HTLS Conductor

HTLS Conductor is the full name of a high-temperature, low-sag conductor. ZMS Cables manufactures a wide range of cables with HTLS Conductor materials. Including ACSS and ACSS/TW, G(Z)TACSR, Invar Conductor types, ACCR, ACCC/TW Conductors, etc.

HTLS Conductor Manufactured by ZMS are Characterized by

- Low conductor arc sag at high temperatures, high return temperatures, and low resistance.

- Replacement of conventional conductors without or with minor adjustments to steel tower structures or line corridors.

- Significantly increases the load capacity of transmission lines.

- Applications in transmission capacity increase where conductor strength loss (thermal limiting) and exceeding clearance limits (gap limiting) are considered, and conductor temperature is limited to a certain temperature.

ZMS HTLS Conductors Types

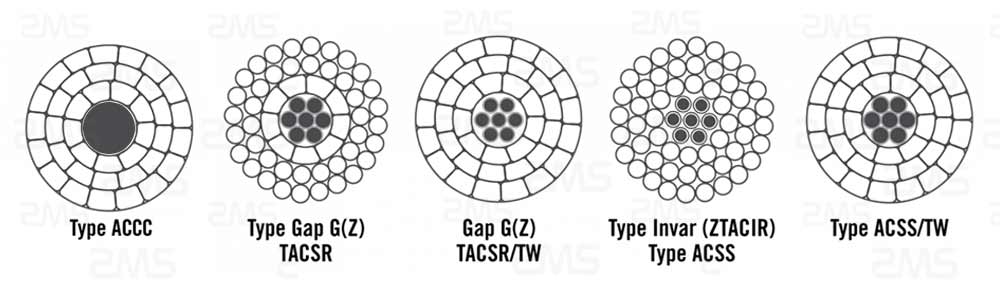

ACSS/TW—Aluminum Conductor Steel Supported/Trapezoidal Wire

- The product consists of a round or trapezoidal fully returned aluminum strand (1350-0) with high strength, ultra-high-strength (EHS), extra high strength (UHS) steel core.

- ACSS is capable of operating at high temperatures with the same arc droop as ACSR.

- The steel core wire has a hot-dipped galvanized, aluminum-clad, Zn-5% Al-MM Gafan anti-corrosion coating. With conventional hot-dipped galvanized steel cores, the wire runs at 180 °C.

- And with conventional hot-dipped galvanized steel core, the wire running temperature can reach 300℃.

ACCC/TW—Aluminum Conductor Composite Core

- ACCC/TW conductor is a new type of advanced conductor.

- It consists of a round or reminder fully annealed 1350-0 aluminum stranded wire (ACCC/TW) with an advanced carbon fiber/glass fiber polymer-based composite core single rod.

- The outer surface of the carbon fiber core rod is covered with a glass fiber insulator, so that there is no contact potential difference between the core rod and the aluminum strand, protecting the wire from electrochemical corrosion.

- ACCC/TW effectively increases the cross-sectional area of the green wire by 30% over the same diameter ACSR. As a result, its load capacity increases significantly.

- ACCC/TW wire has the advantages of light mass, large span, high tensile strength, small arc sag, low line loss, high conductivity, high load capacity, high operating temperature (up to 200 °C), and good corrosion resistance.

- It is the best HTLS conductor with the best application prospect at present.

ACCR—Aluminum Conductor Composite Reinforce

- ACCR consists of an AT3 aluminum-zirconium alloy with an Al2O3 ceramic limit-reinforced aluminum matrix composite core wire.

- The aluminum matrix composite core wire is similar in strength to steel and at the same time similar in mass to aluminum.

- This results in a lighter wire with better electrical conductivity.

- The aluminum matrix composite core has a high modulus of elasticity and a low thermal stretch (1/2 that of steel).

- ACCR conductors are mainly used to replace old conductors with severe ice cover and minimal high-temperature low sag clearance.

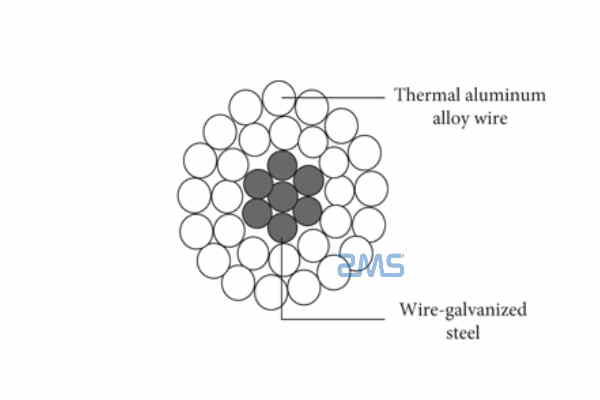

G(Z)TACSR—Gap-type Thermo-resistant Aluminum Alloy Conductor Steel Reinforced

- This product is made with a gap between the ultra-high strength galvanized steel core and the inner trapezoidal heat-resistant aluminum-zirconium alloy layer to allow the wire tension to be fully borne by the steel core.

- The G(Z)TACSR conductor is complex and labor-intensive to install.

- It requires disassembly of the aluminum wire at each termination and connection to expose the steel core.

- The addition of a small amount of Zr raises the recrystallization temperature of aluminum, significantly improving the load capacity and annealing characteristics.

- The wire can be run continuously at 210 °C without any reduction in tensile strength.

