Solar Panel

The solar panel system is a power generation system of photovoltaic modules. It includes mainly includes solar panels, batteries, controllers, and inverters. Other auxiliary equipment includes PV brackets, Solar cables, etc. In addition, depending on the system’s capacity, it may be necessary to configure convergence boxes, AC and DC distribution cabinets, and other equipment.

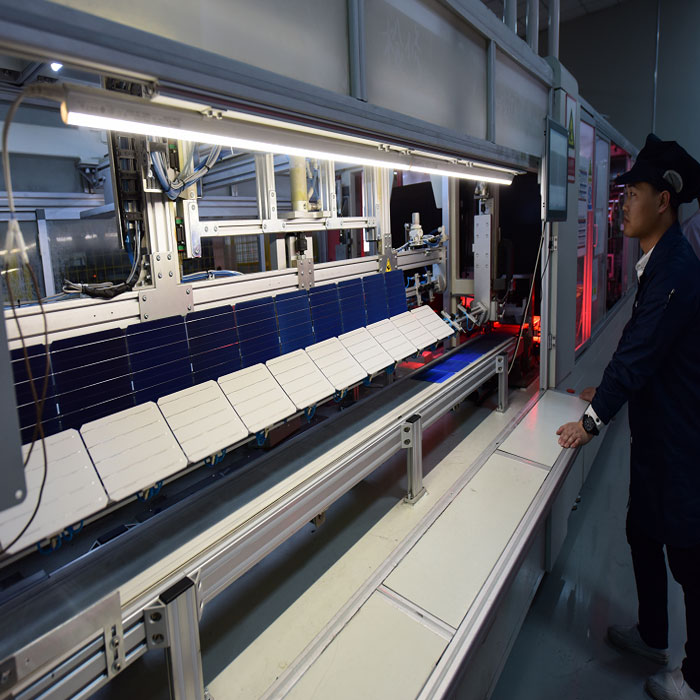

Solar panels (also called solar modules) are the core part of a solar power system and the most essential part of a solar power system.

Solar cells, also known as “solar chips” or “photovoltaic cells, ” are thin sheets of optoelectronics semiconductors that directly generate electricity. A single solar cell cannot be used directly as a power source. ZMS solar photovoltaic system products can be widely used in homes, ranches, base station projects, and other electricity consumption.

Classification of Solar Panels

Monocrystalline Solar Panels

Monocrystalline solar panels are modules made of high conversion efficiency monocrystalline silicon cells in different series and parallel arrays.

ZMS monocrystalline solar panels are rugged and have a life expectancy of up to 20 years. These solar panels offer higher conversion efficiency than polycrystalline solar panels and are more cost-effective to produce.

- Glass: ultra-white fabric tempered glass, thickness 3.2mm, in the wavelength range of the solar cell spectral response (320-1100nm) light transmission rate of 91% or more. It is resistant to ultraviolet radiation and the light transmission rate does not decrease. Tempered glass components can withstand the impact of a 25mm diameter puck at a speed of 23m/s.

- EVA: High-quality EVA film layer with a thickness of 0. 5mm is used as the sealing agent of the solar cell and the connecting agent between glass and TPT. It has high light transmittance and anti-aging ability.

Performance standards of EVA film for solar cell encapsulation after curing

Light transmittance greater than 90%; cross-linking degree greater than 65-85%; peel strength (N/cm), glass / adhesive film greater than 30. TPT / adhesive film greater than 15. temperature resistance: high temperature 85 ℃, low temperature -40 ℃. - TPT: the back side of the solar cell, aging resistance, corrosion resistance, UV radiation resistance, impermeability, and other basic requirements.

