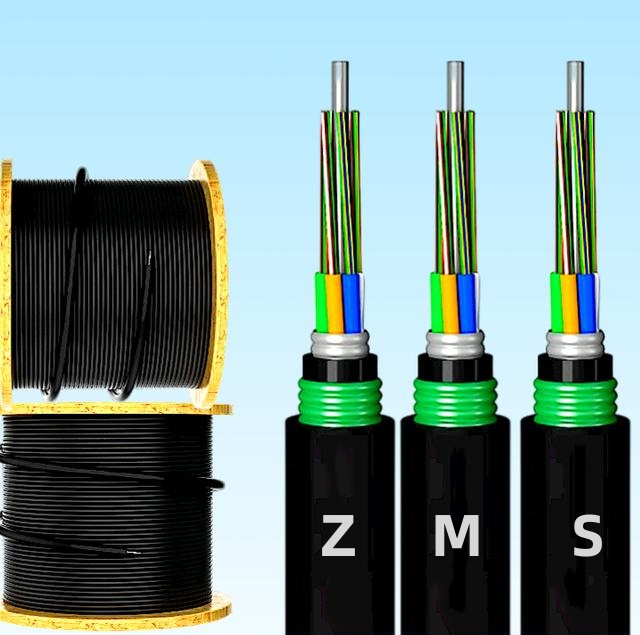

Armoured Fiber Optic Cable

Armored fiber optic cables are fiber optic cables that have a protective “armor” (stainless steel armored tubing) wrapped around the fiber optic cable core. This stainless steel armored tubing protects the core from animal tears, moisture erosion, or other damage. Today, armored fiber optic cables are the solution for campus networks, data centers, and industrial applications.

One of the GYTS fiber optic cables or fibers is a flexible and transparent fiber. It is stretched from glass (silica) or plastic and is slightly thicker than the diameter of a human hair. Fiber optics are most commonly used to transmit signals between the two ends of an optical fiber.

ZMS supports customization, please feel free to contact us.

Armored Fiber Optic Cable Structure and Types

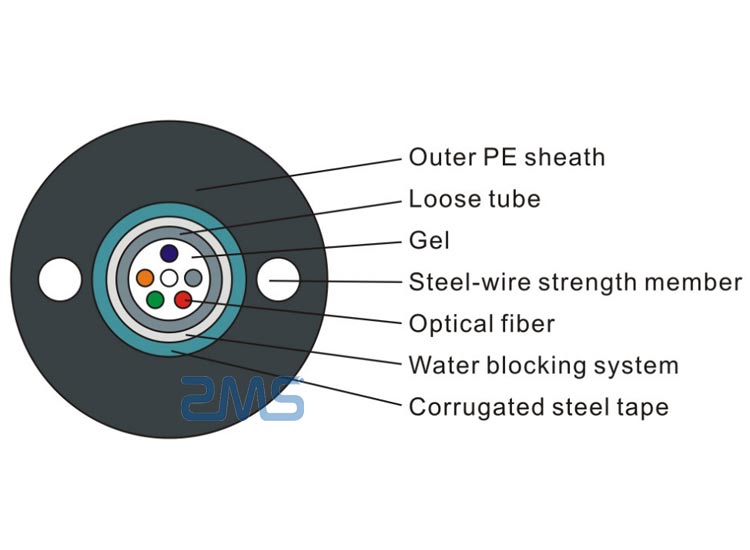

GYXTW Single Core Fiber Optic Cable

GYXTW single mode armored fiber optic cable is made of 250μm optical fiber in a high-modulus material pine sleeve filled with waterproof compound. The loose tubing is wrapped longitudinally with double-sided plastic coated steel tape (PSP). The water barrier material is added between the steel tape and the loose tubing to ensure compactness and longitudinal water resistance of the fiber optic cable. Two parallel steel wires are placed on both sides and then extruded into a polyethylene sheath to form the cable.

– Optical fiber loose casing.

– Water-blocking material longitudinally wrapped around the center PBT loose tube.

– Round composite rolled steel tape bonded polyethylene outer sheath.

– Strengthen parallel 4 steel wire is located outside the round composite steel tape armor layer.

