Industrial Instrumentation Cable

Industrial Instrumentation Cable are suitable for signal transmission, and control circuits for instruments or other electrical equipment. Instrument cables are generally usually installed indoors, suitable for humid environments. In the industrial industry, it is often used for communication, data, and voice transmission signals and services, and can also be used as the interconnection of electrical equipment and instruments.

Types: CU / PE / IS / OS / PVC / Lead / PVC / SWA / PVC.

Industrial Instrumentation Cable Types

It must be said that the models and specifications of instrumentation cables are very many and complex, ZMS through many years of sales cooperation experience lists the following kinds of hot-selling instrumentation cables for you to choose from, if you have other customized needs, welcome to email us.

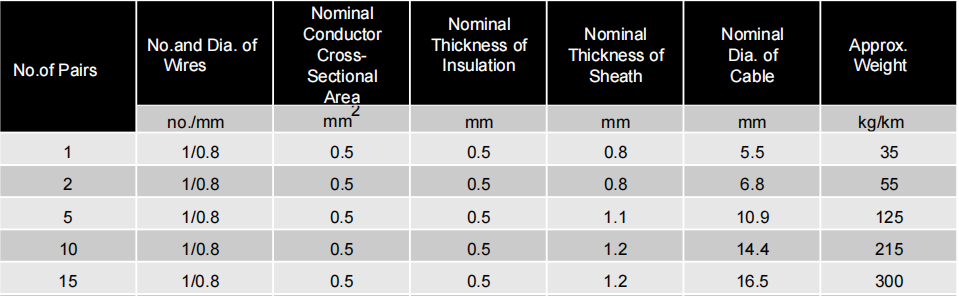

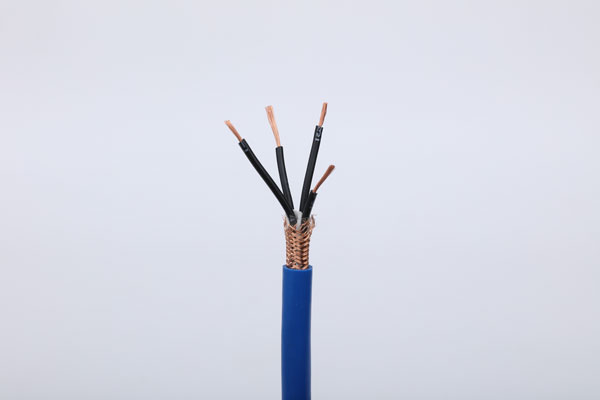

BS5308 Non Armored Instrument Cable

Conductor: Annealed or tinned copper

Dimensions: 0.5 mm² and 0.75 mm², Class 5 multi-strand, 0.5 mm² and 1.0 mm², Class 1 solid copper, 1.5 mm² and 2.5 mm², Class 2 multi-strand copper, in accordance with BS 6360

Insulation: PE (polyethylene)

Overall Shielding: Aluminum composite shielding, metal side inwards, next to 0.5mm² drain wire

Sheath: PVC (Polyvinyl Chloride)

Operating Temperature: -40˚C up to + 70˚C (fixed installation); 0˚C to +50˚C (during operation)

Minimum Bending radius: 5 x OD

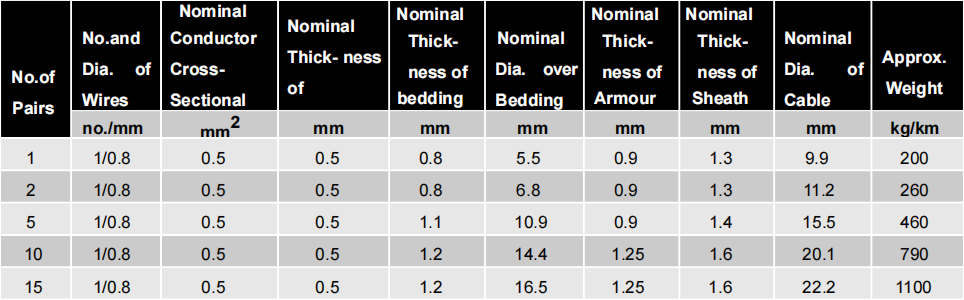

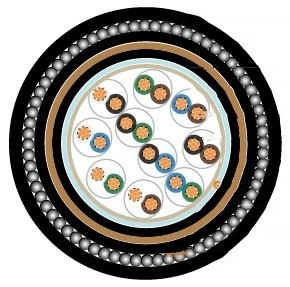

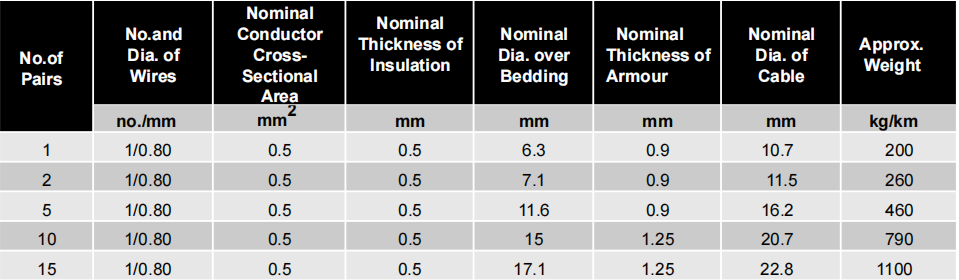

BS5308 Armored PE Insulation Instrument Cable

Conductor: Annealed copper or tinned copper.