- Frame: The aluminum alloy frame used has high strength and strong resistance to mechanical impact.

model number | rating | Component efficiency | Maximum power point voltage | Maximum power point current | Product Size |

DEG20C.20 580W | 580 | 20.5 | 34.4 | 17.3 | 2384*1096*35mm |

DEG20C.20 585W | 585 | 20.7 | 34.4 | 17.3 | 2384*1096*35mm |

DEG20C.20 590W | 590 | 20.8 | 34.4 | 17.3 | 2384*1096*35mm |

DEG20C.20 595W | 595 | 21 | 34.4 | 17.3 | 2384*1096*35mm |

DEG20C.20 600W | 600 | 21.2 | 34.4 | 17.3 | 2384*1096*35mm |

Polycrystalline Silicon Solar Panels

Polycrystalline solar panels are made of polycrystalline solar cells arranged in different arrays to form photovoltaic modules of different powers to meet the electricity needs of different appliances.

When it comes to production costs, polycrystalline solar panels are somewhat cheaper than monocrystalline solar panels. They have a lower total production cost and save on electricity consumption. zms polycrystalline solar panels are cheaper than monocrystalline panels. These 500W solar panels are also the most widely used PV modules.

- Tempered glass Its role is to protect the main body of power generation (such as cells), the selection of light transmission is required. 1.1. light transmission must be high (generally 91% or more). 1.2. ultra-white tempering treatment.

- EVA is used to bond and fix the tempered glass and power generation body (such as cells), the merits of transparent EVA material directly affect the life of the module. EVA exposed to air is prone to aging and yellowing, which affects the light transmission of the module, thus affecting the quality of the module’s power generation. In addition to the quality of EVA itself, the impact of the lamination process on the component manufacturers is also very large. Such as EVA adhesive degree is not up to standard, EVA and tempered glass, and backplane bonding strength is not enough, which will cause early aging of EVA, affecting the life of the module.

- The main role of the cell is to generate electricity, the main body of the power generation market is the mainstream of crystalline silicon solar cells, and thin-film solar cells. Both have advantages and disadvantages for crystalline silicon solar cells, equipment costs are relatively low, but the consumption and cell costs are very high, and high photoelectric conversion efficiency. In outdoor sunlight power generation is more suitable for thin film solar cells, with relatively high equipment costs, but consumption and battery costs are very low, but the photoelectric conversion efficiency is relatively more crystalline silicon cells by more than half, but the low light effect is very good, in ordinary light can also generate electricity, such as the calculator on the solar cells.

- EVA’s role as above, the main bonding package power generation body and backplane.

- Backsheet role, sealing, insulation, waterproof (generally used TPT, TPE, and other materials must be resistant to aging, most component manufacturers have a warranty of 25 years, tempered glass, and aluminum alloy are generally no problem, the key is in the backplane and silicone whether it can meet the requirements.

- Aluminum alloy protects the laminate and plays a certain sealing, and support role.

- Junction box protects the entire power generation system, and plays the role of the current transfer station, if the component short circuit junction box automatically disconnects the short-circuiting battery string to prevent burning the entire system junction box in the most critical is the choice of the diode, according to the type of cell in the component different, corresponding to the diode is not the same.

- Silicone sealing role used to seal the components and aluminum alloy frame, components, and junction box junction some companies use double-sided tape, and foam to replace silicone, China’s domestic common use of silicone, the process are simple, convenient, and easy to operate, and the cost is very low.

Solar Panel Parameters

Maximum Power-PMAX(Wp) | 580 | 585 | 590 | 595 | 600 |

Power Tolerance-PMAX(W) | 0~+5 | ||||

Operating Voltage at Maximum Power Point-VMPP(V) | 33.8 | 34.0 | 34.2 | 34.4 | 34.6 |

Maximum Power Point Operating Current-IMPP(A) | 17.16 | 17.21 | 17.25 | 17.30 | 17.34 |

Open Circuit Voltage-Voc(V) | 40.9 | 41.1 | 41.3 | 41.5 | 41.7 |

Short-Circuit Current-Isc (A) | 18.21 | 18.26 | 18.31 | 18.36 | 18.42 |

Component Efficiencynm (%) | 20.5 | 20.7 | 20.8 | 21.0 | 21.2 |

Measured values under standard test conditions (atmospheric mass AM1.5, irradiance 1000W/m², cell temperature 25°C) Measuring tolerance: +3%

