In recent years, there are two main types of fiber optic cables laid in the power system, ADSS, and OPGW. Among them, ADSS fiber optic cable is welcomed by users for its lightweight, easy construction, and can make full use of the existing tower system, etc. It is developing faster. ZMS Cable Company is committed to leading the market in fiber optic cable technology and has conducted a lot of experiments to verify the design and production of fiber optic cable.

1. External Conditions Affecting The Design of ADSS Fiber Optic Cable

ADSS cable design needs to fully consider the climate conditions of the cable laying site. Therefore, three basic parameters are essential in the design of fiber optic cable. These three parameters are the local ice thickness, wind speed, and temperature. Of course, the tower line condition of the laying site is also one of the important factors affecting the design. Specific analysis of the specific situation is required.

1.1 Load

The fiber optic cable is suspended from the tower and is affected by the environment, and the force W on the cable is a combined force in the horizontal and vertical directions. In the horizontal direction, the fiber optic cable is affected by the wind pressure and has a horizontal component force of W1. In the vertical direction, the force on the fiber optic cable is composed of two parts. One is the self-weight of the fiber optic cable itself W2, and the other is the weight of the ice covering the surface of the cable W3. In addition, to ensure the safety of the fiber optic cable operation, the safety factor is taken in its vertical direction. That is the unit length of the force Ws.

1.2 Spans and Arc Sag

When the meteorological conditions of the fiber optic cable are determined, it can be designed according to the span and number of cores required by the customer.ADSS fiber optic cable has two ways of equal height and unequal height erection.

The span and installation sag of the cable are the main factors that determine the tension of the ADSS cable. When the span and installation pitch change, the tension of the ADSS cable also changes accordingly. The installation tension of fiber optic cable depends on the initial arc pitch of the cable and the weight of the cable itself.

Among them, the worst arc sag of the cable can be introduced from the length of the cable. Because in the same span, no matter how the arc sag of the cable changes, the length of the cable is constant. According to this principle, the worst arc sag of fiber optic cable can be introduced.

1.3 Other factors

One of the strengthening elements of ADSS fiber optic cable is aramid, the coefficient of thermal expansion of aramid is negative, that is, the temperature rises aramid shrinkage, and vice versa. The coefficient of linear expansion of the other parts of the cable is positive. After taking into account, the coefficient of linear expansion of the entire cable is not large. Therefore, the temperature change on the ADSS cable is not as big as the impact of ordinary optical fiber cable.

ADSS fiber optic cable is in strong electric field conditions, the sheath surface will appear galvanic corrosion phenomenon. For this phenomenon, when the field voltage is greater than 12KV, or less than 25KV, the cable sheath uses anti-electrolysis materials.

2. Fiber optic cable design

ZMS provides ADSS fiber optic cable under the maximum load conditions, and the strain of the fiber is zero. The zero-strain design of the fiber depends on two factors: the residual length of the fiber in the loose casing and the casing stranding pitch.

2.1 Casing residual length

In the loose casing design, the optical fiber is located in a loose casing filled with grease. Since the outer diameter of the casing is much larger than the outer diameter of the fiber, the fiber can move freely in the loose casing. This ensures that the fiber has a certain margin of space when the cable is under tension.

The residual length of the fiber and its free movement in the loose casing allows the fiber to remain in a stress-free state when the cable is elongated and contracted.ADSS fiber optic cable installation, extremely high temperatures, and maximum load will subject the cable to elongation. The reason for the contraction of the cable is the tendency of the fiber optic cable elements to shrink at very low temperatures. Therefore, the design of the residual length in the casing is very demanding, the residual length is too long, the cable shrinkage will be a problem. The residual length is too small, the fiber optic cable elongation is also easy to not meet.

2.2 Casing stranding pitch

In the design of the loose jacket structure, the casing is arranged in a stranded manner around the central reinforcement, and the diameter and stranded pitch of the central reinforcement provide the fiber stranding margin relative to the cable. Under normal conditions, the fiber is located approximately at the center of the casing.

In a loose casing structure, the conditions that determine the fiber strain are the choice of fiber optic cable material and the design of the fiber optic cable structure.