Insulation: PE (polyethylene) to BS6234, Class 03.

Pairing: two cores twisted together with less than 100mm of insulation tape.

Bonding tape: transparent polymerized ester tape.

Overall shield: Aluminum-plastic composite shield, metal side inwards, next to 0.5 mm² drain wire

Inner jacket: PE (polyethylene) to BS6234, category 2C or 03 BS6234.

Armouring: Galvanized steel wire armouring

BS5308 PE Lead Sheath Instrument Cable

Conductor: Annealed or tinned copper, Dimensions: BS6360 compliant, 0.5mm² and 0.75mm², Type 5 multi-strand, 0.5mm² and 1.0mm², Type 1 solid copper, 1.5mm² and 2.5mm², Type 2 multi-strand copper

Insulation: PE (polyethylene), BS6234 compliant, Class 03.

Pairing: two cores twisted, with less than 100mm of insulation tape.

Bonding tape: transparent polymerized ester tape.

Overall shield: Aluminum-plastic composite shield, metal side inwards, next to the 0.5 mm² drain wire.

Inner jacket: PVC (Polyvinyl Chloride), according to BS6746, TM Category 1 or 6.

Advantages of ZMS Instrument Cables

Conductor Material

ZMS uses annealed copper conductors with tin/silver plated surfaces in the production of instrumentation cables, which prevents the core wire from being oxidized in long-term high-temperature environments and improves electrical conductivity.

Sheathing Insulation

Sheathing and insulation are made of polymers with excellent mechanical properties, able to withstand high-strength metal impacts and cuts. They have a very high tensile strength and can also withstand repeated bending over long periods.

Reinforcement Layer Polymer

A reinforcement layer is added to the cable, which is mainly a selected polymer material that prevents the shield from damaging the insulation and also enhances the overall mechanical properties of the cable.

In addition to the above basic characteristics, ZMS instrumentation cables also have the advantages of good resistance to electromagnetic interference (EMI), low capacitance, and high signal transmission accuracy.

Instrumentation Cable Selection

• According to the laying method, select the instrument cable protection serial number, whether it is armored or not, as well as the most basic size and specification.

• According to the conditions of use, area, and economy, choose copper core or aluminum core.

• According to the load size selection of specifications and several cores: lighting load selection of 4 cores, office buildings and important buildings selection of 4 +1 cores, less than 25mm2 when the selection of 5 cores.

• Voltage level should be matched with the line.

• 1kV and below the current of the cable is usually 2 times its power, and the purely resistive load current is 1.5 times its power.

• When the cable length is greater than 400 meters, the voltage drop should be considered when selecting cables.

• When selecting cables also take into account the starting current of the maximum load, the future development of the project, and the cross-section margin.

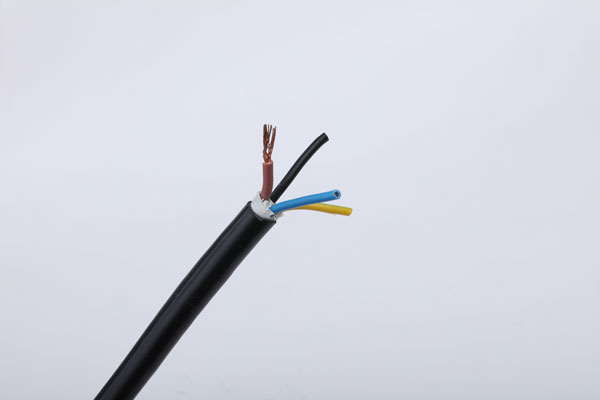

ZMS Industrial Instrumentation Cable Catalog

ZMS INSTRUMENT CABLE PDF

ZMS provides our partners around the world with brochures of our cable products, including aerial cables, submarine cables, control cables and other types of special cables, and more.

If you don’t know how to choose the product you need, or don’t find the cable type and size you need on this page, don’t worry. Contact us and send us your requirements, we can help you choose the right cable. You can provide us with the following information: cable voltage, conductor material, insulation and sheath material, shield type, armor type, etc. or you can provide us with cable installation environment, application requirements, etc. We will serve you wholeheartedly. ZMS cable supplier has a number of quality certifications: ISO 9000, ISO 9001, ISO14000, ISO14001, ISO18000, CE, IEC, BS, NFC, ASTM, DIN, etc.

Service of ZMS Company

Over Productions Service: ZMS has a wide range of cable and conductor products for you to choose from. We will provide caring services and professional project solutions for everyone who needs them.

Quality Certification Services: ZMS cable products are manufactured according to GB, IEC, BS, NFC, ASTM, DIN, and other international standards. Our technical team can customize cable products that meet your requirements according to your needs.

Profession Customer Service: ZMS provides free professional consulting services to provide you with one-stop project solution services and rapid product delivery solutions.

Delivery And Shipping Services: While we at ZMS provide high-quality cables, we also provide good delivery solutions. While ensuring the safe delivery of products, we provide the best packaging and transportation solutions, greatly reducing customers’ transportation costs.

Packaging of ZMS: ZMS cable packaging is provided in the form of wooden reels, corrugated boxes, and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.