Cold Shrink Cable Termination

Cold shrink cable terminations adopt advanced cold shrink technology. No need to use an open flame and special tools during installation, just gently extract the core rope. Grounding adopts a constant force spring, no welding or copper wire binding is required. The cold shrinkable cable termination is more time-saving, labor-saving, and space-saving.

- Professional cold-shrinkage technology, one-piece design, easy to install, and applicable to different cable cross-sections.

- No silicone grease is applied during installation, which reduces the probability of dirty flash.

Kind of the Cold Shrink Cable Termination

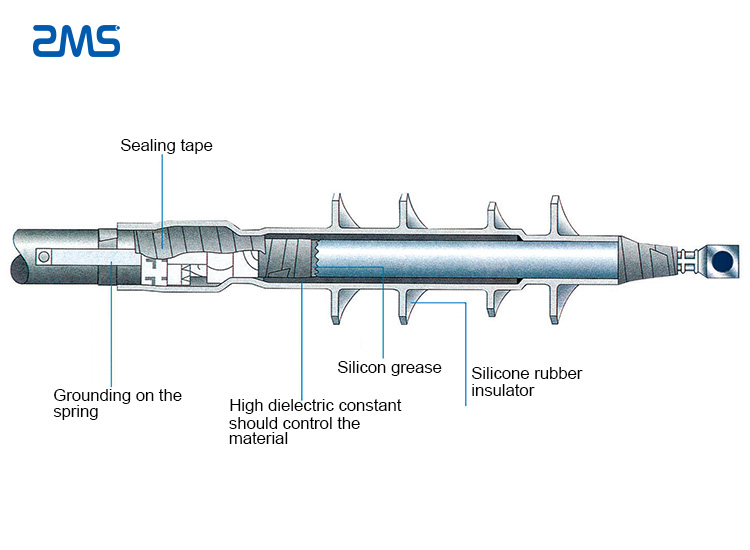

8.7/15kv Cold Shrink Cable Termination (Second Generation)

- Adopting unique cold shrinking technology, no special training is required during installation, and no need to push hard, open flame and use special tools, you only need to extract the core rope.

- One model is suitable for a variety of cable diameters; the single-piece compact design reduces the space distance

- The use of high-quality silicone rubber material has strong anti-tracking and corrosion resistance, excellent electrical performance and long service life.

- High dielectric constant stress control can reduce surface electrical stress.

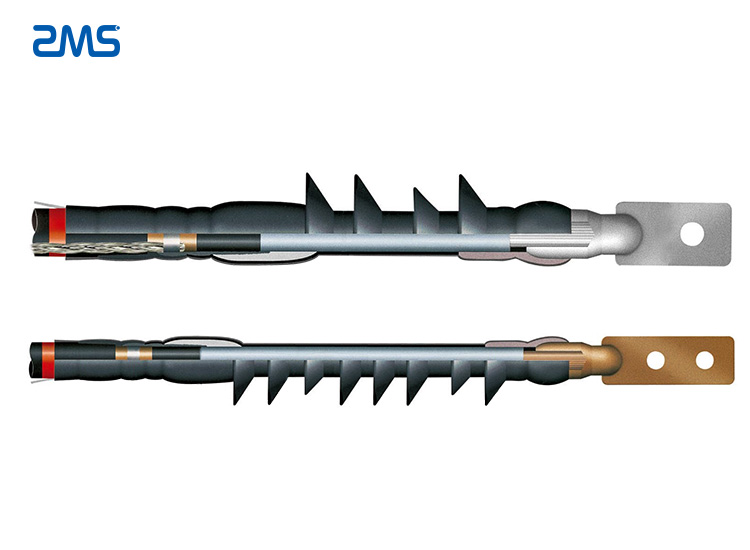

Single Core Rubber-Plastic Insulated Termination

Three-Core Rubber-Plastic Insulated Termination

15kv/35kv Cold Shrink Cable Termination (Third Generation)

- The new third-generation cable termination has a breakthrough in materials and design. While maintaining the advantages of the second-generation product, it has the advantages of smaller body size, faster installation, and more stable performance.

- One-piece fully equipped design, installation in one step, no need to apply silicone grease, no need to wrap tape, the cable termination can be connected in one step.

- All-round super-strength material improvement, the three indexes of anti-tracking, corrosion resistance, and hydrophobicity are comprehensively increased by four times, and the operating life is greatly extended.

Multi-Level Voltage Standards, Wider Application Range

- Indoor termination no skirt design: the highest voltage level is 15kv

- Outdoor termination four skirt design: the highest voltage level is 20kv

- Indoor and outdoor termination Eight skirt design: the highest voltage level is 30kv

Types of the Cold Shrink Cable Joint

15kv Cold Shrink Cable Terminal Joint

- It has reliable performance and an overall prefabricated compact design. Liquid silicone rubber material, good insulation performance, resistance to electric tracking, high temperature and acid and alkali resistance.

