H07V-K is a single-core, highly flexible, 450/750V rated cable intended for distribution cabinets, control cabinets, switchgear, and internal wiring for power transmission. It is designed to meet EN 50525-2-31 or IEC standards and offers excellent flexibility and durability for fixed wiring and electrical applications requiring flexible connections.

Table of Contents

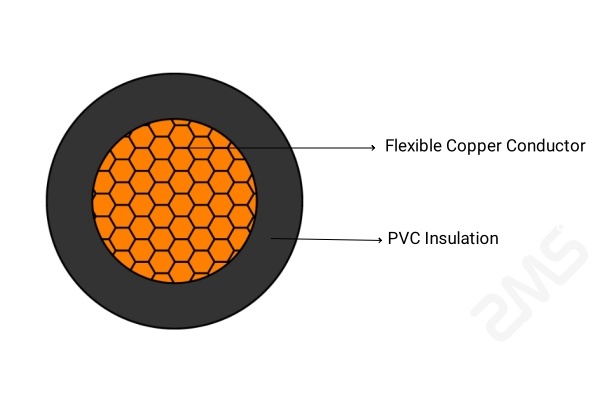

ToggleH07V-K Cable Structure

| Structure Composition | Materials & Specifications |

| Conductor | Material: annealed copper (according to EN 60228 Class 5) |

| Construction: fine stranded copper wire, highly flexible | |

| Insulation | Material: PVC (polyvinyl chloride) |

| Thickness: 0.6mm~1.4mm (adjusted according to conductor cross-sectional area) | |

| Color Coding | Single color (red, yellow, blue, black, etc.) or with green/yellow stripe (ground wire) |

H07V-K Wire Application

Power Distribution: fixed wiring inside buildings, distribution box connections.

Industrial Equipment: fixed wiring of motors, transformers, and control cabinets.

Lighting Systems: interior lighting circuits, fixture installations.

Limitations: Not applicable to outdoor direct burial, mobile equipment, or exposure to UV/mechanical stress.

Performance Characteristics

Highly Flexible: Class 5 fine stranded copper conductors, easy to bend and install.

High Temperature Resistance: Long-term resistance to 70°C and short-term resistance to 160°C short-circuit temperatures.

Chemical Resistance: PVC insulation is resistant to oil, acid, alkali, and humid environments.

Safety Certification: CE, RoHS, IEC compliant, low smoke, and halogen free (optional).

H07V-K Technical Parameters

| Parameters | Specification |

| Rated Voltage (U₀/U) | 450/750 V |

| Conductor Cross Section | 1.5 mm², 2.5 mm², 4 mm², 6 mm², 10 mm², 16 mm², 25 mm², 35 mm², 50 mm², 70 mm², 95 mm², 120 mm², 150 mm², 185 mm², 240 mm², 300 mm², 400 mm² |

| Conductor Material | Annealed copper (according to EN 60228 Class 5) |

| Insulation | PVC (polyvinyl chloride) |

| Insulation Thickness | 0.6 mm ~ 1.4 mm (adjusted for conductor cross-sectional area) |

| Operating Temperature Range | -30°C ~ +70°C |

| Short-Circuit Tolerance Temperature | ≤ +160°C (max. 5 sec.) |

| Pressure Resistance Tests | 2000 V AC (50 Hz, 5 minutes) |

| Bending Radius | ≥ 6 times cable diameter (fixed installation) |

| Flame Retardant Grade | Conforms to IEC 60332-1 (single vertical flame) |

| Conductor Resistance | Compliance with EN 60228 (e.g. 2.5 mm² conductor resistance ≤ 7.41 Ω/km) |

| Insulation Resistance | ≥ 0.010 MΩ-km (at 20°C) |

| Environmental Certification | RoHS compliant, Low Smoke Zero Halogen (LSZH) version available |

Notes:

Voltage Class: 450/750 V means the cable is suitable for low voltage power systems, U₀ is conductor-to-ground voltage, and U is inter-conductor voltage.

Cross-Sectional Area: The common specifications are 1.5 mm² ~ 400 mm², the specific selection depends on the load current and the installation environment.

Temperature Range: Regular operating temperature is -30°C ~ +70°C, suitable for most indoor environments.

Voltage Withstand Test: 2000 V AC test ensures the insulation performance of the cable under high voltage.

Security and Certification

Certification Standards: HD 21, IEC 60227, EN 50525.

Installation Recommendations: Avoid overstretching, use wireway/casing protection, and ensure reliable grounding.

Environmental Protection: RoHS compliant, Low Smoke Zero Halogen (LSZH) version available on some models.

The difference between the H07V-K cable and the H05V-K model is that the H05V-K is rated at 300/500V for lower power scenarios. Regarding the color selection of the cable, the H07V-K cable’s multiple color markings are used to differentiate between the lines in the distribution line and do not affect its electrical properties, etc.