Maximum Power-PMAX(Wp) | 621 | 626 | 631 | 637 | 642 |

Operating Voltage at Maximum Power Point-VMPP(V) | 33.8 | 34.0 | 34.2 | 34.4 | 34.6 |

Maximum Power Point Operating Current-IMPP(A) | 18.36 | 18.41 | 18.46 | 18.51 | 18.55 |

Open Circuit Voltage-Voc(V) | 40.9 | 41.1 | 41.3 | 41.5 | 41.7 |

Short-Circuit Current-Isc (A) | 19.48 | 19.54 | 19.59 | 19.65 | 19.71 |

Irradiance Ratio(rear/front) | 10% | ||||

Maximum Power-PMAX(Wp) | 439 | 443 | 447 | 451 | 454 |

Operating Voltage at Maximum Power Point-VMPP(V) | 31.5 | 31.7 | 31.9 | 32.0 | 32.2 |

Maximum Power Point Operating Current-IMPP(A) | 13.93 | 13.97 | 14.01 | 14.06 | 14.10 |

Open Circuit Voltage-Voc(V) | 38.5 | 38.7 | 38.9 | 39.1 | 39.3 |

Short-Circuit Current-Isc (A) | 14.68 | 14.72 | 14.76 | 14.80 | 14.84 |

NOCT: Irradiance 800W/m², ambient temperature 20°C, wind speed 1m/s

Cell Type | Monocrystal |

Number of Cells | 120 Pieces |

Component Size | 2172x1303x35mm |

Weight | 35.3kg |

Glass | 2.0 mm, high permeable, AR coated hot reinforced glass |

Packaging Materials | POE/EVA |

Backboard | 2.0 mm, hot-reinforced glass (white mesh glass) |

Frame | A 35 mm aluminum frame |

Connecting Box | Protection level: IP 68 |

Cable | 4.0mm², special photovoltaic special cable Vertical installation: negative electrode 280mm / positive electrode 280mm The length can be customized |

Connector | TS4 /MC4-EV02 |

Temperature Rating | Absolute Rating | ||

NOCT (Rated Battery Operating Temperature) | 43℃(±2℃) | working temperature | -40~+85℃ |

Maximum Power (PMAx) Temperature Coefficient | -0.34%/℃ | Maximum System Voltage | 1500V DC (IEC) |

Open-circuit Voltage (Voc) Temperature Factor | -0.25%/℃ |

| 1500V DC (UL) |

Short-circuit Current (Isc) Temperature Coefficient | 0.04%/℃ | Maximum Fuse-Rated Current | 35A |

ZMS Solar Panel Advantages

ZMS produces the best cross-mounted modules with ultra-high string power, increasing the power of a single string up to 37%, helping customers significantly reduce costs. Our innovation team has innovated the most advanced wafer products in the PV industry at the mass production level, 160mm, 180mm, and 210mm respectively.

This multi-dwelling grid technology, which requires MBB, allows monocrystalline solar panels to exert extremely high light utilization and stronger power collection capacity.

The average power is increased by 2~3% and the efficiency is increased by 0.4~0.6%.

The high-density module encapsulation technology adopted by ZMS ensures a perfect balance between efficiency and reliability, increasing module efficiency by 0.2~0.3%.

Cross-section after conventional cutting: rough cut surface with fine lines.

Cross-section after non-destructive cutting: smooth cutting surface without cracks.

Classification of Communication Cables by Usage

The photoelectric conversion efficiency of monocrystalline silicon solar panels is about 15%, and the highest reaches 24%. This is the highest photoelectric conversion efficiency among all kinds of solar panels.

Because monocrystalline silicon is generally encapsulated with tempered glass and waterproof resin, it is robust and durable, with a service life of 15 years in general and up to 25 years.

The production process of polycrystalline silicon solar panels is similar to that of monocrystalline silicon solar panels, but the photoelectric conversion efficiency of polycrystalline silicon solar panels is much lower.

