Deep Sea Cable Solutions

As a professional cable exporter, ZMS Cable is committed to providing Deep Sea Cable Solutions for the world’s major offshore and submarine projects, our products not only cover traditional power transmission cables, but also extend to high-tech undersea fiber optics, deep-sea high-voltage cables, etc., to meet the needs of many countries and regions for a wide range of applications, such as oil and gas, offshore wind, submarine communications and scientific research projects. and scientific research projects in many countries and regions.

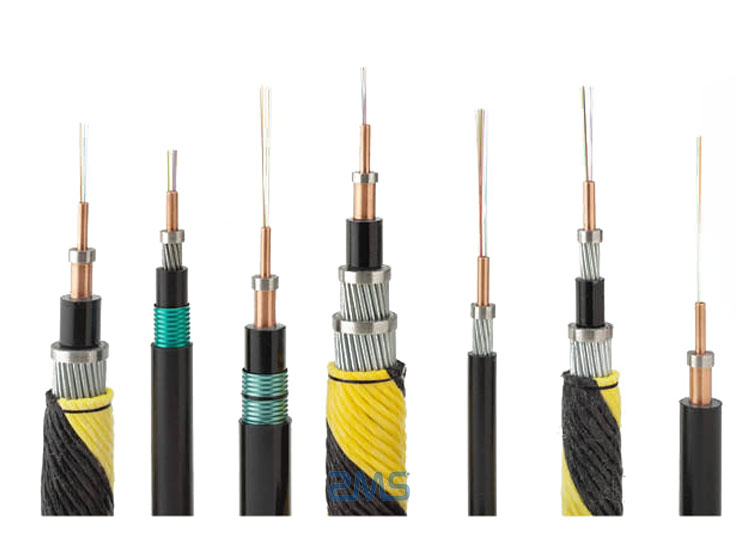

ZMS Underwater Sea Cable Products

As a professional manufacturer of underground sea cables, we have a series of mature underwater sea cables products, which can meet the different needs of different customer projects:

High Voltage Submarine Power Cable

Features: It adopts advanced pressure-resistant materials and a multi-layer protection structure, which provides excellent resistance to seawater erosion and mechanical protection.

Application Areas: offshore wind power, deep-sea oil and gas platforms, offshore power stations.

| Conductor | Copper (Cu) or Aluminum (Al) |

| Tightly compressed stranded or split conductors to minimize skin effect and improve electrical conductivity | |

| Efficient transmission of electrical energy, ensuring low losses and high conductivity | |

| Conductor Screen | Semi-conductive materials (extruded or wrapped) |

| Reduces electric field stress, ensures electric field uniformity, and improves cable voltage resistance | |

| Insulation | Cross-linked polyethylene (XLPE), ethylene propylene rubber (EPR), etc. |

| Provides high electrical insulation to prevent electrical breakdowns | |

| Insulation Screen | Semi-conductive materials (extruded or wrapped) |

| Uniform electric field, reduce partial discharge, improve the long-term stability of cable operation | |

| Metallic Screen | Copper wire shielding or copper tape wrapping |

| Shields against electromagnetic interference and provides some mechanical protection | |

| Inner Sheath & Fillers | Polyethylene (PE), polyvinyl chloride (PVC) or thermoset materials |

| Maintains structural stability of cables and enhances mechanical strength | |

| Armour | Single or double galvanized steel wire/strip/aluminum wire |

| Provides resistance to tension, impact and marine life damage and improves cable crush resistance | |

| Outer Sheath | Polyethylene (PE), polyurethane (PU) or seawater corrosion resistant materials |

| Prevents mechanical damage, resistant to UV rays and salt spray corrosion, extends cable life |

Undersea Fiber Optic Communication Cable

Features: High-performance optical fiber and waterproof and pressure-resistant design to achieve long-distance, low-loss signal transmission.

Application Areas: international submarine communication network, transoceanic data center, remote monitoring system.

| Optical Fiber Unit | Used for high-speed data transmission, usually single-mode fiber. |

| Loose Tube | Filled with waterproof grease to protect the fiber from moisture and mechanical stress. |

| Water Blocking Layer | Consists of intumescent powder or waterproof tape to prevent moisture penetration. |

| Inner Sheath | Polyethylene (PE) is usually used for enhanced mechanical protection and corrosion resistance. |

| Metallic Armour | Galvanized steel wire armoring to improve tensile strength and pressure resistance and prevent damage from marine life. |

| Outer Sheath | Made of polyethylene (PE) or polyurethane (PU) to provide additional weathering and protection. |

| Power Conductors | Copper or aluminum conductors to power relay amplifiers and support long distance signal transmission. |

Multifunctional Submarine Integrated Cable

Features: power transmission and data communication in one to meet the needs of comprehensive applications at sea.

Application Areas: marine scientific research, offshore platform integrated wiring, intelligent monitoring.

| Conductor | Copper or aluminum conductors for power transmission. |

| Optical Fiber Unit | Integrated fiber optics for data communication and remote monitoring. |

| Insulation | Cross-linked polyethylene (XLPE) or ethylene propylene rubber (EPR) is used to provide electrical insulation. |

| Shielding Layer | Semi-conductive material or metal shielding to reduce electromagnetic interference. |

| Filler | Waterproofing material that stabilizes the structure and prevents moisture penetration. |

| Inner Sheath | Polyethylene (PE) or polyvinyl chloride (PVC) to protect the internal structure. |

| Armour Layer | Galvanized steel wires or strips for improved tensile strength and pressure resistance. |

| Outer Sheath | Polyethylene (PE) or polyurethane (PU) for waterproof, corrosion and abrasion protection. |

Customized Special Environment Cables

Features: Customized design according to customers’ needs, suitable for extreme deep sea, high salinity, and complex environment.