- It has a constant contraction force and does not cause insulation dead angles due to cable bending.

- One type of cable termination connector adapts to multiple cable diameters. The construction and operation ability will not be affected in the low temperature environment. At the same time, it can be used for transition joints and conversion joints.

- It adopts cold shrinkage technology and is easy to install without special tools. Each set of intermediate joints is individually packaged and comes with installation instructions.

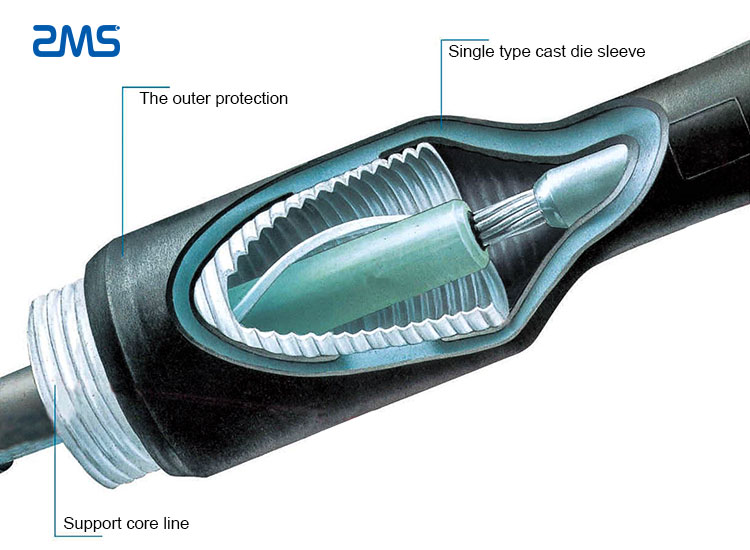

20kv Cold Shrink Cable Middle Terminal Joint

- This cable accessory adopts cold shrink technology in the form of a pre-tensioned casing to provide mechanical and moisture protection for the joint.

- It has an excellent record in terms of permanent sealing and maintaining elasticity, ensuring its long working life.

- The single-piece mold casing is more convenient for construction and has higher reliability.

- Support the core rope: Put the sleeve in the proper position. When the supporting core rope is pulled out, the insulating sleeve shrinks and closely adheres to the cable surface. Makes installation easier, no tools or heat is required.

- A wide range of applications: this product is suitable for 24kv voltage, 50 mm² to 500 mm² cable diameter. One size fits multiple wire diameters, saving inventory and money.