Its photoelectric conversion efficiency is about 12% (July 1, 2004, Sharp Japan listed the world’s highest efficiency polycrystalline silicon solar panels with 14.8% efficiency).

In terms of production cost, it is cheaper than monocrystalline silicon solar panels, is easy to manufacture materials, and saves electricity consumption, the total production cost is lower, so it has been developed in large quantities.

Amorphous silicon solar panel is a new type of thin-film solar panel that appeared in 1976. It is completely different from monocrystalline silicon and polycrystalline silicon solar panels, the process is greatly simplified, silicon material consumption is very little, and electricity consumption is much lower.

Its main advantage is that it can generate electricity even in low-light conditions. However, the main problem of amorphous silicon solar panels is the low photoelectric conversion efficiency, the international advanced level of about 10%, and is not stable enough, with the extension of time, its conversion efficiency decay.

The Material Composition Of Solar Panels

Most bulk silicon PV modules consist of a transparent surface, an encapsulant, a backside, and a frame around the outer edge. In most modules, the top surface is glass, the encapsulant is EVA (ethylene vinyl acetate), the backside is PET, this is only for glass solar panels, the surface of flexible modules may be ETFE or PET, and the backside of SMD modules is PCB.

The surface of the front of the PV module must have a high light transmission in the wavelength range that can be used by the solar cells in the PV module.

For silicon solar cells, the top surface must have a high transmittance in the wavelength range of 350 nm to 1200 nm. In addition, the reflection from the front surface should be low.

Although in theory this reflection can be reduced by applying an anti-reflection coating to the top surface, in practice these coatings are not strong enough to withstand the conditions of use of most PV systems.

Another technique to reduce reflections is to “roughen” or texturize the surface. However, in this case, dust and dirt are more likely to adhere to the top surface and are less likely to be dispersed by wind or rain.

As a result, these components are not “self-cleaning” and the benefits of reduced reflection are quickly offset by losses due to increased dirt on the top surface.

In addition to reflection and transmission properties, the surface material should be impervious to water, should have good impact resistance, should remain stable under prolonged UV exposure, and should have low thermal resistivity.

Water or water vapor entering the PV module will corrode the metal contacts and interconnects, thus significantly reducing the lifetime of the PV module.

In most modules, the front surface is used to provide mechanical strength and stiffness, so the surface or rear surface must be mechanically stiff to support the solar cells and wiring.

There are several options for surface materials, including acrylic, polymer, and glass. Tempered, low-iron content glass is the most commonly used because it is low cost, strong, stable, highly transparent, impervious to water and gases, and has good self-cleaning properties.

Encapsulants are used to provide adhesion between the top surface and the rear surface of solar cells and photovoltaic modules. The encapsulant should be stable under high temperatures and high UV exposure.

It should also be optically transparent and should have a low thermal resistance.

EVA (ethylene vinyl acetate) is the most commonly used encapsulant. EVA is in the form of a thin sheet that is inserted between the solar cell sheet and the top and back surfaces. This interlayer is then heated to over one hundred degrees, causing the EVA to polymerize and bond the module together.

The main characteristic of the rear surface of a PV module is that it must have low thermal resistance and must be protected from the ingress of water or water vapor.

In most modules, a thin polymer sheet is used for the rear surface Some PV modules, called bifacial modules, are designed to receive light from the front or back of the solar cell. In bifacial modules, both the front and the rear must be optically transparent.

The final structural component of a solar panel is the bezel or frame of the solar panel. Conventional PV module frames are usually made of aluminum. The frame structure should be free of bumps that could cause water, dust or other substances to be trapped.

Indispensable Element

Photovoltaic Inverter

A photovoltaic (PV) inverter converts the variable DC voltage generated by photovoltaic (PV) solar panels into utility-frequency alternating current (AC) inverters, which can be fed back into the commercial transmission system or for off-grid grid use.

The PV inverter is one of the important balance of systems (BOS) in a PV array system and can be used in conjunction with normal AC-powered equipment.

Solar inverters have special features to work with PV arrays, such as maximum power point tracking and islanding effect protection.