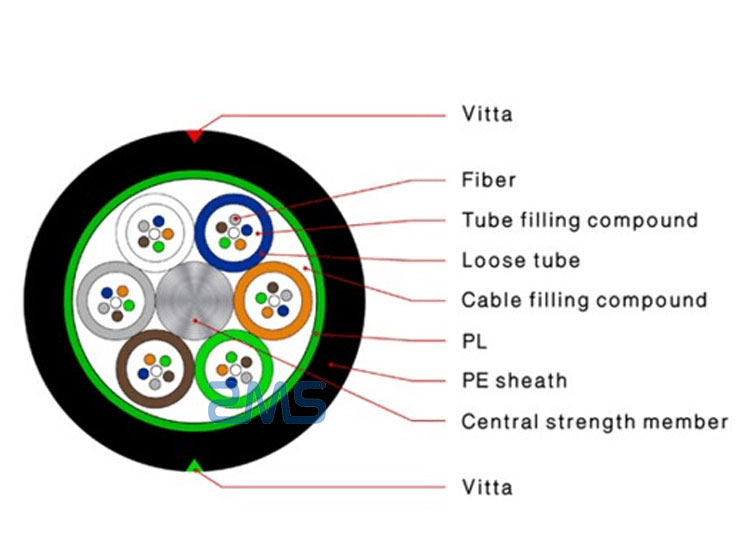

GYTS Fiber Optic Cable

The structure of the GYTS fiber optic cable is 250 µm optical fiber in a high modulus material made of a loose tube, the loose tube is filled with a waterproof compound. At the center of the core is a metal reinforcement core, which is extruded with a layer of polyethylene (PE) for some cores. The loose sleeving and filler rope are twisted around the central reinforcement to form a compact and rounded core, with gaps in the core filled with a water-blocking filler. Double-sided plastic-coated steel tape (PSP) is wrapped longitudinally and then extruded with a PE sheath to form the cable.

– PBT optical fiber loose sleeve.

– High-strength center-reinforced phosphorized steel wire.

– Cable core filled with oil paste.

– Loose-sleeved laminated structure.

– Steel – polyethylene bonded sheath.

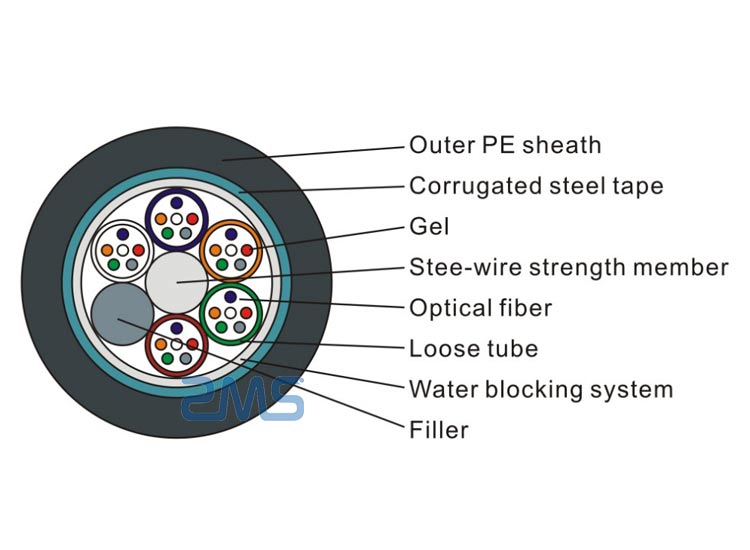

GYFTY Fiber Optic Cable

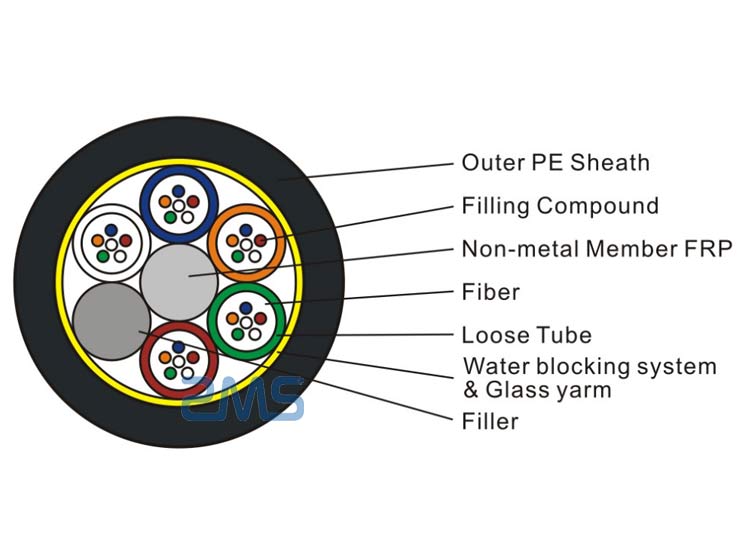

The structure of GYFTY fiber optic cable is 250 µm optical fiber in a high modulus material made of loose sleeving, the loose sleeving filled with a waterproof compound. The center of the core is an FRP non-metallic reinforcement core, around which the loose tubing (and filler rope) is twisted to create a compact and round core with a water barrier filler in the gaps. The gaps inside the core are filled with water barrier filler. The cable core is extruded with a layer of polyethylene sheath to create the cable.