2.3 Fiber optic cable material

The selection of an appropriate fiber optic cable material with a sufficiently high modulus and low coefficient of expansion and creep can limit the strain during elongation and contraction of the fiber optic cable. The modulus of the material directly corresponds to the strength of the material, and the coefficient of linear expansion directly reflects the change of the material at extreme temperatures. Therefore, materials with both high modulus of elasticity and low coefficient of linear expansion have good stability in high strength and at high and low-temperature extremes. The choice of material includes the type and amount of plastic and fiber optic cable reinforcement material. The fiber optic cable is precisely designed and manufactured to ensure that there is sufficient slack in the cable to meet the strain on the fiber within the maximum load and operating temperature. As the main reinforcing element of the fiber optic cable, aramid has a high modulus of elasticity, low creep, low expansion coefficient, and other characteristics, so it is widely used in the production of ADSS fiber optic cable.

2.4 Fiber optic cable structure

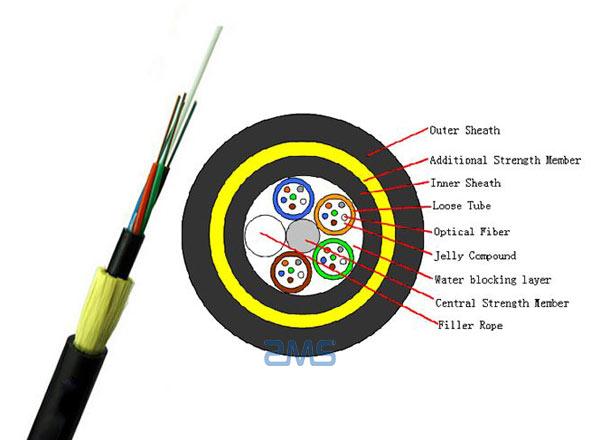

The design parameters of fiber optic cable include the size of the components (central reinforcement and loose tube), the stranded length, and the number of fibers per tube. The center reinforcement provides tensile strength and resistance to deformation when the cable is in a low-temperature environment. Specifically, the center reinforcement has two functions. One is the tensile strength when the cable is under stress, and the other is the shrinkage resistance of the plastic in the cable when it shrinks at low temperatures. The design of the loose casing has a decisive role in the reliability of the fiber optic cable. The proper casing inner diameter can ensure that the fiber has enough space to move. The outer diameter of the casing is to ensure that it remains stable under mechanical stress, such as flattening, bending, and twisting. Casing strand pitch is to ensure that when the fiber optic cable is under tension there is enough fiber length, but also to meet the bending strain of the fiber.

In the actual application of ADSS fiber optic cable, ADSS fiber optic cable is fixed on the tower by the special metal, so the cooperation between the fiber optic cable and the metal is very important, if the metal and fiber optic cable with bad, the performance of the fiber optic cable can not reflect the design requirements, and even damage to the cable. In conjunction with the use of gold, the design of the outer sheath of ADSS cable is also a key factor, the thickness of the outer sheath should not be too thick. The thickness is too thick on the fiber optic cable caused by two points. First, when the cable encounters high temperature, the sheath is easy to become soft, between the cable and the fixture caused by slippage. Second, the thickness of the cable sheath is too large, and the grip of the cable is not easy to reach the internal components of the cable, which may cause the relative slippage of the cable components. Therefore, through research and testing, we believe that the outer sheath thickness of 1.5 mm is more reasonable.

In addition, in the design of the ADSS cable core structure, we use the dry water-blocking method, instead of the traditional filling oil paste type water blocking. The advantage of dry water-blocking is: because there is no cable paste, the cable weight is light and more suitable for ADSS cable operation. Water blocking material and other materials of optical cable have better compatibility. The production process and process are relatively simple. More convenient for the installation and jointing of fiber optic cable.

3. Concluding Remarks

Ensuring the normal operation and long-term reliability of the mechanical strength of ADSS fiber optic cable is the subject of our long-term research and development. In the design research of ADSS, we will combine the advanced materials and equipment to provide the most reasonable solution for our customers.