role of insulation. The color is white or beige, which can improve the pressure resistance level. It is composed of insulating materials such as EPDM rubber or silicone rubber.

1.3 Insulating Filler

Filling insulating agent generally uses silicone oil or polyisobutylene. The filling insulating agent should be compatible with the insulating materials and structural materials that are in contact. For ethylene-propylene rubber stress cones, it is recommended to use vacuum degassed low-viscosity silicone oil as an insulating filler. Polyisobutylene is recommended for silicone rubber stress cones. At the same time, high-viscosity silicone oil can also be used as an insulating filler.

Polyisobutylene synthetic insulating oil, which is a colorless or slightly yellow transparent liquid with good physical, chemical and dielectric properties. The dielectric loss does not increase at low temperatures, and the dielectric constant hardly changes with temperature. Silicone oil has stable chemical properties, high heat resistance, water resistance and excellent electrical insulation, which can inhibit the occurrence and diffusion of partial discharge to a certain extent.

2. Common Causes Of Fever And Corresponding Phenomena

Common causes of heating include aging of insulating oil, dampness of insulating oil, and deterioration of solid insulation.

2.1 The Insulating Oil is Aging or the Quality is Not Good Enough

After the insulating oil ages, the dielectric loss tgδ value of the insulating oil increases, and the heat generation increases, resulting in a temperature difference between the cable terminations. Partially mixed insulating oils may be stratified, and insulating oils with reduced performance after aging may be concentrated in one layer. It may result in agreeing to the temperature difference between different positions of the termination.

The aging of the insulating oil will affect its physical and chemical parameters: such as the increase of the dielectric loss tgδ, the decrease of the breakdown voltage, the increase of the acid value, and the smaller volume resistivity.

If the insulating oil itself is of poor quality and the dielectric loss constant is relatively large, it will also generate heat near the location of the stress cone where the electric field is the strongest.

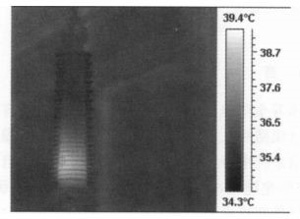

Figure 3 Infrared image when the dielectric loss of the silicone oil itself is large (the temperature difference between upper and lower is 2-4°) [Causes of heating of high-voltage cable porcelain sleeve termination]

2.2 Discharge Of Solid Insulating Medium

The internal solid insulation of the termination bushing is defective and causes partial discharge, which leads to local heating of the termination. The causes of partial discharge of solid insulation include aging of the insulation medium and poor installation.

The aging of the insulating medium leads to an increase in the dielectric loss of the solid insulation and an increase in heat generation. Poor installation may result in installation gaps in stress cones and other locations, resulting in partial discharges, which may cause temperature rise.

2.3 Moisture and water in the termination

When the termination is damp, the dielectric loss of the insulating oil increases and the heat generation increases. The electric field strength at the stress cone position is the largest, and the heat generation is most obvious. When the amount of water is large, the insulating oil will be stratified, and the water will be deposited in the lower layer. Due to the high moisture loss, the temperature of the lower part of the termination will rise.

When the insulating oil enters a large amount of water, the polyisobutylene has changed from transparent to yellow turbidity.

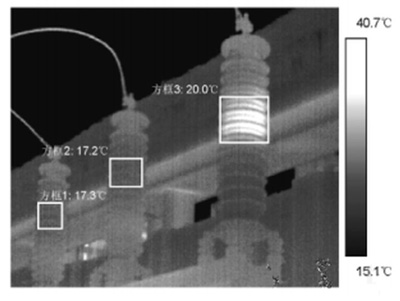

Figure 4 Typical heating image of water in the cable termination [Case analysis of abnormal heating of cable termination]

2.4 The External Insulation is Too Dirty

If the external insulation of the termination is too polluted, it may cause local creepage on the surface, and the energy generated by the discharge may cause local heating of the termination. At this time, in addition to the temperature rise in the infrared display of the termination, there will also be an audible discharge sound. Surface discharge can be detected with UV equipment.

