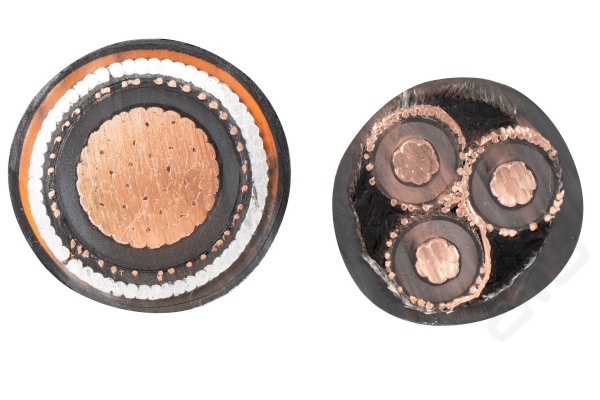

BS6622 standard is a popular British Standard for medium-voltage cables. It is commonly found in single- and three-core cable constructions with a voltage rating of 6.35/11 (12) kV. Due to their strong thermoplastic polyethylene(PE) sheath construction, BS6622 cables are chosen for ducting applications and cables when buried directly in the ground.

Table of Contents

ToggleBS 6622 Standard Construction

| Conductor | Class 2 stranded copper conductor |

| Conductor Screen | Semi-conductive XLPE |

| Insulation | XLPE |

| Insulation Screen | Semi-conductive XLPE |

| Separator | Water blocking tape |

| Insulation Screen | Semi-conductive XLPE |

| Metallic Screen | Individual copper wire screen |

| Bedding | PVC |

| Armour | SWA (Steel Wire Armoured) |

| Sheath | MDPE (Medium Density Polyethylene) & HDPE (High Density Polyethylene) |

BS 6622 Standard Cable Performance

Voltage Rating: 6.35/11kV – Tested to Voltage and Duration of BS 6622

Operating Temperature: -15°C up to 90°C

Temperature Range: -5°C ( PVC or LSZH sheath ); -20°C ( PE sheath )

Short Circuit Temperature: 250°C (short circuit duration up to 5 seconds)

Bending Radius: 12 x OD

BS 6622 Standard Cable Application

The BS6622 standard is ideally suited to electrical engineering applications. Because this standard often uses polyethylene(PE) as the cable sheath material, the advantages are particularly significant in applications requiring high insulation, chemical resistance, and long periods of outdoor use, where the polyethylene sheath provides excellent protection.

Medium Voltage Distribution Systems for Commercial Buildings

– In industrial, commercial and large building complexes, BS6622 cables are commonly used in medium-voltage power distribution networks from the substation to the customer’s end.

– This includes underground distribution, cable trench wiring and buried laying to ensure stable power distribution.

Infrastructure & Transportation Engineering

– It is applied in key infrastructure projects such as railroads, subways, airports, ports, etc. to meet the requirements of mechanical strength and weather resistance in long-term operation.

– It is also suitable for medium voltage power supply lines on both sides of highways and city roads, supporting the construction of modern urban infrastructure.

Energy and Renewable Energy Sector

– In renewable energy projects such as wind and solar power, BS 6622 is used to connect power generation equipment, substations and power grids to ensure safety and efficiency during energy conversion and transmission.

– At the same time PE sheathing can withstand offshore or outdoor harsh environments due to its good chemical and weather resistance.

BS 6622 Standard Specifications

| SINGLE CORE | ||||||||

| NO. of Cores | Nominal Cross Section mm² | Min. thickness mm | Nominal Thickness of Semiconductive Layer mm | Common Diameter mm | Nomial Weight kg/km | |||

| Insulation | Outer sheath | Inner | Outer | Over insulation | Overal | |||

| 1 | 50 | 395 | 1.32 | 0.5 | 0.8 | 19.5 | 29 | 1400 |

| 1 | 70 | 395 | 1.4 | 0.5 | 0.8 | 21.1 | 31 | 1700 |

| 1 | 95 | 395 | 1.48 | 0.5 | 0.8 | 2280 | 34 | 2100 |

| 1 | 120 | 3.95 | 1.48 | 0.5 | 0.8 | 24.1 | 35 | 2350 |

| 1 | 150 | 3.95 | 1.56 | 0.5 | 0.8 | 26 | 37 | 2700 |

| 1 | 185 | 3.95 | 1.56 | 0.5 | 0.8 | 27.3 | 39 | 3200 |

| 1 | 240 | 3.95 | 1.64 | 0.5 | 0.8 | 30 | 42 | 3750 |

| 1 | 300 | 3.95 | 1.72 | 0.5 | 0.8 | 32.1 | 45 | 4600 |

| 1 | 400 | 3.95 | 1.8 | 0.5 | 0.8 | 35 | 48 | 5500 |

| 1 | 500 | 3.95 | 1.88 | 0.5 | 0.8 | 38 | 51 | 6750 |

| 1 | 630 | 3.95 | 1.96 | 0.5 | 0.8 | 42.1 | 56 | 8200 |

| THREE CORES | ||||||||

| NO. of Cores | Nominal Cross Section mm² | Min. thickness mm | Nominal Thickness of Semiconductive Layer mm | Common Diameter mm | Nomial Weight kg/km | |||

| Insulation | Outer sheath | Inner | Outer | Over insulation | Overall | |||

| 3 | 50 | 3.95 | 2.12 | 0.5 | 0.8 | 19.5 | 57 | 5500 |

| 3 | 70 | 3.95 | 2.2 | 0.5 | 0.8 | 21.1 | 61 | 6500 |

| 3 | 95 | 3.95 | 2.28 | 0.5 | 0.8 | 22.8 | 65 | 7600 |

| 3 | 120 | 3.95 | 2.36 | 0.5 | 0.8 | 24.1 | 68 | 8600 |

| 3 | 150 | 3.95 | 2.52 | 0.5 | 0.8 | 26 | 74 | 10500 |

| 3 | 185 | 3.95 | 2.6 | 0.5 | 0.8 | 27.3 | 77 | 11900 |

| 3 | 240 | 3.95 | 2.76 | 0.5 | 0.8 | 30 | 83 | 14200 |

| 3 | 300 | 3.95 | 2.84 | 0.5 | 0.8 | 32.1 | 88 | 16600 |

| 3 | 400 | 3.95 | 3.08 | 0.5 | 0.8 | 35 | 95 | 19700 |

| 3 | 500 | 3.95 | 3.24 | 0.5 | 0.8 | 38 | 103 | 23600 |

Advantages - ZMS Cable BS6622 Standard

Excellent Insulation Properties

The polyethylene sheath material used in BS6622 standard cables has high dielectric strength, which can effectively isolate the current and ensure that the cable maintains stable electrical performance under various working conditions.

Low Water Absorption

Low water absorption, even in humid environments can maintain good electrical insulation properties, reducing the impact of moisture on the performance of the cable.

Good Chemical Resistance

Polyethylene is resistant to most acids, alkalis, and salts, and is suitable for cable applications in a wide range of chemical environments and harsh working conditions.

Weatherability & UV Resistance

With the appropriate addition of UV-resistant agents, the polyethylene sheath is resistant to the effects of direct sunlight and other natural environmental factors, and is suitable for outdoor use for a long time.

Good Quality & Low Price

The relatively low processing cost of this standard cable makes it an economical and practical cable choice.