– Non-metallic reinforcement and laminated structure design to ensure that the optical cable has excellent mechanical and temperature characteristics.

– The tube is filled with special oil paste, providing critical optical fiber protection.

– The cable core is filled with water-blocking ointment for effective waterproofing.

– High-strength non-metallic reinforcement to bear the axial load.

– The outer sheath has good anti-UV radiation performance.

GJAFKV Indoor Bundled Armored Fiber Optic Cable

Fiber optic cable structure is a multi-core bundled mini ф250μm fiber surface applied to strengthen the role of multi-stranded aramid, in the stranded surface extrusion of a layer of PVC or LSZH inner jacket as a sub-unit, multi-core bundled sub-unit stranded into a circle in the outer layer of a layer of steel wire armor, steel wire armor applied to a small amount of aramid, and then extruded PVC or LSZH outer sheath. Refer to YD/T 2488-2013, IECA-596, GR-409, IEC794, and other standards; comply with UL certification OFNR, and OFNP requirements.

– Mini-Bundle fiber optic cable, high strength aramid reinforced, high-performance jacket material outer protection.

– Small bending radius, lightweight, soft, flexible, and easy to splice.

– Flat steel wire armored, improve the pressure resistance and rodent-proof ability of fiber optic cable.

– Good mechanical and environmental performance.

– Flame retardant or non-flame retardant outer sheath, providing good safety protection.

Optical Properties

| / | G.652 | G.655 | 50/125μm | 62.5/125μm | |

| Attenuate (+20℃) | @850nm | / | / | ≤3.0dB/km | ≤3.0dB/km |

| @1300nm | / | / | ≤1.0dB/km | ≤1.0dB/km | |

| @1310nm | ≤0.36dB/km | ≤0.36dB/km | / | / | |

| @1550nm | ≤0.22dB/km | ≤0.23dB/km | / | / | |

| Bandwidths (Class A) | @850 | / | / | ≥500MHZ·km | ≥500MHZ·km |

| @1300 | / | / | ≥1000MHZ·km | ≥600MHZ·km | |

| Numerical Aperture | / | / | / | 0.200±0.015NA | 0.275±0.015NA |

| Fiber Cutoff Wavelength | / | ≤1260nm | ≤1480nm | / | / |

Structural Parameters

| Cable Type | Tight Diameter mm | Cable Diameter mm | Cable Weight Kg/km | Tensile Strength Long/Short Term N | Crush Resistance Long/Short Term N/100m | Bending Radius Static/Dynamic mm |

| GJSFJBV | 0.6 | 2.0*4.1 | 30 | 300/750 | 200/1000 | 20H/10H |

| GJSFJBV | 0.6 | 2.8*5.7 | 35 | 300/750 | 200/1000 | 20H/10H |

| GJSFJBV | 0.9 | 3.0*6.1 | 43 | 300/750 | 200/1000 | 20H/10H |

ZMS Cable Factory

ZMS CABLE is very experienced in manufacturing and closing cases for outdoor armored fiber optic cables, and we have customers all over the world. ZMS has its cable factory and accurate and strict qualification certificate for cable products.

If you don’t know how to choose the cable products you need or can’t find the cable type and size you need on this page, don’t worry. Contact us and send us your requirements, and we can help you choose the right cable. You can provide us with the following information: cable voltage, conductor material, insulation and sheath material, shield type, armor type, etc. or you can provide us with cable installation environment, application requirements, etc. We will serve you wholeheartedly. ZMS Cable Supplier has some quality certifications: ISO 9000, ISO 9001, ISO14000, ISO14001, ISO18000, CE, IEC, BS, NFC, ASTM, DIN, etc.

Service of ZMS Company

Over Productions Service: ZMS has a wide range of cable and conductor products for you to choose from. We will provide caring services and professional project solutions for everyone who needs them.

Quality Certification Services: ZMS cable products are manufactured according to GB, IEC, BS, NFC, ASTM, DIN, and other international standards. Our technical team can customize cable products that meet your requirements according to your needs.

Profession Customer Service: ZMS provides free professional consulting services to provide you with one-stop project solution services and rapid product delivery solutions.

Delivery And Shipping Services: While we at ZMS provide high-quality cables, we also provide good delivery solutions. While ensuring the safe delivery of products, we provide the best packaging and transportation solutions, greatly reducing customers’ transportation costs.

Packaging of ZMS: ZMS cable packaging is provided in the form of wooden reels, corrugated boxes, and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.

_副本.png)