ZMS Advantages of HTLS Conductor

The HTLS cables produced by the ZMS manufacturer offer a wide range of advantages across a wide range of options. Today’s increased demand for electricity, the increasing difficulty of erecting the line corridors required for new overhead lines, and the rapid rise of renewable energy generation. There is an urgent need for transmission upgrades and transmission expansion.

High-temperature low sag conductors (HTLS conductors) are a new technology for upgrading transmission lines to increase the thermal rating to improve transmission capacity. HTLS conductors can operate at high temperatures (100 °C and above) for extended periods without significant deterioration in tensile strength or other mechanical, electrical, or chemical properties. The tensile length at the same temperature is significantly lower than that of conventional aluminum or steel core aluminum conductors.

Characteristics of HTLS Core Materials

- ACSS and ACSS/TW—(aluminum conductor steel supported/Trapezoidal wire, ACSS/TW), trapezoidal/steel core soft aluminum stranded wire. Annealed aluminum stranded wire + conventional steel core, operating temperature up to 250 °C.

- G(Z)TACSR—(Gap-type Thermo-resistant Aluminum Alloy Conductor Steel Reinforced). Gap-type steel core heat-resistant aluminum alloy strand, the operating temperature can reach 150℃.

- Invar Conductor—(Z)TACIR-ZTA1(Extra heat-resistant) Aluminum Conductor Invar Steel Reinforced. 210℃.

- ACCR—(Aluminum Conductor Composite Reinforce). Aluminum-based ceramic fiber core aluminum strand, continuous operation temperature 210℃, short time 240℃.

- ACCC/TW—(Aluminum Conductor Composite Core). Soft aluminum stranded wire with a carbon fiber core, continuous running temperature of 180℃.

| Core Conductor Material | Minimum Tensile Strength(MPa) | Modulus of Elasticity(GPa) | Min. Divine Length(%) | Coefficient of Linear Expansion | Allowable Operating Temperature(℃) | |

| Continuous | Short-time | |||||

| Galvanized Steel | 1379~1448 | 206 | 3.0-4.0 | 11.5 | 180 | 200 |

| Zn-5A1-MM Steel (B802) | 1379~1448 | 206 | 3.0-4.0 | 11.5 | 250 | 350 |

| High Strength Galvanized Steel (B606) | 1517~1620 | 206 | 3.0-3.5 | 11.5 | 180 | 200 |

| Zn-5A1-MM Steel (B803) | 1517~1620 | 206 | 3.0-3.5 | 11.5 | 250 | 350 |

| Ultra-high Strength Galvanized Steel | 1827~1965 | 206 | 3-3.5 | 11.5 | 180 | 200 |

| Zn-5A1-MM Ultra High Strength Steel | 1827~1965 | 206 | 3-3.5 | 11.5 | 250 | 300 |

| CTC ACCC/TW | 2137~2482 | 114 | 2.0 | 1.6 | 180 | 200 |

| 3M ACCR | 1379 | 220 | 0.64 | 6.0 | 250 | 300 |

| Aluminum Clad Steel(AW) 20.3% IACS | 1034~1344 | 162 | 3.0 | 13.0 | 150 | 200 |

| Aluminum Clad Invar Steel 14% IACS | 1207~1276 | 152 | 3.0 | 3.7 | 210 | 240 |

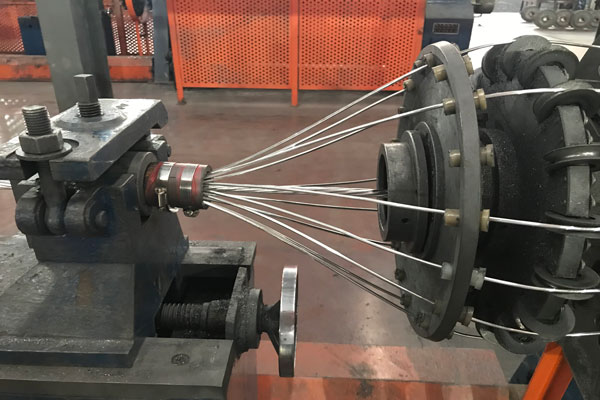

HTLS Conductor Factory

ZMS CABLE is very experienced in manufacturing and closing cases for HTLS conductors, and we have customers all over the world. ZMS has its cable factory and accurate and strict qualification certificate for cable products.

If you don’t know how to choose the cable products you need or can’t find the cable type and size you need on this page, don’t worry. Contact us and send us your requirements, and we can help you choose the right cable. You can provide us with the following information: cable voltage, conductor material, insulation and sheath material, shield type, armor type, etc. or you can provide us with cable installation environment, application requirements, etc. We will serve you wholeheartedly. ZMS Cable Supplier has some quality certifications: ISO 9000, ISO 9001, ISO14000, ISO14001, ISO18000, CE, IEC, BS, NFC, ASTM, DIN, etc.

ZMS Cable Service

Wide Cable Product Range

As a professional cable manufacturer and exporter, ZMS supplies a complete range of power cables, control cables, instrument cables, and conductors for global industrial projects.

International Standards & Custom Production

Products are manufactured according to IEC, BS, ASTM, DIN, GB, and other standards, with custom cable design available based on technical requirements.

Professional Technical Support

Free pre-sales consultation, product selection guidance, and one-to-one project solution support for different application environments.

Reliable Delivery Solutions

Optimized packaging and shipping plans to ensure safe delivery while helping reduce transportation risks and costs.

Export Packaging Protection

Wooden drums, cartons, or coils packaging with moisture-proof sealed cable ends and waterproof markings for international transport.