Type | Model | |

Inverter | Centralization | 1600/2500/3125KW |

| / | Group String Type | SG225HX/SG250HX |

| / | / | SUN2O00-196KTL- HO/SUN2OO0-196K TL-H3 |

/ | SUNNY TRIPOWER 150-20 | |

Combiner Box | LONGMAX, 150OV HIGH CURRENT BENTEK CONNECTPV | |

Cable | 4MM2/6MM² | |

Photovoltaic System Racking

Solar photovoltaic racking, is a solar photovoltaic power generation system in order to place, install, fix solar panels designed special bracket.

General materials are aluminum alloy, carbon steel and stainless steel.

Solar support system related products made of carbon steel and stainless steel, carbon steel surface to do hot-dip galvanized treatment, outdoor use for 30 years without rust.

Solar photovoltaic support system is characterized by no welding, no drilling, 100% adjustable, 100% reusable.

Stationary Bracket | +5400Pa/-2400Pa、+3600Pa/-2400Pa |

Tracking Bracket | +2400Pa/-2400Pa、+2400Pa/-2400Pa |

ZMS Offers Solutions for Common Solar Panel Applications

PV + Wastewater Treatment Plant Energy Saving and Emission

Sewage treatment plants are energy-intensive, high-energy industries, and many of the world’s sewage treatment plants are still in the stage of energy consumption of electricity.

Treatment of each ton of sewage power consumption in the 0.2-0.3 degrees or so, the cost of electricity accounts for about 50% -70% of the cost of sewage treatment, if the enterprise through technical means reduces 30% of the power consumption, then you can reduce 18% of the cost of sewage treatment.

As the sewage treatment plant covers a large area, surrounded by open space, abundant light, and high power consumption, the construction of a distributed photovoltaic power station project has a unique advantage.

It can realize the effective use of space resources by adding photovoltaic modules on top of the roof, vacant land, parking space of the plant, and the work unit space of the sewage treatment plant such as rapid sedimentation tank, two sedimentation tanks, aerobic tanks, and biochemical tanks.

- Social Benefits

Enhancement of national energy security

Enhance the utilization rate of land resources - Economic benefits

Power Generation Efficiency

The plant area has open space, few obstructions, and maximizes the effective light hours, which maximizes the power generation efficiency of the PV modules.

Economic cost perspective

At present, the electricity consumption of the wastewater treatment plant is two kinds of electricity: flat section electricity consumption and peak-valley time-sharing electricity consumption. The cost of flat section electricity consumption is about 0.55 yuan/kWh, and the average daytime electricity consumption during peak-valley time-sharing is about 0.7 yuan/kWh.

Self-invested income

PV power generation is self-generation and self-consumption, prioritizing the use of electricity generated by PV, the reduction of daily electricity expenditure is equivalent to income.

Electricity Discount Mode

The difference between the discounted PV electricity tariff and the utility electricity is equivalent to revenue.

Leifeng Water Purification Plant

- Generated 3,469,000 KWh of electricity in the first year

- Estimated cumulative power generation over 25 years: 80,883,700 KWh

- Average annual power generation of 3,235,300 KWh

- According to the standard coal consumption of 309g of coal per kWh of thermal power, the construction and operation can save about 795.27t of standard coal per year, and reduce the emission of soot by about 1.00t, CO2 by about 1,988.17t, NXOY by about 5.57t and SO2 by about 5.82t per year.

- ZMS PV Module + Flexible Racking

Changing the purlin of traditional steel-based bracket program to steel strand method. Adopting the first-line method to provide pre-tension, the strand is allowed to have a certain deformation under different working stress conditions after module installation, thus realizing a large-span bracket of 10~30m, which can meet the needs of different terrains. - Photovoltaic Module + Independent Fish-belly Bracket

The intersecting steel cables are used as the establishment system, with the upper arch cable bearing the wind pressure and the lower sagging cable bearing the vertical load. Each cable structure forms an independent PV bracket unit. Support angles are set in the middle of the independent stall spacing, tripods are installed at the upper ends, the tripods are connected by steel cables, and the PV modules are installed on these cables. - Photovoltaic Module + Tensioned String Beam Racking

Axonometric drawing of Tensioned String Girder Rope Bracket (Optimum Inclination) The structure is similar to a fish-belly structure, where the different load bearing girders are fixed into a plane with purlins between them, and the modules are arranged in the plane to the optimum inclination or horizontally according to the need.

