Insulated Cable

Insulated Cable & Wire has a variety of insulation materials, which are suitable for different needs and have different purposes. Its insulation materials are polyethylene(PE insulation), cross-linked polyethylene(XLPE insulation), polyvinyl chloride(PVC insulation), rubber insulation(ERP insulation), etc. Insulated wires made of different insulation materials are subject to strict quality system testing. Only cable products that meet the standards can be sold from the ZMS factory. The function of the cable insulation layer is to use a non-conductive substance to isolate or wrap the charged body to prevent electric shock and provide a safety measure for protection.

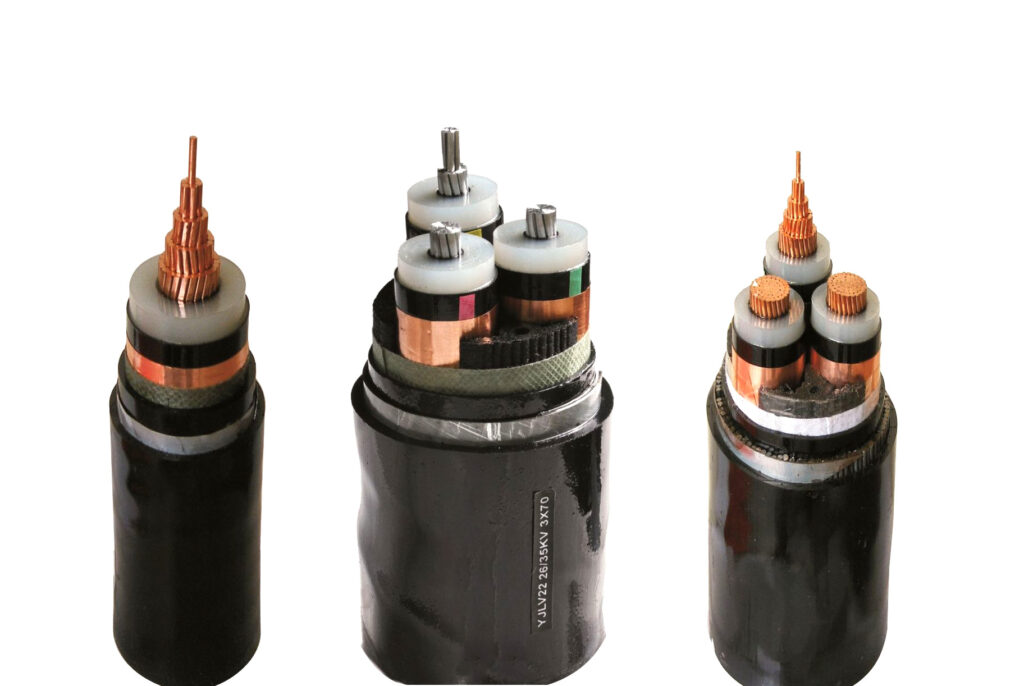

Types of XLPE/PVC Insulated Cable

PVC Insulated Cable

PVC insulated cable is a common product in the wire and cable industry. Its product features are good physical and mechanical properties, good processing performance, low cost and low price. However, it contains halogens, and the maximum amount of sheath is used.

