IEC 60228 Cable

IEC 60228 cables cover a variety of cable cross-sectional areas, specifying the conductor resistance values for types such as solid stranded copper conductors, aluminum conductors, aluminum alloy conductors, and flexible copper conductors.

As a professional IEC 60228 cable supplier, ZMS utilizes these standards skillfully, including the rapid conversion between different cross-sectional area units, to supply customers with safe and suitable standard cables.

Cable Products Meeting IEC 60228

The IEC 60228 standard regulates the various types of flexible wires (nominal cross-section from 0.5 mm² to 2500 mm) or conductors in the cable classification, which relates to quantity specifications and resistance values of individual wires. Such conductors include solid and stranded copper, aluminum, and aluminum alloy conductors in fixed-laying cables, as well as soft copper conductors. And the standard does not cover communication cables.

NOTE: Unless otherwise specified in the relevant clause, this standard deals only with conductors in finished cables and does not deal with conductors in the course of manufacture and procurement that are intended for use in cables.

IEC 60228 Solid Conductor

- Solid conductors are made of bare annealed copper, aluminum, or aluminum alloy wire material.

- Solid copper conductors shall be of circular cross-section. Solid copper conductors with a nominal cross-section of 25 mm and above are only suitable for special cables (e.g. mineral insulated cables) and are not suitable for general-purpose cables.

- Solid aluminum conductors and solid aluminum alloy conductors with a standard cross-section of 10 mm to 35 mm shall be of circular cross-section. Conductors with a larger standard cross-section shall be of circular cross-section if used in a single cable larger conductors, if used for single-core cables shall be circular cross-sections; if used for multi-core cables can be circular cross-sections, and can also be molded cross-sections.

Stranded Non-Crimped Round Conductors

Stranded non-tightened round conductors consist of fire copper, aluminum or aluminum alloy wire material.

Stranded aluminum or aluminum alloy conductors shall have a cross-section of not less than 10 mm.

The nominal diameter of the individual wires in each conductor shall be the same.

The number of individual wires in each conductor shall be not less than the corresponding minimum number specified.

1. Electron beam cross-linked materials do not melt or flow, even at high temperatures, with high resistance against heat, cold, abrasion, UV, ozone, and hydrolyses.

2. These cables provide the means to interconnect between photovoltaic(PV) panels and from panels to the inverter.

3. They operate at DC voltage and provide long life in exposed conditions.

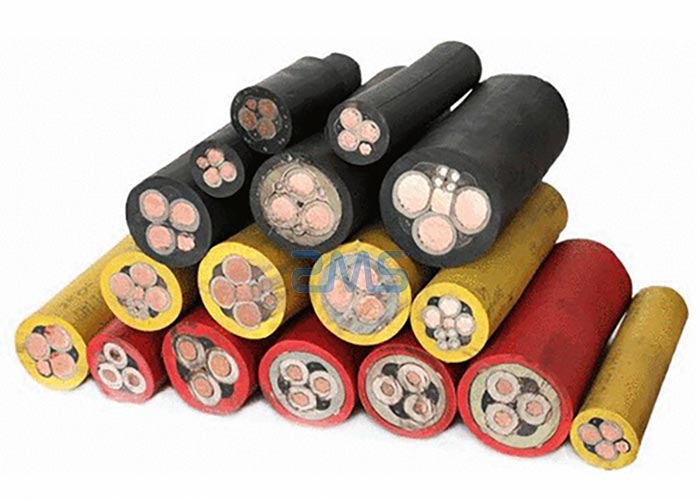

Heavy-duty tough rubber flexible cable with or without individually earth-screened cores for dynamic or static applications in aggressive environments. Flame retardant, abrasion, cut, notch and tear-resistant. Good resistance to oil and fats. Suitable for installation in dry, damp, wet, and in hazardous environments. For power supplies where high levels of mechanical stress and abrasion are expected. Can be permanently submersed in fresh water, salt water, stormwater, oily water, and sewage-contaminated water to a depth of 100 meters. Suitable for indoor and outdoor applications.

- Copper or aluminum core XLPE insulated thin steel wire armored PVC sheathed power cables.

- Copper or aluminum core XLPE insulated thin steel wire armored polyethylene sheathed power cables.