Communication base station energy saving and emission reduction program

ZMS believes that the process method of prioritizing power supply by photovoltaic, supplementing power supply by storage battery, and backing up power supply by oil generator can also greatly solve the problem of communication network coverage in remote areas, areas without electricity, areas with difficulty in drawing power from the utility, and areas with unstable utility power, and ensure the normal operation of base stations.

ZMS also encourages the innovation of photovoltaic communication intelligent new energy series, using photovoltaic power generation priority power supply, energy storage as a supportive power supply, the utility power into supplementary power supply, generator as a backup emergency power supply mode.

- Traditional base station utility power introduction faces difficulties.

- 5G grid is fully commercialized.

- Photovoltaic power generation system is stable in operation, high in reliability, long in service life, low in post operation cost, and simple in use and operation etc., it can be used as the power source of communication base station.

- The photovoltaic complementary system combining utility power + PV can not only reduce the cost of electricity for base stations, but also save energy and reduce emissions. And with the widespread use of telecommunications in modern society demand and importance of the telecommunications industry needs to minimize energy costs and minimize the environmental impact of the search for alternative to ordinary power off-grid energy solutions, solar photovoltaic power began to be used in the field of communications power supply.

Module:9750Wp(325Wpx30 pieces)

Controller: 1 set of photoelectric complementary controller

Battery: 500AH 2 sets

Racking:PV-up tower mounting

Advantages:

1 Module mounting directly on the tower, low installation cost.

2 PV power generation DC power supply, while ensuring power supply for DC loads, it can also charge the battery.

3 Peak and valley tariff charging and discharging management mode is adopted to realize energy saving and emission reduction.

Module:3240Wp(270WpX12pcs)

Controller: single-phase 4kW1set

Battery: single-phase grid-connected box 1 set

Racking: Ground-based photovoltaic racking

Advantages:

1 AC single-phase power supply.

2 When the utility power is normal, the PV power generation is prioritized to be connected to the grid to supply power for the communication equipment, and the excess power is connected to the Internet.

3 In case of abnormal utility power/blackout, PV power generation charges the battery to ensure the stability of DC power supply of communication system.

Photovoltaics and energy saving heating in the countryside

ZMS offers a combination of photovoltaic and rural solutions, paired with site-specific design solutions, and excellent structural design solutions that can significantly save installation time and reduce installation costs.

- Thermal Insulation and Heating

The modules on the roof can well reduce the indoor temperature, especially in summer, through the photovoltaic panels will be light energy into electricity, photovoltaic panels are equivalent to the heat insulation layer, measured can reduce the indoor temperature of 3-5 degrees. In winter, photovoltaic panels are equivalent to the building to wear a coat, to a certain extent can play a role in insulation. - Saving Electricity

In rural and urban income imbalance areas, if the rural house installed with photovoltaic power generation, self-generated self-consumption of surplus power grid mode, you can save most of the electricity consumption, but also to avoid the ladder tariffs.

You can save most of the electricity consumption and avoid the step tariff. You can have a large amount of money left over every year through photovoltaic power generation. - No Pollution No Noise

The electricity generated by the PV system is through inexhaustible solar energy, which does not produce any pollution and noise, and is truly energy-saving, environmentally friendly, and puts environmental protection into practical action. Each generation of photovoltaic power will save the corresponding mineral resources.

They are broadly categorized as follows:

Pitched Roof Installation Method – Bent Hook Bracket

Pitched roof installation – pulling forward and pulling backward

Flat Roof Installation – Anchored Legs

Flat Roof Installation – Counterweights

Each of the above installation methods has its own advantages in terms of cost and installation time. ZMS will customize the professional installation plan according to the customer’s needs and budget.

