High Voltage DC Cable

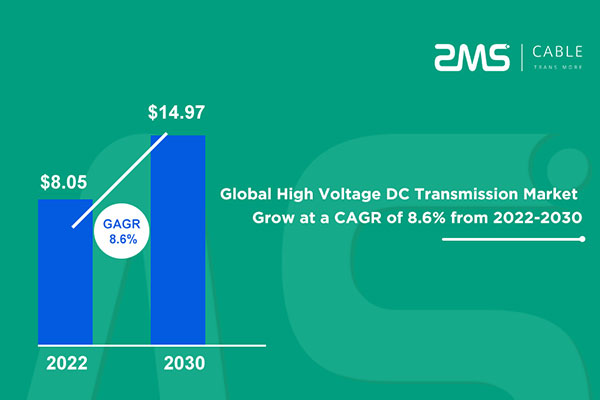

High Voltage DC Cable (HVDC) is a vital component of modern power transmission systems. Unlike traditional HVAC cables, HVDC cables are designed to transmit electrical energy in direct current form, offering higher efficiency and lower losses, especially over long distances and in subsea installations. ZMS Cable has over 30 years of manufacturing and exporting experience, providing advanced HVDC cable solutions that comply with international standards such as IEC and VDE.

Introduction

With the widespread expansion of renewable energy projects, offshore wind farms, and cross-border power grids, demand for HVDC cables continues to grow. ZMS’s HVDC cables are widely used in submarine interconnectors, offshore platforms, and large-scale urban energy transmission projects.

At ZMS, we provide not only cables but also complete energy transmission solutions, ensuring our customers benefit from reliable quality, competitive pricing, and professional technical support.

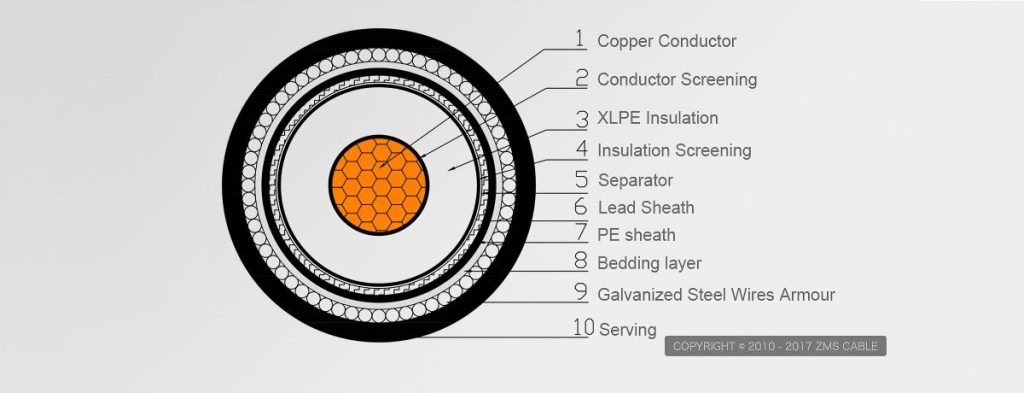

HVDC Cable Structure

The performance and reliability of HVDC cables depend largely on their internal structure. Each layer is carefully designed to ensure safe operation under extreme environments and mechanical stresses.

ZMS’s typical HVDC cable structure:

- Conductor — Made of copper or aluminum, it is the core component for transmitting high-voltage DC power, offering minimal resistance.

- Conductor Shield — A semiconducting layer surrounding the conductor, smoothing the electric field and preventing stress concentrations.

- Insulation — The most critical component of the cable, typically made of cross-linked polyethylene (XLPE) or bulk impregnated (MI) paper, designed to withstand extremely high DC voltages.

- Insulation Shield — Another semiconducting layer located outside the insulation, further controlling the electric field distribution.

- Metallic Sheath — A layer of copper or lead alloy that provides mechanical protection and prevents the intrusion of water and moisture.

- Outer sheath—The final protective layer, typically polyethylene (PE), resists corrosion, abrasion, and environmental damage. These structures work together to enable HVDC cables to achieve long-distance transmission, high-capacity power transmission, and operate safely in harsh environments such as deep sea or urban underground systems.

- Armor (for subsea or underground use) — Steel wire or steel tape that protects the cable from external forces, such as seabed pressure, fishing activities, or construction impacts.

Types of ZMS High Voltage DC Cables

HVDC cables are classified into various types based on insulation technology, rated voltage, and application environment. ZMS Cable offers a comprehensive range of HVDC cables, including solutions for submarine, underground, and high-voltage XLPE applications, tailored to power transmission projects worldwide.

HVDC Subsea Cable

HVDC submarine cables are specifically designed for underwater applications and can withstand extreme pressure, mechanical stress, and the harsh conditions of marine environments.

Insulation: Mass-impregnated (MI) paper or advanced XLPE.

Applications: Offshore wind farms, island interconnections, cross-border submarine power links.

Advantages:

- Reliable for long-distance undersea transmission.

- Excellent mechanical protection and corrosion resistance.

- Lower transmission losses over hundreds of kilometers.

ZMS has extensive experience in exporting HVDC submarine cables for deep-sea projects, ensuring compliance with IEC and CIGRÉ standards and providing solutions that include design, testing, and installation support.

525 kV HVDC Cable

We also manufacture and export ultra-high voltage DC cables, such as 525 kV DC cables, designed for high-capacity, long-distance power transmission.

