In modern power transmission and communications systems, cable performance and reliability depend heavily on the precise formulation of insulation and jacketing materials during production. From submarine cables traversing deep seas to fiber optic and communications cables supporting high-speed data transmission, each cable type faces unique environmental and operational challenges.

The choice of insulation and jacketing materials directly impacts a cable’s mechanical strength, electrical performance, thermal stability, and long-term durability. As a leading global cable manufacturer, ZMS Cable is committed to crafting high-quality cables by carefully adjusting material formulations to ensure reliable power and data transmission even under the harshest conditions.

The Role of Cable Insulation and Jacketing Materials

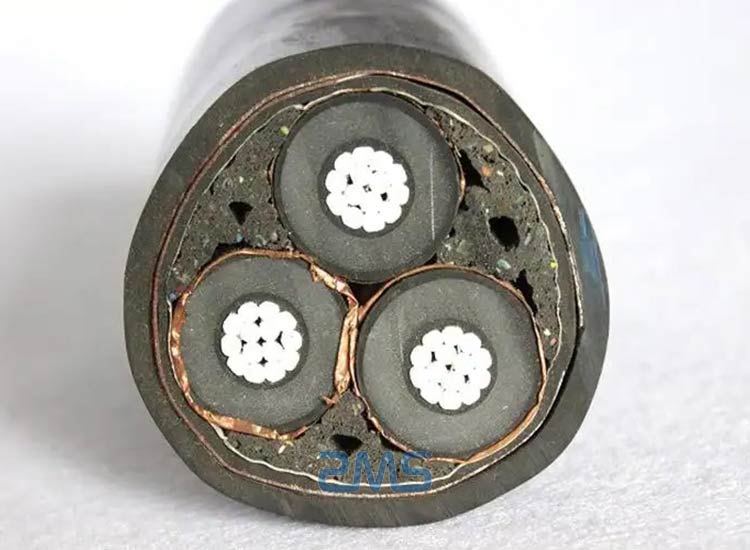

The insulation layer of a cable acts as a dielectric barrier, preventing current leakage, maintaining voltage integrity, and enhancing safety. The jacket, on the other hand, provides mechanical protection and environmental durability, shielding the cable from external forces, chemicals, and moisture.

Different application environments require different material properties:

Traditional cables require excellent dielectric strength and heat resistance.

Submarine and ocean cables require strong resistance to water immersion, as well as corrosion from salt and acids. Fiber optic cables prioritize low attenuation, lightweight, and flexibility.

Communication and data cables require signal stability and electromagnetic shielding performance during the manufacturing process.

Thus, the formulation and structural design of insulation and jacketing materials must be carefully optimized for each specific cable type.

Submarine Cables: The Challenge of Moisture and Corrosion Resistance

Submarine power and communication cables operate in one of the harshest environments on Earth—the deep sea. High voltage, salinity, and acidic microbial activity constantly threaten the cables’ structural integrity.

To ensure reliable performance, submarine cable insulation and jacketing materials must possess the following properties:

Excellent moisture resistance to prevent water molecules from penetrating the insulation layer.

High corrosion resistance to resist erosion by seawater and marine organisms.

High mechanical strength to withstand compression, abrasion, and bending stresses during installation and operation.

For example, cross-linked polyethylene (XLPE) is widely used as the insulation material for submarine power cables due to its excellent electrical properties and thermal stability. Polyethylene (PE) or polyurethane (PU) is also often chosen as an outer jacket material due to its excellent waterproof and mechanical properties. ZMS Cable continuously optimizes these compound formulations, adding preservatives, antioxidants, and water-blocking additives to improve cable life and reliability in marine conditions, with significant results. Our marine and submarine cable products have been successfully deployed in offshore wind farms, island power grids, and submarine communication systems worldwide.

Fiber Optic Cable: Balancing Protection and Flexibility

Fiber optic cables are highly sensitive to humidity, temperature, and mechanical stress. The choice of insulation and jacketing materials directly impacts signal attenuation, transmission stability, and service life.

Typical constructions include a tight or loose tube layer, a water-blocking element, and an outer jacket made of low-smoke zero-halogen (LSZH) or polyethylene (PE) materials.

LSZH compounds are particularly suitable for indoor or crowded environments because they generate minimal smoke and toxic gases in the event of a fire. Polyethylene (PE) jackets, on the other hand, offer excellent UV and weather resistance, making them ideal for outdoor optical cables.

ZMS Cable utilizes advanced polymer modification technology to produce optical cable materials with enhanced flexibility, environmental resistance, and UV resistance. This ensures stable data transmission over long-distance communication networks and in harsh outdoor conditions.

Communication Cables: Shielding and Fire Protection

For communication cables, especially those used in buildings, data centers, and industrial facilities, two factors are crucial: electromagnetic shielding and fire protection.

Cable insulation materials such as PVC (polyvinyl chloride) or LSZH (low-smoke, halogen-free) compounds offer excellent dielectric properties and flame retardancy. The sheath can also feature an aluminum foil shield, braided shield, or conductive tape to reduce signal interference.

ZMS Cable manufactures communication and control cables using specially developed halogen-free flame-retardant compounds that comply with international standards such as IEC 60332, IEC 60754, and IEC 61034. These compounds offer low smoke emissions, no corrosive gases, and enhanced electrical stability even in the event of a fire, providing a safe and reliable communication infrastructure for modern applications.

Material Innovation: The Key to Improving Cable Performance

Continuous improvements in insulation and sheathing materials are the foundation of cable innovation. Improved material properties can result in:

Higher withstand voltage and lower dielectric loss. Extend cable life and reduce maintenance costs.

Enhance fire, moisture, or chemical resistance.

Improve mechanical flexibility for complex installations.

The ZMS Cable team established early and long-term partnerships with composite manufacturers to develop custom polymer formulations that meet specific industrial needs. From thermoset cross-linked polyethylene (XLPE) and thermoplastic elastomers (TPE/TPU) to environmentally friendly low-smoke zero-halogen (LSZH) composites, ZMS offers complete project solutions for a wide range of power, communications, and specialty cables.

ZMS Cable’s products are widely used in:

Submarine power transmission – corrosion-resistant cross-linked polyethylene (XLPE) and polyethylene (PE) composite cables for subsea energy projects.

Fiber optic communications – UV-resistant, flexible, low-smoke, zero-halogen materials for indoor and outdoor installations.

Industrial control systems – flame-retardant and oil-resistant cables for automation equipment.

Renewable energy – weather-resistant and heat-resistant cables for solar and wind farms. Every ZMS cable is designed and tested according to international standards such as IEC, BS, and ASTM, ensuring superior quality and long-term reliability in a variety of applications.

The insulation and jacketing materials used in a cable determine its electrical reliability, mechanical durability, and environmental suitability. Whether it’s submarine cables requiring extreme corrosion resistance, optical cables demanding low signal loss, or communications cables prioritizing fire safety, selecting the right materials is critical to performance.

With advanced formulation technology, rigorous testing, and global experience, ZMS Cable is a trusted partner to the cable industry, providing customized cable solutions to meet the ever-changing demands of power transmission and data communications.

About ZMS Cable

ZMS Cable is a professional manufacturer and global supplier of power cables, communications cables, submarine cables, and related accessories. With a strong R&D team and state-of-the-art production facilities, ZMS provides high-quality cable products and customized solutions to customers in over 100 countries.

If you’re looking for durable, high-performance cables made with advanced insulation and jacketing materials, ZMS Cable is your reliable choice. Contact ZMS Cable today to learn more about our submarine, fiber optic, and communications cable solutions designed to perform in any conditions.