3. Fever Analysis Method

3.1 Insulating Oil Detection

Take a sample of insulating oil to detect dielectric loss, breakdown voltage, volume resistivity, micro water, and oil chromatogram of the oil sample.

1) Use oil chromatography to check the discharge products in the oil to determine whether there has ever been a discharge inside.

The test method can refer to “GB/T 7252 Dissolved Gas Analysis and Judgment Guidelines in Transformer Oil”.

The judgment method can refer to 5.15.2.3 of “DL 393-2010-T Test Procedures for Condition Inspection and Maintenance of Power Transmission and Transformation Equipment”, “Analysis of Dissolved Gases in Oil. The content of each gas meets the following precautionary value requirements (uL/L): total combustible gas< 1500, H2<500: C2H2 trace amount, CO<100, C02<1000, cH4<200, C2H4<200: C2H6<200”.

2) Use micro water to determine whether the oil sample is damp.

There is currently no standard for the micro-water limit of the cable termination oil sample, but it can be judged whether it is damp by comparing the normal oil sample and the target oil sample.

3) Use dielectric loss, volume resistivity, and breakdown voltage to determine whether the oil sample is damp or deteriorated.

Refer to section 1.3 for judging standards for volume resistivity and breakdown voltage.

For the judgment of the dielectric loss value, please refer to 5.15.2.3 of “DL 393-2010-T Test Regulations for Condition Inspection of Power Transmission and Transformation Equipment”. “Under the test conditions of oil temperature (100+1)℃ and field strength of 1MV/m, for cables with Uo=190kV, it should not be greater than 0.01. For cables with U0≤127kV, it should not be greater than 0.03”

3.2 Partial Discharge Detection

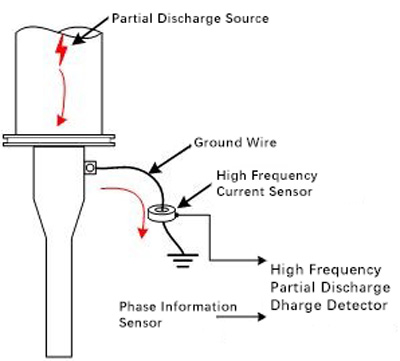

Use ultrasonic, high-frequency partial discharge and other methods to perform partial discharge detection on the termination, and judge whether there is internal discharge in the termination according to the detection map.

The test and judgment of the high-frequency partial discharge of the cable termination can be based on the “Q/GDW11400-2015 Electric Power Equipment High-frequency Partial Discharge Detection Technology Field Application Guide”.

Figure 5 Cable termination high-frequency partial discharge test wiring

3.3 Carry Out UV and Contamination Tests

Use the ultraviolet to determine whether there is discharge on the external surface of the termination, and use the pollution degree test to investigate the possibility of temperature rise caused by external pollution.

The pollution degree test is carried out in accordance with “Q/GDW 1152.1-2014 Power System Pollution Area Classification and External Insulation Selection Part 1: AC System”. After measuring the equivalent salt density and equivalent gray density, combined with the termination creepage distance, judge whether the corresponding pollution degree will cause the external insulation creepage.

4. Summary

1) The core of the cable termination is a stress cone, which controls the internal electric field strength. The material is generally ethylene propylene rubber or silicone rubber.

2) Cable termination insulating oil is generally low-viscosity silicone oil (with ethylene propylene rubber stress cone), polyisobutylene or high-viscosity silicone oil (with silicone rubber stress cone).

3) The common causes of heating of the termination are the aging of the insulating oil, the damp of the insulating oil, the deterioration of the solid insulation, and the excessive surface contamination.

4) When termination heating occurs, the insulating oil test can be used to investigate the possibility of moisture or deterioration of the insulating oil. Through the partial discharge test, investigate the possibility of internal discharge of the solid insulation. Through UV and pollution degree test, we can check the possibility of temperature rise caused by surface pollution.