In modern industry, power generation, and communications, cables serve as crucial media for transmitting electrical energy and signals. Their performance and lifespan are directly linked to the safety and stability of the entire system. When selecting cables, many people often focus solely on voltage rating, current carrying capacity, or price, overlooking the crucial parameter of bend radius. In reality, bend radius not only affects cable installation ease but also directly determines its mechanical and electrical performance, even impacting its lifespan and safety. This article will comprehensively explain why bend radius is so important in cable selection, from multiple perspectives: conceptual analysis, performance impact, practical applications, and selection guidelines.

What Is The Cable Bend Radius?

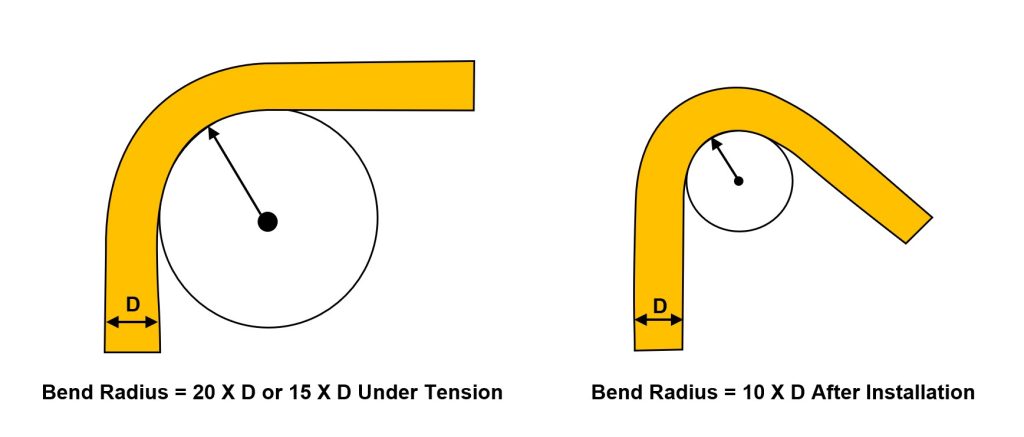

The bend radius is the minimum radius formed by the cable’s centerline when it is bent. During cable installation, if the bend radius is smaller than the design requirement, it can easily cause excessive stress inside the cable, resulting in mechanical damage. When selecting cables, people often rely on intuition and experience to determine the appropriate bend radius for their application. However, the selection of cable bend radius requires multiple tests and the consultation of professional cable technicians; it should never be based on intuition.

Typically, the minimum bend radius of a cable is expressed as a multiple of the cable’s outer diameter, such as “6 x cable outer diameter” or “12 x cable outer diameter.”

Bend radius requirements vary depending on the type of cable. For example, flexible cables can tolerate smaller bend radii, while high-voltage wires or fiber optic cables require larger bend radii for safety and performance.

Effect of Bend Radius on Cable Performance

Conductor Damage

Cable conductors typically consist of multiple strands of copper or aluminum wire. When the bend radius is too small, the conductors are stretched or compressed, making them susceptible to breakage or permanent deformation. Frequent bending within a narrow radius can accelerate the wear and tear of multi-core flexible cables, affecting their conductivity and even causing electrical failures.

Insulation Layer Damage

The primary function of a cable’s insulation layer is to isolate the conductor from the outside world, preventing short circuits and electrical leakage. When the bend radius is too small, the insulation layer is subjected to tension, compression, or shear, potentially causing microcracks or even outright rupture. This not only degrades the cable’s insulation performance but can also cause electrical leakage, short circuits, or even damage to equipment over long periods of use. Loss of insulation in cables that require it can result in serious electrical leakage.

Signal Transmission Quality Deteriorates

For shielded or control cables, a too-small bend radius can affect the geometric relationship between the shield and conductor, leading to increased electromagnetic interference (EMI), accelerated signal attenuation, and impacted communication and control system stability. For example, if data communication cables are frequently bent and do not meet minimum bend radius requirements, signal loss can increase significantly.

The abstract terms “geometric relationship,” “electromagnetic,” and “signal loss” can obscure the consequences of an excessively small bend radius. ZMS will explain these concepts in the next article.

Reduced Cable Life

Long-term bending at a tight radius causes the cable’s internal conductors and insulation to experience repeated stress cycles. This mechanical fatigue can shorten the cable’s lifespan, increase maintenance costs, and in severe cases, lead to premature failure, resulting in production downtime or safety hazards.

Bending Radius Requirements for Different Cable Types

Different types of cables have different structures and uses, and their minimum allowable bend radius also varies.