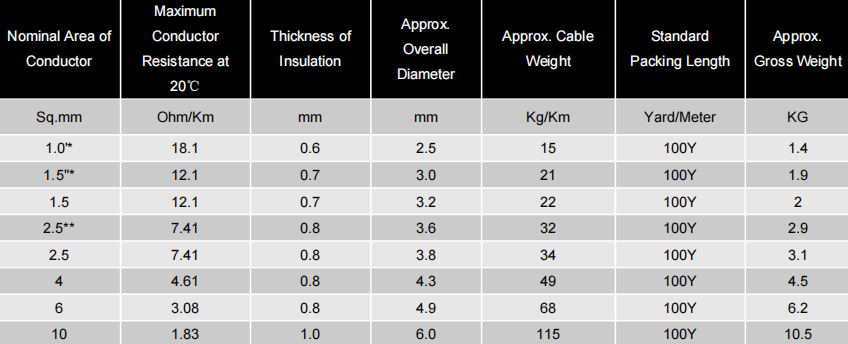

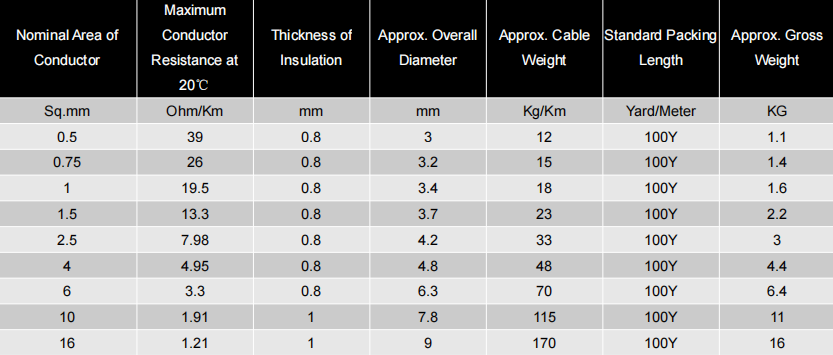

450/750v-Single Core Copper Conductor PVC Insulated Cables

Used for power devices, fixed wiring, and flexible connection appliances with rated voltage of 450/750V and below.

Conductor: Copper Conductor

Insulation: PVC

Core: Single / Medium core

Cable Inner Sheath: PVC

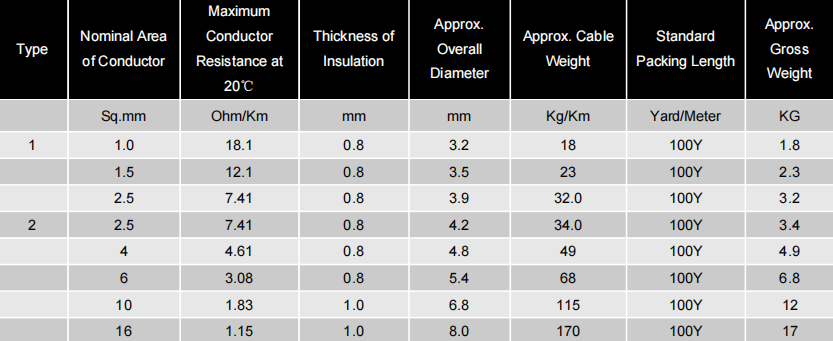

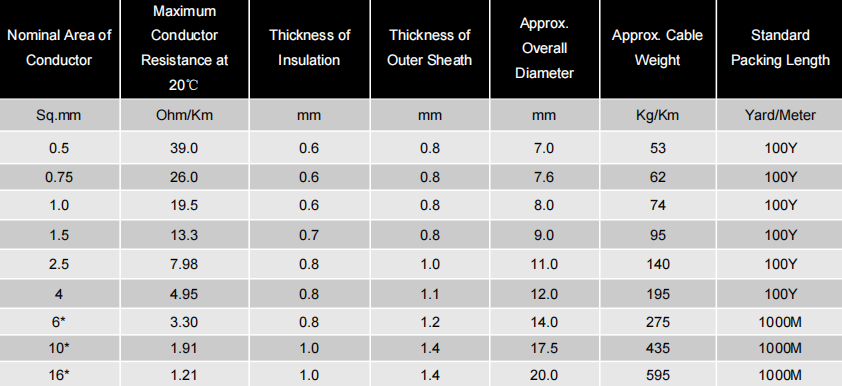

600/1000V-Single Core Copper Conductor PVC Insulated Cables

PVC insulated single-core cables are cables used to transmit and distribute electrical energy. For Switchgear And Controlgear Wiring Type Cu And Cr As Per BS 6231-1990.

