BS 6724 LSZH 0.6/1kV cable is a low-smoke, halogen-free, flame-retardant power and control cable designed for fixed installation environments where fire safety, smoke emissions, and toxic gas emissions must be minimized. Manufactured to BS 6724 and BASEC certification standards, this cable is widely used in commercial, industrial, and public buildings requiring enhanced fire resistance and reliable electrical performance.

Table of Contents

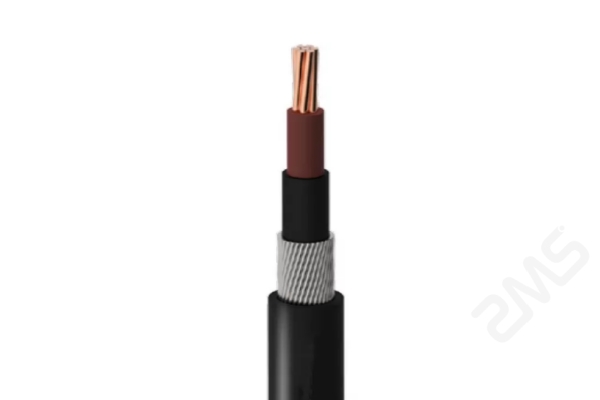

ToggleLSZH 0.6/1kV Cable Structure

Conductor: formed to Class 2 stranded construction

- Excellent electrical conductivity

- Reduced DC resistance

- Improved flexibility for installation in fixed systems

- Stable current-carrying performance under continuous load

Insulation: XLPE (Cross-Linked Polyethylene)

- XLPE ensures that the conductor remains electrically isolated even in demanding industrial environments.

Bedding Layer: LSZH Compound

- A mechanical separator between armour wires and insulation

- A cushion that absorbs mechanical stress and prevents armour penetration

Armour Layer:

- Aluminium Wire Armour (AWA) for single-core cables

- Steel Wire Armour (SWA) for multi-core versions

Construction Parameters (Typical Values)

| Cross Section (mm²) | Conductor Stranding (No./mm) | Insulation Thickness (mm) | Bedding Thickness (mm) | Armour Diameter (mm approx.) | Overall Diameter (mm) | Approx. Weight (kg/km) |

| 16 | 7/1.70 | 0.7 | 1.2 | 14.5 | 17–18 | 420 |

| 25 | 7/2.14 | 0.9 | 1.3 | 16.5 | 19–20 | 520 |

| 35 | 7/2.52 | 0.9 | 1.3 | 18 | 21–22 | 620 |

| 50 | 19/1.78 | 1 | 1.4 | 20 | 23–24 | 770 |

| 70 | 19/2.14 | 1.1 | 1.5 | 23 | 26–27 | 1030 |

| 95 | 19/2.52 | 1.1 | 1.6 | 26 | 29–30 | 1290 |

| 120 | 37/2.14 | 1.2 | 1.7 | 28.5 | 31–32 | 1550 |

| 150 | 37/2.52 | 1.4 | 1.8 | 31 | 34–35 | 1850 |

| 185 | 37/2.85 | 1.6 | 2 | 34 | 37–38 | 2200 |

| 240 | 61/2.52 | 1.7 | 2.2 | 38 | 41–42 | 2800 |

| 300 | 61/2.85 | 1.8 | 2.3 | 42 | 45–46 | 3400 |

Note: This data represents typical industry standards and applies to most products, but should not be considered an absolute value. Please contact us if you require other structural specifications!

Electrical Characteristics (Typical Values)

| Cross Section (mm2) | Conductor Class | Max. DC Resistance (Ω/km at 20°C) | Current Rating in Air (A) | Current Rating in Ground (A) | Voltage Drop (mV/A·m) |

| 16 | Class 2 | 1.15 | 94 | 76 | 2.8 |

| 25 | Class 2 | 0.727 | 125 | 99 | 1.75 |

| 35 | Class 2 | 0.524 | 154 | 119 | 1.25 |

| 50 | Class 2 | 0.387 | 187 | 143 | 1 |

| 70 | Class 2 | 0.268 | 233 | 179 | 0.7 |

| 95 | Class 2 | 0.193 | 285 | 217 | 0.5 |

| 120 | Class 2 | 0.153 | 328 | 249 | 0.4 |

| 150 | Class 2 | 0.124 | 376 | 282 | 0.35 |

| 185 | Class 2 | 0.0991 | 427 | 320 | 0.32 |

| 240 | Class 2 | 0.0754 | 502 | 365 | 0.27 |

| 300 | Class 2 | 0.0601 | 573 | 414 | 0.24 |

Note: This data represents typical industry standards and applies to most products, but should not be considered an absolute value. Please contact us if you require other technical specifications!

Applications

- Power and auxiliary fixed cabling in industrial applications;

- Indoor and outdoor installations such as cable ducts, trunking, and building equipment requiring low-smoke halogen-free materials;

- High fire risk areas: public buildings, transportation hubs, hospitals, schools;

- Industrial environments require flame-retardant and UV-resistant properties.