Insulation: XLPE or MI paper, engineered to handle very high DC voltage stresses.

Applications: Large-scale interconnectors, national grid transmission, and offshore renewable energy projects.

Advantages:

- Capable of transmitting up to 2000 MW per cable system.

- Minimizes energy losses over thousands of kilometers.

- Supports both underground and submarine installations.

Our 525 kV HVDC cable solutions can be customized for each project, ensuring optimal performance and long-term reliability.

HVDC Underground Cable

High-voltage DC underground cables are designed for urban or land power transmission where the use of overhead lines is unsuitable or prohibited. They are different from other high-voltage DC cables in terms of buried structure.

Insulation: XLPE or MI technology with protective metallic sheath and armoring.

Applications: City power supply, industrial zones, and underground grid interconnections.

Advantages:

- Reduces visual and environmental impact.

- Provides high reliability and safety in densely populated areas.

- Suitable for long-distance underground transmission.

ZMS provides high-quality HVDC underground cables with advanced insulation and armouring technology, ensuring durability and compliance with international safety standards.

HVDC XLPE Cable

HVDC XLPE cable refers to HVDC cable insulated with cross-linked polyethylene, which is a modern and environmentally friendly alternative to oil-immersed MI cable.

Applications: Both submarine and underground projects, offshore wind farms, and urban grids.

Advantages:

- Lighter and more flexible, easier to install.

- Maintenance-free and environmentally friendly.

- Excellent electrical performance under high DC voltage.

ZMS manufactures and exports high-quality HVDC XLPE cables, which are rigorously tested for partial discharge, impulse voltage, and long-term aging, ensuring safe operation in harsh environments.

HVDC vs. HVAC Cable

Feature | HVDC Cable | HVAC Cable |

Transmission Distance | Efficient over 1000 km+ | Limited to ~500 km |

Power Losses | Lower | Higher |

Cable Charging Current | None | Significant |

Submarine Application | Preferred | Rarely used |

Interconnection of Grids | Possible | Not possible |

Installation Cost | Higher initial investment | Lower short distance cost |

High-voltage DC cables are the most efficient solution for long-distance, high-capacity transmission projects, offering lower losses, stable voltage, and the advantage of connecting to asynchronous grids. In contrast, high-voltage AC cables are suitable for shorter distances but suffer from higher transmission losses and reactive power issues. For submarine, underground, and UHV projects, ZMS HVDC cables offer reliable performance, advanced insulation properties, and customized solutions, making them the preferred choice for modern power infrastructure.

Technical Specifications of HVDC Cable

Parameter | Typical Value |

Rated Voltage | ±320 kV / ±500 kV / ±800 kV |

Conductor Material | Copper / Aluminum |

Conductor Size | 800 – 2500 mm² |

Insulation Type | XLPE / MI |

Max Transmission Capacity | Up to 2000 MW |

Installation | Submarine / Underground / Overhead |

Operating Temperature | -30°C to +90°C |

HVDC Cable Standards & Testing

High-voltage direct current (HVDC) cables are critical components of modern power transmission systems. Their design, manufacture, and performance must adhere to strict international standards and rigorous testing procedures. At ZMS Cable, we ensure that every HVDC solution meets the highest quality benchmarks for reliability, efficiency, and long-term stability.

International Standards for HVDC Cables

To ensure safety and performance, HVDC cables are manufactured in accordance with leading standards, including:

IEC standards—IEC 62895, IEC 62067, and IEC 62933—cover the design, testing, and operation requirements for HVDC land and submarine cables.

CIGRÉ standards—provide technical advice for HVDC submarine cable systems and type approval.

VDE and IEEE standards—ensure compliance with common European standards for insulation, withstand voltage, and safety.

Project-specific standards—customized testing protocols based on customer requirements and environmental conditions, particularly for submarine and underground HVDC cable installations.

HVDC cable testing ensures long-term safety, reliability, and efficiency. Each cable undergoes type tests (electrical, thermal, and mechanical), routine tests on every production length, and sample tests to verify long-term performance. Special tests, such as deep-water pressure or fire-resistance tests, are conducted for submarine and underground HVDC projects. At ZMS Cable, all HVDC submarine, subsea, underground, and 525 kV XLPE cables are tested in compliance with IEC and CIGRÉ standards to guarantee stable operation over decades.

Why Choose ZMS High Voltage DC Cables?

Full Voltage Range

Customized Solutions

Strict Quality Control

30+Years Export Experience

ZMS Cable Company Service

Over Productions Service: ZMS has a wide range of cable and conductor products for you to choose from. We will provide caring services and professional project solutions for everyone who needs them.

Quality Certification Services: ZMS cable products are manufactured according to GB, IEC, BS, NFC, ASTM, DIN, and other international standards. Our technical team can customize cable products that meet your requirements according to your needs.

Profession Customer Service: ZMS provides free professional consulting services to provide you with one-stop project solution services and rapid product delivery solutions.

Delivery And Shipping Services: While we at ZMS provide high-quality cables, we also provide good delivery solutions. While ensuring the safe delivery of products, we provide the best packaging and transportation solutions, greatly reducing customers’ transportation costs.

Packaging of ZMS: ZMS cable packaging is provided in the form of wooden reels, corrugated boxes, and coils. The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.

Ready to Power Your Project with Reliable HVDC Cables?