Conductor: Copper Conductor

Insulation: PVC

Core: Single / Medium Core

Cable Outer Sheath: PVC

Twin and SIEMENS Cables

Twisted-Pair Wire consists of multiple sets of insulated copper wires twisted around each other, the internal medium of the twisted-pair wire is also copper, and the internal transmission is electrical signals, and according to the electromagnetic principle, the changing current produces a magnetic field.

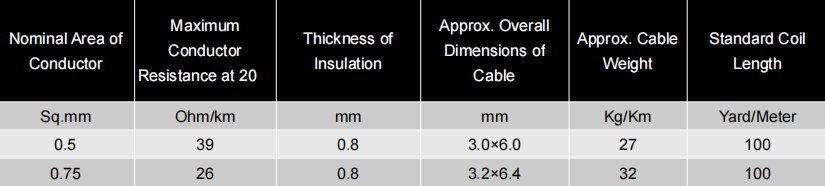

300/500V-Twin Flat Cable Copper Insulated Sheathed Cable

Conductor: Copper / Aluminum, based on client’s requirements

Construction: Bare copper wire

Insulation jacket: PVC sheath

Voltage: 450/1100V

Insulated 4mm 6mm 10mm Solar Cable Twin Core

* Excellent resistance to U.V., oil, greases, oxygen, water, fluids, salt, general weathering and ozone

* Excellent resistance to abrasion

* Halogen-free, flame retardant, low toxicity

* Excellent flexibility and stripping performance

* High current carrying capacity

Flexible Insulated Cable

Flexible Insulated Cable insulation layer and sheath are often made of natural rubber, styrene-butadiene rubber, ethylene-propylene rubber, etc. In addition to satisfying insulation properties and physical and mechanical properties, it also requires aging resistance and abrasion resistance. Some products require oil resistance and flame retardancy.

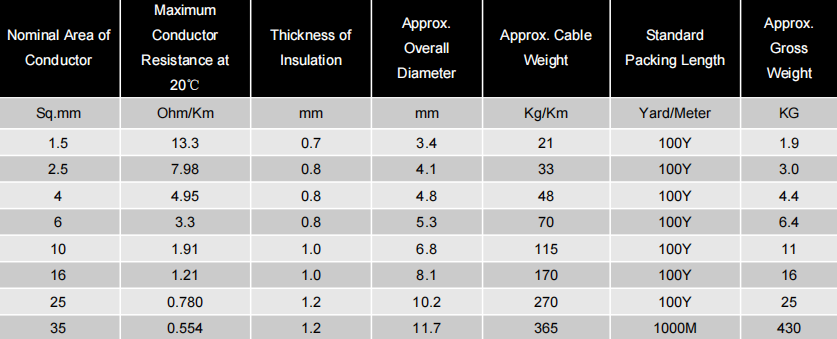

450/750V-Single Core Flexible Cables Copper Conductor

Super flexible rubber cables can be fixedly laid in various environments, such as indoor/outdoor, overhead, cable duct, or tunnel.

Model: H07RN-F YC / YCW

Voltage: 300 / 500V, 450 / 750V

Conductor: Copper

Insulation: Rubber

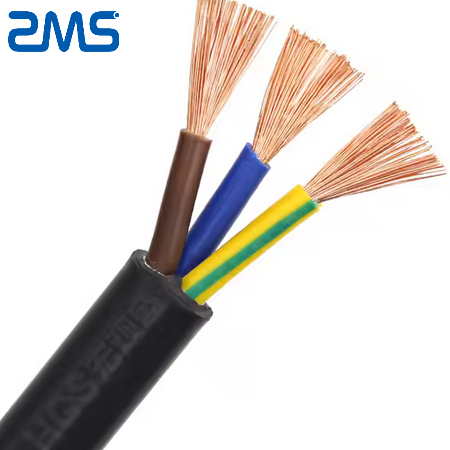

300/500V-Two Three Cores Flexible PVC Insulated Coppe Cable

100% complete length, no less but more.