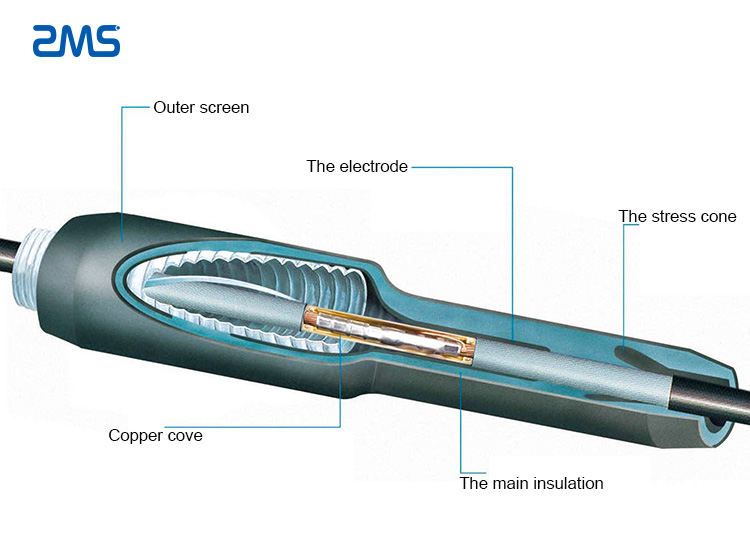

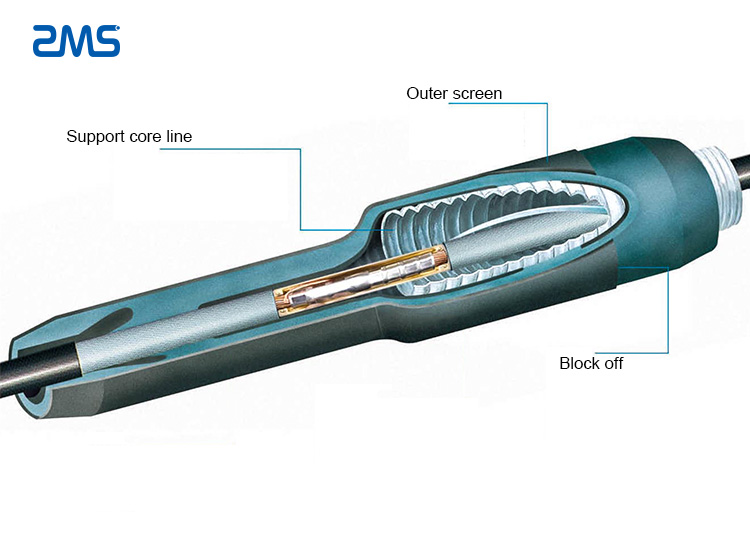

35kv Cold Shrink Cable Middle Joint---Through Joint

- Outer shield: The outer motor is molded with a certain thickness and small resistivity to achieve a reliable shielding effect.

- Inner electrode: sufficient length to completely cover the copper cover, no need to wrap any tape inside. A certain thickness and small resistivity are guaranteed, and at the same time, a reliable shielding effect is achieved.

- Stress cone: Our stress cone is optimized by finite element analysis software, corresponding to the stress cone curve. Obtain the best stress control curve, effectively reducing the electric field intensity.

- Copper cover: Apply the copper shield recovery method in the 110kv and above intermediate joints to the 35kv intermediate joint. The copper cover can tightly cover the metal nozzle and overlap with the electrode layer in the middle joint, thereby reducing partial discharge, uniform electric field distribution shape, and improving electrical performance and operating life.

- Main insulation: It is formed together with the inner electrode and the outer shield. No deamination between each other, no air gap, no partial discharge. The restoration of the three layers of the main body part can be completed with one shrink.

35kv Cold Shrink Cable Middle Joint---Insulated Joint

- Outer shield: Molded structure, using the main body of the connector to break the insulation between the outer shield, and realize cross-interconnection and other inter-layer grounding methods.

- Supporting core line: It is woven by the uniform laser welding point and the buckle method with confidential technology. Ensure that the insulating joint has greater strength under normal transportation and storage conditions, does not collapse, collapse, or deform. At the same time, it can be evenly released after installation and is easy to remove.

- Wide application range: It is suitable for many types of cables, and the expansion rate on the core rope is as high as 300%. When installed on the cable, sufficient cross-sectional pressure and excellent electrical performance can be obtained. One size is suitable for multiple cable diameters.

Note1: All cold shrink cable terminations and joints conform to the following international standards: IEC60502.4, VDE0278, IEEE48, IEEE404, JB/T 10740-2007, GB12706.4.

Note2: The outer diameter of the cable insulation is the final determining factor for the selection, and the conductor cross-section is for reference only.Inquire Us Now.

Technical Advantages of Cold Shrink Termination

ZMS cold-shrinkable cable terminals and joints adopt unique material formulas and manufacturing processes. It makes the termination head closely adsorb the main insulation of the cable and provides constant and long-lasting radial pressure on the cable body, with small partial discharges, high starting voltage, and higher insulation impact level than the current standard. It enables the high electric field strength at the termination surface to reach a safe range of 15V/mil, and the high potential shift is not concentrated near the cable shield cutoff but toward the cable end. As a result, the distribution of the insulation power plant outside the cable termination tends to be decentralized and uniform. As a result, the discharge voltage of the outer insulation is increased, so that the diameter of the whole cable terminal is reduced and the shape factor is increased, which has the effect of increasing the discharge voltage.

35kV fully cold-shrinkable cable terminals, using imported liquid silicone rubber as raw material, to ensure that the cable terminals have excellent insulating properties and high elasticity, always maintain constant radial pressure on the cable body after installation, and the cable body with the “breathing”.

About ZMS Cable Accessories Manufacturer

- ZMS Cable Group Co., Ltd. is a leading manufacturer and supplier of power cables and cable accessories and heat shrinkable products in global. ZMS company was established in 1990 and now has more than 30 years of development history.

- We always adhere to the competitive strategy of differentiation, internationalization and self-development. We aim to become a leader in the global cable and cable accessories industry. Our products have obtained ISO9001, ISO14001, UL, CSA and KEMA and other international certifications.

- ZMS company relies on excellent product quality, meticulous customer service, and efficient and fast delivery capabilities. We sincerely invite you to cooperate with you to achieve excellent results.

- ZMS factory has imported several large-scale equipment and production lines of power cables and cable accessories from Germany, Hong Kong and Taiwan.

- These production lines have laid a solid foundation for our R&D and quality assurance. Our cable accessories products have a high reputation in the Philippines, UAE, Kenya and other countries and regions.

- We not only produces high-quality cable terminations, but also types of cable insulators, cable lugs, cable clamps and other cable accessories made of top materials.