- Copper or Aluminum Core XLPE Insulated Thin Steel Wire Sheathed PVC Sheathed Power Cable.

- Copper or aluminum core XLPE insulated thin steel wire armored polyethylene sheathed power cables.

For the supply of electricity in low-voltage installations, suitable for installation indoors and outdoors, in cable ducts, underground, in power stations and switching stations, in local energy distribution, and in industrial plants, where there is no risk of mechanical damage.

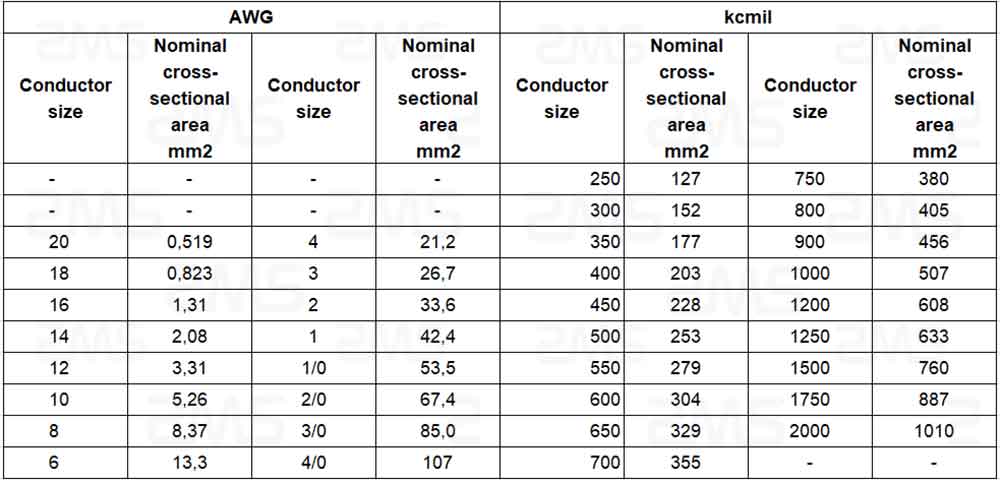

IEC 60228 Cable Specification

The conductors described in IEC 60228 are specified in metric sizes. The sizes and characteristics of conductors currently used are based on the American Wire Gauge (AWG) system, with kcmil used for larger sizes. The use of these sizes is currently specified uniformly. IEC TC 20 cable product standard does not specify the use of AWG/kcmil conductors for cables. ZMS Cable is a leading manufacturer of high-quality cables for a wide range of applications. Our products comply with various international standards, including IEC60502, IEC60228, IEC60332, IEC60840, etc. Our state-of-the-art production facilities and a team of skilled engineers and technicians enable us to produce cables that meet the highest standards of performance and durability.

IEC 60228 Cable Class

IEC 60228 is a widely recognized cable conductor standard that specifies the requirements for various types of conductors, categorized into classes 1, 2, 5, and others, based on their flexibility, as illustrated below.

This guide explores the flexibility of the body and its thermal effect, specifically temperature.

IEC 60228 cable class 1: solid conductor.

IEC 60228 cable class 2: stranded conductors for fixed installations.

IEC 60228 cable class 5: flexible conductors.

IEC 60228 cable class 6: very flexible conductors.

The standard IEC 60228 covers solid and stranded copper, aluminum, and aluminum alloy conductors, and flexible copper conductors in fixed installation cables. This standard does not apply to conductors used for telecommunication purposes.

FAQ

What is the difference between Class 2 and Class 5 conductor?

Are IEC 60228 cables and BS EN 60228 the same standard?

Where can I obtain the PDF file of the IEC 60228 standard?

ZMS Cable Service

Wide Cable Product Range

As a professional cable manufacturer and exporter, ZMS supplies a complete range of power cables, control cables, instrument cables, and conductors for global industrial projects.

International Standards & Custom Production

Products are manufactured according to IEC, BS, ASTM, DIN, GB, and other standards, with custom cable design available based on technical requirements.

Professional Technical Support

Free pre-sales consultation, product selection guidance, and one-to-one project solution support for different application environments.

Reliable Delivery Solutions

Optimized packaging and shipping plans to ensure safe delivery while helping reduce transportation risks and costs.

Export Packaging Protection

Wooden drums, cartons, or coils packaging with moisture-proof sealed cable ends and waterproof markings for international transport.