99.99% oxygen-free copper, low resistance high conductivity.

100% environmental material, fire retardant

Insulated Cable Lugs

In addition to the production of various standardized insulated cable types, ZMS also produces cable accessories such as insulated cable lugs. For example, DTL-4 pre-insulated bimetallic lugs are used to establish connections between LV-ABC cables and electrical equipment.

Insulated cable clamp, insulated cable connector, insulated cable staples, etc. ZMS Cables can customize the right cable accessory according to the customer’s request for quotation.

XLPE PVC Insulated Cable Catalog

ZMS XLPE PVC INSULATED CABLE PDF

ZMS provides our partners around the world with brochures of our cable products, including aerial cables, submarine cables, control cables and other types of special cables, and more.

If you don’t know how to choose the product you need, or don’t find the cable type and size you need on this page, don’t worry. Contact us and send us your requirements, we can help you choose the right cable. You can provide us with the following information: cable voltage, conductor material, insulation and sheath material, shield type, armor type, etc. or you can provide us with cable installation environment, application requirements, etc. We will serve you wholeheartedly. ZMS cable supplier has a number of quality certifications: ISO 9000, ISO 9001, ISO14000, ISO14001, ISO18000, CE, IEC, BS, NFC, ASTM, DIN, etc.

Difference between XLPE Insulated and Others

When choosing a cable, how do you choose whether you need a cable that is insulated or non-insulated, in addition to thinking about the application environment, you also need to understand the difference between the two types of cables in terms of performance and technical parameters.

- Cross-linked polyethylene insulated cable and ordinary insulated cable material differences.

- Temperature resistance: the temperature resistance level of ordinary insulated cables, generally 70 ° C, cross-linked polyethylene insulated cable temperature resistance up to 90 ° C.

- Different flow-carrying capacity: for the same conductor cross-sectional area of the cable, cross-linked polyethylene insulated cable should be greater than the flow-carrying capacity of ordinary insulated cable.

- The scope of application: ordinary insulated cables in the combustion, will release toxic HCl smoke, fire requirements for low toxicity can not use ordinary insulated cables. Cross-linked polyethylene insulated cables are suitable for power distribution networks, industrial installations, or other areas requiring high-capacity electricity, Used for fixed laying in AC 50Hz, rated voltage 6kV ~ 35kV power transmission and distribution lines, the main function is to transmit power.

Summary: Difference Between PVC PE XLPE

- PVC: Low working temperature, short heat aging life, small transmission capacity, low overload capacity, smoke and acid gas hazard in case of fire. Wire and cable industry general products, good physical and mechanical properties, good processing performance, low cost and selling price. However, it contains halogen, and the amount of sheath is ZUI big.

- PE: Excellent electrical properties, all the advantages of PVC. Commonly used in wire or cable insulation, data line insulation material, low dielectric constant, suitable for data lines, communication lines, a variety of computer peripheral line core insulation.

- XLPE: Almost as good as the electrical properties of PE, at the same time, the long-term working temperature is relatively higher than PE, mechanical properties better than PE, aging resistance is better. New high temperature resistance, environmental performance is good environmental protection products, thermosetting plastic. Commonly used in electronic wire and high environmental requirements.

ZMS Cable Service

Wide Cable Product Range

As a professional cable manufacturer and exporter, ZMS supplies a complete range of power cables, control cables, instrument cables, and conductors for global industrial projects.

International Standards & Custom Production

Products are manufactured according to IEC, BS, ASTM, DIN, GB, and other standards, with custom cable design available based on technical requirements.

Professional Technical Support

Free pre-sales consultation, product selection guidance, and one-to-one project solution support for different application environments.

Reliable Delivery Solutions

Optimized packaging and shipping plans to ensure safe delivery while helping reduce transportation risks and costs.

Export Packaging Protection

Wooden drums, cartons, or coils packaging with moisture-proof sealed cable ends and waterproof markings for international transport.