AAC Conductor

All Aluminum Conductor (AAC) is an overhead transmission conductor consisting entirely of stranded concentric aluminum wires. AAC conductors are known for their excellent conductivity, corrosion resistance, and light weight, and are widely used in urban distribution networks and coastal transmission lines. Get a free quote quickly.

AAC Conductor Structure

The structure of the AAC all-aluminum conductor is simple, but very critical. It is a conductor composed of multiple strands of hard-drawn round aluminum wire (1350-H19) twisted concentrically. It does not contain a steel core. All strands are made of aluminum. It has a compact structure and excellent conductivity.

Conductor Material: high-purity aluminum wire (usually 1350-H19 hard aluminum), with good conductivity and corrosion resistance.

ZMS Stranding Process: Multiple strands of aluminum wire are stranded in concentric layers.

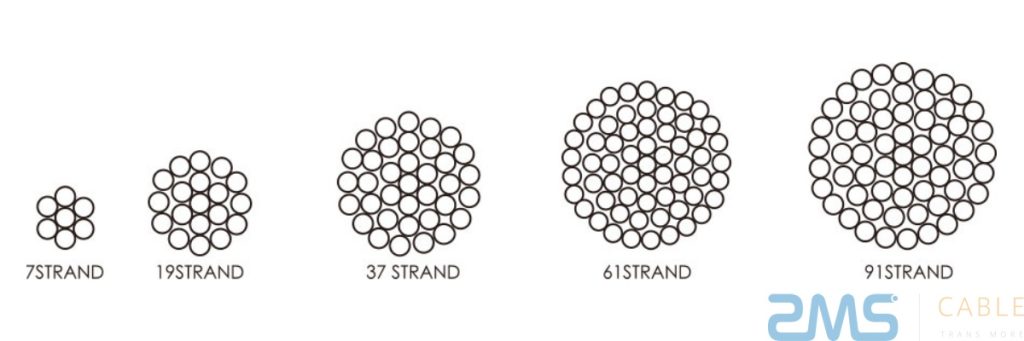

- Common structures include 7 strands, 19 strands, 37 strands, 61 strands, and so on. The more strands, the thicker the conductor and the better the flexibility.

- Each layer is typically twisted in opposite directions, such as the inner layer being right-twisted and the outer layer being left-twisted, to enhance structural stability.

No Steel Core: Unlike the ACSR conductor structure, AAC is an all-aluminum structure, so it is lighter in weight, but has lower tensile strength, and is suitable for short-distance power transmission or urban overhead lines.

Common Strand Counts For AAC Conductors

The aluminium stranded conductors produced by ZMS are twisted with different strands according to the customer’s specific cross-sectional areas and usage scenarios. The number of strands not only determines the diameter and flexibility of the conductor but also affects its mechanical strength and conductive properties.

AAC Conductor Size chart

Strand of Counts | Structural Form | Typical Uses & Effects |

| 7 Strands | 1 center wire + 6 outer wires | Used for small cross-section conductors, lightweight, suitable for low current, short distance transmission or distribution lines. |

| 19 Strands | 1 center line + 6 second layers + 12 third layers | It is commonly used for medium cross-sections, has a good balance between strength and conductivity, and is suitable for general overhead lines. |

| 37 Strands | 1+6+12+18 | Improves conductor flexibility and current carrying capacity, suitable for longer transmission lines or high current applications. |

| 61 Strands | 1+6+12+18+24 | Used for large-section AAC conductors, with large current capacity and strong mechanical strength, mostly used in urban trunk lines or special engineering projects. |

AAC Product Features

Excellent Conductivity: AAC cables are made of high-purity aluminum, generally EC Grade aluminum, with an aluminum purity of more than 99.5%, so they have a low resistivity, making them have good conductivity and suitable for short-distance, high-current power transmission scenarios.

Lightweight & High Strength: Compared with steel-core aluminum stranded wire (such as ACSR), AAC does not contain a steel core and has a lighter weight. It is suitable for overhead lines that do not require high mechanical strength, especially urban distribution networks and wiring projects in small spaces.

Good Corrosion Resistance: The all-aluminum structure has strong resistance to moisture, salt spray, and chemical corrosion, and is especially suitable for use in coastal areas, areas with severe industrial pollution, or hot and humid areas.

Easy Installation & Low Cost: Due to its lightweight and good flexibility, AAC conductors are easier to operate during installation, reducing construction time and labor costs; later maintenance is simple and has a long service life.

Environmentally Friendly & Recyclable: Aluminum is a recyclable material that is in line with the direction of green energy and sustainable development

AAC Conductor Technical Specifications

(According to IEC 61089 / ASTM B231 / BS 215)

Conductor Name | Stranding (No./Dia mm) | Nominal Area (mm²) | Overall Diameter (mm) | DC Resistance at 20°C (Ω/km) | Rated Tensile Strength (kN) | Approx. Weight (kg/km) |

AAC 16 | 7 / 1.70 | 15.9 | 5.1 | 1.91 | 4.2 | 43 |

AAC 25 | 7 / 2.14 | 25.1 | 6.4 | 1.20 | 6.2 | 68 |

AAC 35 | 7 / 2.52 | 34.9 | 7.6 | 0.87 | 8.7 | 94 |

AAC 50 | 7 / 3.10 | 53.0 | 9.3 | 0.641 | 13.0 | 142 |

AAC 70 | 7 / 3.70 | 75.2 | 11.1 | 0.446 | 18.3 | 200 |

AAC 95 | 7 / 4.26 | 99.9 | 12.8 | 0.335 | 24.1 | 267 |

AAC 100 | 19 / 2.14 | 68.0 | 10.7 | 0.493 | 17.1 | 181 |

AAC 120 | 19 / 2.34 | 82.1 | 11.7 | 0.409 | 20.6 | 218 |

AAC 150 | 19 / 2.52 | 94.7 | 12.6 | 0.353 | 23.8 | 252 |

AAC 185 | 19 / 2.85 | 121.0 | 14.3 | 0.276 | 30.3 | 321 |

AAC 210 | 19 / 3.00 | 134.0 | 15.0 | 0.253 | 33.5 | 355 |

AAC 240 | 37 / 2.52 | 185.0 | 17.6 | 0.189 | 46.0 | 495 |

AAC 300 | 37 / 2.85 | 236.0 | 19.9 | 0.148 | 58.8 | 626 |

AAC 400 | 61 / 2.85 | 387.0 | 24.9 | 0.091 | 96.0 | 1024 |

AAC Conductor Applications

Bare all-aluminum conductors (AAC) are primarily used in:

- Overhead distribution lines

- Short-distance transmission lines

- Coastal power networks

- Densely populated urban areas

ZMS Standards & Certificates

- IEC 61089

- ASTM B231

- BS 215 Part 1

- SGS / ISO9001 / Type Test reports available on request

ZMS Packing & Delivery

ZMS Cable packaging is provided in the form of wooden reels, corrugated boxes, and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.

Common FAQ

What is the difference between AAC and ACSR conductor?

Can AAC be used in high-voltage transmission lines?

How to choose the right size of AAC conductor?

Ready to order AAC conductors or need a customized quote?