PV+Typical Common Plants

ZMS also offers a professional program for the installation and use of photovoltaic systems for factories commonly found in urban areas and street-level suburbs.

The working principle of this program is that the modules on the roof can reduce the indoor temperature very well, especially in summer, through the photovoltaic panels will be converted into electricity, photovoltaic panels are equivalent to the heat insulation layer, can be measured to reduce the indoor temperature of 3-5 degrees. In winter, the photovoltaic panel is equivalent to the building to wear a coat, to a certain extent can play a role in insulation.

- Extend the life of the roof

1 Photovoltaic modules on the surface of the roof to play a layer of protection, reduce the roof by direct sunlight produced by the material aging;.

2 Reduce the impact of hail on the roof. - Reduces indoor temperature

The PV module on the roof absorbs solar energy and converts it into electricity while reflecting and refracting the sun’s heat, which reduces the indoor temperature by 4-6 degrees and effectively reduces the energy consumption of air conditioning in the summer of the building, saving the energy consumption of air conditioning in the enterprise by about 30%-40%. - Revitalization of fixed assets

Some productive enterprises have hundreds of square feet or tens of thousands of square feet of roofs, and after installing photovoltaic on the roofs of industrial plants, these large areas of unused space become valuable resources, revitalizing the fixed assets of the enterprises and increasing more income for the enterprises. - Promote energy saving and emission reduction

After the construction of the power station can consume more photovoltaic electricity, minimize the application of traditional electricity, equivalent to more savings in standard coal, emission reduction of carbon dioxide and other air pollutants, in response to the blue sky strategy.

ZMS cable team customizes different PV system installations for different roofs.

ZMS cable team customizes different PV system installations for different roofs.

Photovoltaic + gas station energy saving and emission reduction

Zms is responsible for the energy saving and emission reduction program in the petroleum industry with the advantages of low carbon and environmental protection, reducing energy consumption, energy saving and emission reduction. Enterprises take the lead in low-carbon energy saving, which demonstrates the sense of corporate social responsibility. And it also saves costs and corporate electricity expenses, and enhances brand image and social awareness.

- Purpose of construction

To build a smoke-free city by supplying electricity for oil exploration

To supply power to oil employees’ supporting facilities - Advantages of Power Supply

Meet the demand for electricity in oil exploration and reduce energy consumption.

Increase operating income by buying back surplus electricity from the Internet

- Heating and maintaining crude oil above 50C for storage in tanks and maintaining crude oil fluidity.

Power supply for crude oil heat exchanger, circulating pump, thermal storage system, water jacket heater and control system. - A heat storage tank with a volume of 5 m3 was selected to store the excess heat for use in the absence of solar radiation.

- Under the working pressure of 0.4—0.78MPa, keep the temperature of crude oil in the pipeline stable above 55℃.

- Purpose of construction

To supply power to the staff and ancillary facilities of the gas station

Power supply for electric vehicle charging piles - Advantages of power supply

Satisfy the power demand of the gas station itself and reduce energy consumption.

Buying back the remaining electricity from the Internet, increasing the operating income of the gas station.

Service of ZMS Company

Over Productions Service

ZMS has a wide range of cable and wire products for you to choose from. We will provide caring services and professional project solutions for everyone who needs them.

Quality Certification Services

ZMS cable products are manufactured according to GB, IEC, BS, NFC, ASTM, DIN, and other international standards. Our technical team can customize cable products that meet your requirements according to your need.

Profession Customer Service

ZMS provide free professional consulting services to provide you with one-stop project solution services and rapid product delivery solutions.

Delivery And Shipping Services

While ZMS provides high-quality cables, we also provide good delivery solutions. While ensuring the safe delivery of products, we provide the best packaging and transportation solutions, greatly reducing customers’ transportation costs.

Packaging of ZMS

ZMS cables packaging are provided in the form of wooden reels, corrugated boxes and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.