Application Areas: marine environment monitoring, deep sea exploration, and special engineering projects.

| Conductor | High purity copper or silver plated copper for improved conductivity and corrosion resistance. |

| Insulation | XLPE, EPR or specialty polymers ensure high voltage insulation. |

| Shielding Layer | Metal braided or aluminum foil shielding to prevent electromagnetic interference. |

| Optical Fiber Unit | Integrated fiber optics to support data transmission and remote monitoring. |

| Filler | Waterproof material to enhance cable stability and prevent moisture penetration. |

| Inner Sheath | Oil, cold and salt spray resistant materials to improve mechanical strength. |

| Armour Layer | High-strength steel wire or Kevlar fibers for improved pressure and tensile resistance. |

| Outer Sheath | Polyurethane (PU) or fluoroplastic for corrosion, abrasion, and bio-erosion protection. |

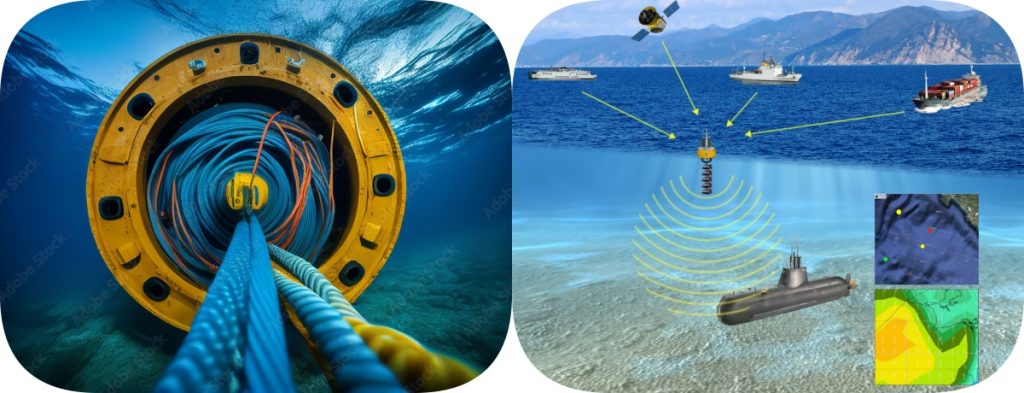

Success Stories: Offshore and Subsea Project Supply

With rich project experience and strict quality management, ZMS Cable has provided stable and efficient Deep Sea Cable Solutions for many famous domestic and international offshore and submarine projects. including:

China Offshore Wind Farm Project

Provided customized under sea cabling solutions for many coastal and offshore wind farms in China, with fast delivery of offshore wind power cables and turbine accessories, etc., to ensure efficient power transmission and resistance to harsh marine environments, meeting the high standards of “Deep Sea Cable Solutions for offshore wind farms”. The high “Deep Sea Cable Solutions for offshore wind farms” standard is met.

Middle East Deep Sea Oil & Gas Exploration & development

In the deep-sea oil and gas platform projects in the Middle East, ZMS provides high-voltage, high-security armored underwater cable to help deep-sea oil and gas exploration, exploitation, and transportation, truly realizing the “submarine cable solutions for deep-sea applications”. The perfect presentation of “submarine cable solutions for deep-sea applications” is truly realized.

Submarine Communications & Data Transmission Engineering

In response to the comprehensive development of international submarine communication networks, ZMS supplies high-quality drop cables to ensure high-speed global information interconnection, realizing the goal of “underwater cable systems for global connectivity”.

Marine Scientific Research & Environmental Monitoring Program

There are many marine research institutes and environmental monitoring projects around the world that continue to contribute to the development of marine energy. ZMS provides stable and reliable submarine cable communication solutions for these projects, and the interconnection of these cables perfectly realizes all kinds of marine data collection and transmission, which is a breakthrough in both science and environmental protection.

Technical Advantages & Service Commitment

Each of our Deep Sea Cable Solutions products has been rigorously designed, tested, and quality certified to provide the following benefits:

- International Standard Certification

Our products comply with international standards such as ISO and IEC to ensure safe and stable operation. - Customized Solutions

According to different offshore and submarine project requirements, we provide personalized design and technical support to achieve the best transmission efficiency. - Advanced Manufacturing Process

The adoption of advanced production equipment and an automated inspection system ensures that each submarine cable is highly resistant to pressure, abrasion, and corrosion. - Global Flow & After-Sales Service

We have established a perfect global logistics system and professional after-sales team to ensure that our customers receive timely and professional support during the whole process of procurement, installation, and use. - R&D and Innovation Drive

Continuously investing in R&D, we keep launching deep sea cable products adapted to the new demands of the market, providing customers with cutting-edge Deep Sea Cable Solutions.

Contact Us

If you are looking for international standard Deep Sea Cable Solutions for your project, whether it is for offshore wind, oil and gas development, subsea communications or scientific monitoring, ZMS is the right partner for you.

Please feel free to contact us for more information on our products and customized services.