The following are the bend radius requirements for common cable types:

| Cable types | Recommended minimum bending radius | Application |

| Low voltage cable | ≥ 6×cable outer diameter | Suitable for general buildings and factory wiring |

| High voltage cable | ≥ 12×cable outer diameter | Large size, heavy weight, large bending force, sufficient space must be reserved |

| Flexible cable | ≥ 4–6×cable outer diameter | Used for dynamic drag chains, robots, etc., allowing for smaller bending radius |

| Fiber optic cable | ≥ 10–20 × cable outer diameter (depending on single-mode/multimode) | Too small a bend will increase optical loss and affect signal transmission |

Note: The data in the table are common cable bending radii. For some special structures that meet the voltage requirements, the bending radius may be different. You are welcome to provide your project plan and discuss with ZMS technicians for specific data.

The Importance of Cable Bending Radius in Actual Installation

When Installation Space is Limited

When routing cables through cabinets, elevator shafts, bridges, or confined ducts, if the bend radius is insufficient, the cables may not fit smoothly through the installation path. Considering the bend radius in advance can ensure a smooth installation and avoid rework or damage to the cables.

In Dynamic Application Scenarios

Cables are frequently bent in industrial automation production lines, robots, cranes, and other equipment. If the selected cable has a large bend radius or is not suitable for dynamic applications, conductor fatigue, shield damage, or signal loss can occur. ZMS offers specialized, flexible, or drag chain cables designed with dynamic bend radius in mind.

Reduce Maintenance Costs

Adhering to bend radius requirements when routing cables can reduce the risk of cable damage and failure, lowering repair and replacement costs. This is especially true for high-voltage cables or fiber optic cables, as damage can be costly to repair and can even affect the operation of the entire system.

Bending Radius and Cable Current Carrying Capacity & Safety

The bending radius not only affects the external mechanical properties of the cable, but also indirectly affects the electrical performance:

Influence of Current Carrying Capacity

Too small a bend will cause local stress on the conductor and uneven heat dissipation, which may increase the temperature rise and reduce the actual load-bearing capacity of the cable.

Safety Hazards

Conductor breakage, insulation breakdown, or shielding damage can lead to electrical accidents, including short circuits, current leakage, or fire risks.

Therefore, in cable design and selection, the bending radius must be taken as a key criterion and comprehensively considered together with the current carrying capacity, voltage level, environmental conditions, etc.

How to Determine the Bending Radius When Selecting Cables

Measuring the Installation Space

When designing a wiring plan, first measure the bending radius of the installation space to ensure that the cable will not be less than the minimum bending radius in actual wiring.

View Manufacturer’s Specification Sheet

Usually, cable manufacturers will clearly mark the minimum bending radius in the specification, especially for flexible cables and drag chain cables. This is an important basis for cable selection.

Flexible Cables Preferred for Dynamic Environments

For environments that require frequent bending, choose flexible or drag chain-specific cables that can withstand a smaller bending radius while ensuring lifespan and signal stability.

Ensure Sufficient Bending Space for HV & Large Cross-Section Cables

High-voltage cables and cables with large cross-sections are large in size and heavy in weight, so sufficient bending radius must be reserved during wiring to avoid construction difficulties and subsequent maintenance problems.

Comply With Standards & Regulations

In addition to the above precautions, you must also refer to the bending radius regulations in international standards (IEC, UL) or national standards (GB/T) to ensure that the installation complies with safety regulations.

Common Misconceptions

The Smaller the Bending Radius, the Better

This conclusion is completely wrong. In fact, a bending radius that is too small will damage the cable and increase the risk of failure, which is not worth the cost.

All Cables Have The Same Bend Radius

As shown in the table above, the bending radius of cables is not only different, but also varies greatly, so they must be selected according to the specifications.

Focus only on Voltage & Current Carrying Capacity

Excessive focus on safety and current carrying capacity, while ignoring mechanical installation conditions and bend radius, can lead to installation difficulties and safety hazards. Choosing the right cable requires very comprehensive data, not just a few data points.

When selecting cables, bend radius is a critical parameter that cannot be ignored. It not only affects the ease of cable installation but also directly impacts the cable’s mechanical safety, electrical performance, and service life. Choosing the right cable and adhering to minimum bend radius requirements can:

- avoid conductor breakage and insulation damage

- improve signal transmission stability

- extend cable life

- reduce maintenance costs

ensure safe and stable system operation. Overall, bend radius is not only a reference parameter for engineering design but also a crucial criterion for ensuring cable performance and system safety. Considering the bend radius during the selection, procurement, and installation process is crucial for every engineer and procurement personnel.